12

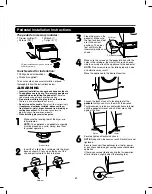

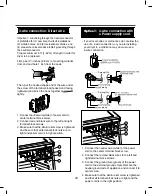

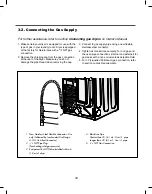

3-2. Connecting the Gas Supply

2

3

5

1

4

1. Make certain your dryer is equipped for use with the

type of gas in your laundry room. Dryer is equipped

at the factory for Natural Gas with a

3

/

8

Ó NPT gas

connection.

2. Remove the shipping cap from the gas connection

at the rear of the dryer. Make sure you do not

damage the pipe thread when removing the cap.

3. Connect to gas supply pipe using a new flexible

stainless steel connector.

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal and external) for

gas leaks with a non-corrosive leak detection fluid.

5. For LP(Liquefied Petroleum) gas connection, refer

to section on Gas Requirements.

For further assistance, refer to section

1 New Stainless Steel Flexible Connector - Use

only if allowed by local codes (Use Design

A.G.A. Certified Connector)

2

1

/

8

NPT Pipe Plug

(for checking inlet gas pressure)

3 Equipment Shut-Off Valve-Installed within 6

(1.8 m) of dryer

4 Black Iron Pipe

Shorter than 20 (6.1 m) - Use

3

/

8

pipe

Longer than 20 (6.1 m) - Use

1

/

2

pipe

5

3

/

8

NPT Gas Connection

Connecting gas dryers

on Owner's Manual

Summary of Contents for DLE3170W

Page 10: ...10 1 2 5 cm 3 8 9 cm Option 1 0 ...

Page 18: ...18 GN YL 3 WIRE SYSTEM EARTH 4 WIRE SYSTEM X1 X2 CN11 CN11 X1 X2 7 WIRING DIAGRAM ...

Page 23: ...23 8 4 Troubleshooting with Error ...

Page 24: ...24 ...

Page 25: ...25 ...

Page 26: ...26 ...

Page 27: ...27 ...

Page 28: ...28 ...

Page 29: ...29 ...

Page 30: ...30 ...

Page 35: ...35 Test 2 Thermistor Test Measure with Power Off ...

Page 36: ...36 Test 3 Motor Test ...

Page 37: ...37 6AIJ ...

Page 38: ...38 Test 5 Door switch test ...

Page 39: ...39 Test 6 Heater switch test Electric Type ...

Page 40: ...40 ᅐ Test 7 GAS Valve test Gas Type ...

Page 47: ...47 DRYER EXHAUST CHANGE 1 2 3 4 5 Note ...

Page 50: ...12 EXPLODED VIEW 50 12 1 Control Panel and Plate Assembly A210 A211 A130 A120 A140 A110 ...