22

Air Conditioner

Installation

Lo

Hi

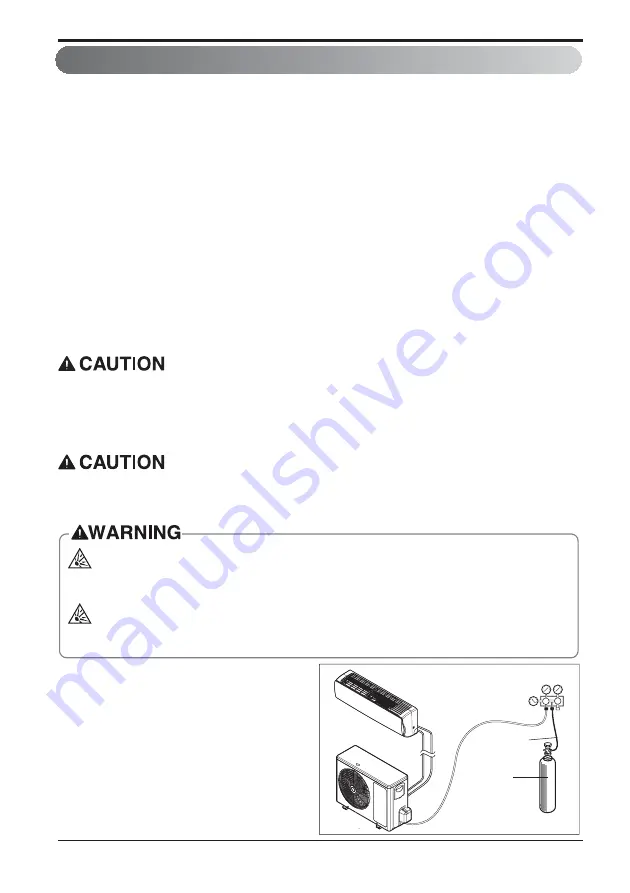

Indoor unit

Outdoor unit

Manifold valve

Charge hose

Nitrogen gas

cylinder(in vertical

standing position)

Pressure

gauge

Air Purging

The air and moisture remaining in the refrigerant system have undesirable effects as indicated below.

1. Pressure in the system rises.

2. Operating current rises.

3. Cooling(or heating) efficiency drops.

4. Moisture in the refrigerant circuit may freeze and block capillary tubing.

5. Water may lead to corrosion of parts in the refrigeration system.

Therefore, after evacuating the system, take a leak test for the piping and tubing between the

indoor and outdoor unit.

Air purging with vacuum pump

1. Preparation

• Check that each tube(both liquid and gas side tubes) between the indoor and outdoor units have been

properly connected and all wiring for the test run has been completed. Remove the service valve caps

from both the gas and the liquid side on the outdoor unit. Note that both the liquid and the gas side

service valves on the outdoor unit are kept closed at this stage.

2. Leak test

• Connect the manifold valve(with pressure gauges) and dry nitrogen gas cylinder to this service port with

charge hoses.

Be sure to use a manifold valve for air purging. If it is not available, use a stop valve for this

purpose. The knob of the 3-way valve must always be kept close.

• Pressurize the system to maximum 250 P.S.I.G. (R-22 model) or 400 P.S.I.G. (R-410A model)

with dry nitrogen gas and close the cylinder valve when the gauge reading reaches 250 P.S.I.G.

(R-22 model) or 400 P.S.I.G. (R-410A model). Next step is leak test with liquid soap.

To avoid nitrogen entering the refrigerant system in a liquid state, the top of the cylinder must be

higher than its bottom when you pressurize the system. Usually, the cylinder is used in a vertical

standing position.

Itmay cause explosion or injury.

After pump down, power must be turned off before removing the pipe. When operating this

product without connecting the pipe, there will be high pressure inside the compressor due

to the entry of air, possibly causing explosion or injury.

There is a risk of fire and explosion.

Insert gas (nitrogen) should be used when you check plumbing leaks, cleaning or repairs of

pipes etc. If you are using combustible gases including oxygen, product may have the risk

of fires and explosions

1. Do a leak test of all joints of the tubing

(both indoor and outdoor) and both gas

and liquid side service valves. Bubbles

indicate a leak. Be sure to wipe off the

soap with a clean cloth.

2. After the system is found to be free of

leaks, relieve the nitrogen pressure by

loosening the charge hose connector at

the nitrogen cylinder. When the system

pressure is reduced to normal, discon-

nect the hose from the cylinder.

Summary of Contents for AMNW12GRBL0

Page 28: ......