39

W

ater Piping System Installation

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Particles

Water

Circulating Water

Cold Water

pH (77°F [25°C])

6.5 - 8.0

6.5 - 8.0

Conduction Rate (77°F [25°C] μs/cm)

500 or below

200 or below

Alkali Level (ppm)

100 or below

50 or below

Hardness (ppm)

100 or below

50 or below

Chlorine Ion (ppm)

100 or below

50 or below

Lactic Acid Ion (ppm)

100 or below

50 or below

Iron (ppm)

0.1 or below

0.3 or below

Sulfur Ion (ppm)

Must not be detected

Must not be detected

Ammonium Ion (ppm)

0.5 or below

0.2 or below

Silica (ppm)

50 or below

30 or below

Table 11: Chiller Water Standards.

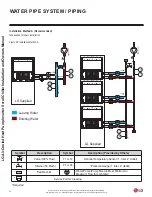

Water Pipe Installation

•

Appropriate pressure of the pipe flange connection is ≤145 psi.

• Water pipe size must be the same or larger than that of the chiller. When multiple chillers are manifolded together, piping is to be properly

sized and engineered by a licensed professional.

• To prevent the water pipe connections from sagging due to the load, install appropriate pipe supports.

• Position the water inlet pipe at the bottom of the water pipe system, and position the outlet pipe at the top of the water pipe system.

• If there is a risk of condensation, install insulation on the cold water outlet pipe (follow all applicable state and local energy and building

codes).

• To prevent the connected pipe from freezing during winter season, install the drain valve at the bottom of the pipe system.

Water Pump Control

If the water pumps do not operate for an extended period, internal corrosion is more likely.

Water Quality Management

Impurities in the water can influence chiller performance and life expectancy. The water must be tested and treated using a local water treat-

ment professional, and water quality must not fall below the standards listed in the table.

WATER PIPE INSTALLATION / PUMP CONTROL /

QUALITY MANAGEMENT