Action

Yes

No

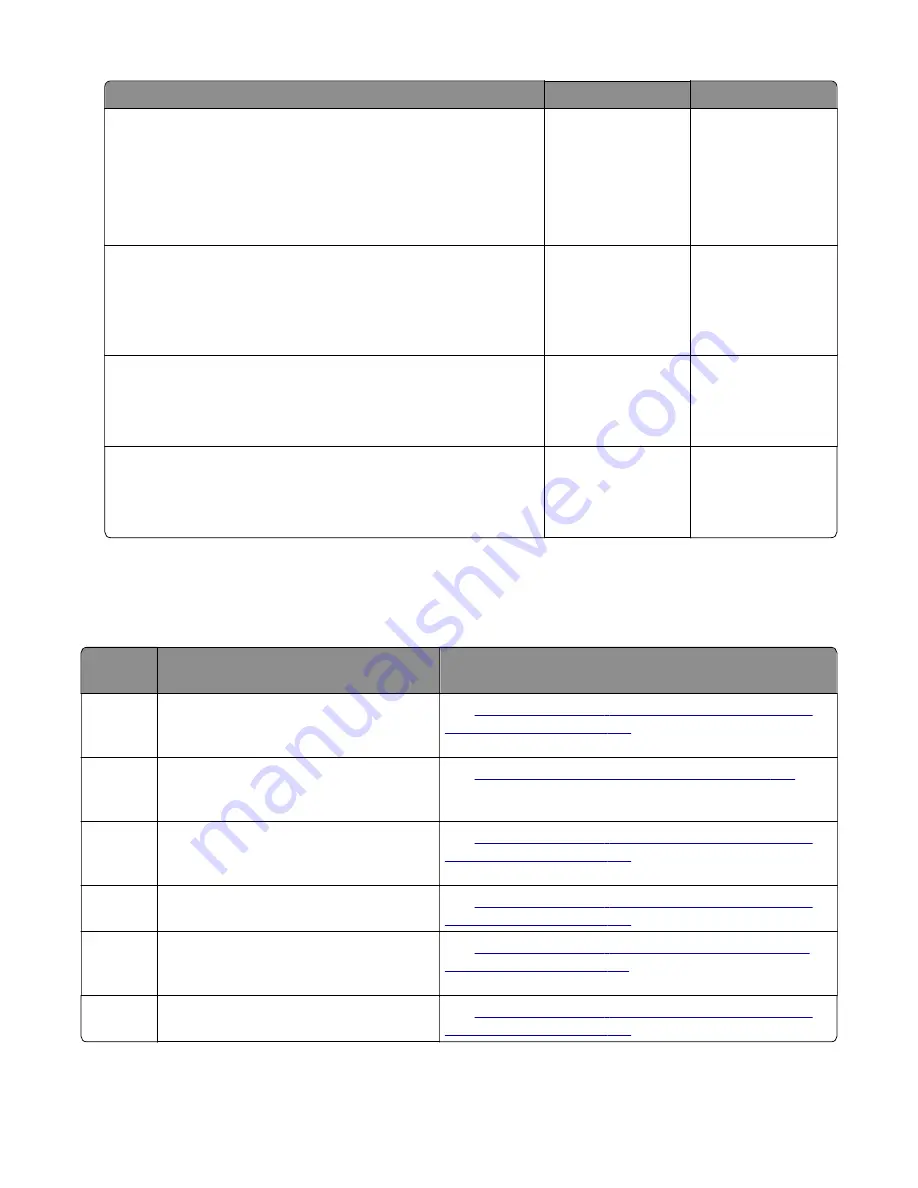

Step 8

a

Enter the Diagnostics menu, and then navigate to:

Printer diagnostics & adjustments

>

Motor tests

>

Deskew

b

Touch

Start

.

Does the motor run?

Go to step 11.

Go to step 9.

Step 9

Check the motor cable for proper connection, and then reseat if

necessary.

Does the problem remain?

Go to step 10.

The problem is

solved.

Step 10

Replace the motor.

Does the problem remain?

Go to step 11.

The problem is

solved.

Step 11

Perform a print job.

Does the problem remain?

Contact the next

level of support.

The problem is

solved.

240 paper jams

240 paper jam messages

Error

code

Description

Action

240.05

Paper fed from the MPF cleared the

sensor (MPF/pass-through) later than

expected.

See

“Sensor (MPF/pass

‑

through): Paper failed to clear

service check” on page 187

.

240.06

Paper fed from the MPF was picked but it

never arrived at the sensor (MPF/pass-

through).

See

“MPF failed to pick service check” on page 189

.

240.07

Paper fed from the MPF cleared the

sensor (MPF/pass-through) later than

expected.

See

“Sensor (MPF/pass

‑

through): Paper failed to clear

service check” on page 187

.

240.25

Paper fed from tray 2 cleared the sensor

(MPF/pass-through) later than expected.

See

“Sensor (MPF/pass

‑

through): Paper failed to clear

service check” on page 187

.

240.26

Paper fed from tray 2 was picked but it

never arrived at the sensor (MPF/pass-

through).

See

“Sensor (MPF/pass

‑

through): Tray 2 failed to pick

service check” on page 191

.

240.27

Paper fed from tray 2 cleared the sensor

(MPF/pass-through) later than expected.

See

“Sensor (MPF/pass

‑

through): Paper failed to clear

service check” on page 187

.

7564

Diagnostic information

178

Summary of Contents for XC8155

Page 22: ...7564 Table of contents 22 ...

Page 101: ...Staple jam in door G 1 Open door C 2 Open door G 7564 Diagnostic information 101 ...

Page 103: ...3 5 Close the staple guard 7564 Diagnostic information 103 ...

Page 106: ... Area J1 Areas J3 and J4 Areas J5 and J6 3 Close door J 7564 Diagnostic information 106 ...

Page 630: ...5 From the rear remove the screw B A B A 7564 Repair information 630 ...

Page 647: ...2 Open door A 3 Remove the waste toner bottle 7564 Repair information 647 ...

Page 653: ...2 Open door A 3 Remove the waste toner bottle 4 Open door A1 7564 Repair information 653 ...

Page 654: ...5 Remove the transfer belt Pick roller removal 1 Remove the tray 7564 Repair information 654 ...

Page 656: ...2 Remove the separator pad Door rod cover removal 1 Remove tray 1 7564 Repair information 656 ...

Page 660: ...6 Remove the fan D D 7564 Repair information 660 ...

Page 674: ...A B 3 Remove the HVPS 7564 Repair information 674 ...

Page 676: ...3 Remove the SIM 7564 Repair information 676 ...

Page 682: ...7 Remove the five screws A A 7564 Repair information 682 ...

Page 699: ...12 Remove the two screws A from the appropriate contact B A B 7564 Repair information 699 ...

Page 706: ...A 8 Remove the ground screw B from the front column B 7564 Repair information 706 ...

Page 719: ...5 Remove the ten screws C securing the motor ADF C 7564 Repair information 719 ...

Page 773: ...4 Remove the two screws A and then remove the motor A 7564 Repair information 773 ...

Page 778: ...3 Remove the bracket 7564 Repair information 778 ...

Page 779: ...4 Move the actuator away and then behind the sensor 7564 Repair information 779 ...

Page 782: ...2 Remove the four screws A A 7564 Repair information 782 ...

Page 792: ...5 Remove the four screws A A A 7564 Repair information 792 ...

Page 793: ...A 6 Push the plate and then pull the assembly to remove 1 2 7564 Repair information 793 ...

Page 847: ...9 Remove the two screws B B 10 Disconnect the cable C C 7564 Repair information 847 ...

Page 849: ...13 Pry the retainer clockwise to unlock and then loosen it 2 1 7564 Repair information 849 ...

Page 856: ...1 2 13 Remove the cam gear assembly 7564 Repair information 856 ...

Page 857: ...14 Pry the retainer clockwise to unlock and then loosen it 2 1 7564 Repair information 857 ...

Page 858: ...15 Release and then remove the bracket from the frames 2 1 3 4 7564 Repair information 858 ...

Page 880: ...3 Remove the two screws A A 4 Remove the motor 7564 Repair information 880 ...

Page 887: ...A B B A 7564 Repair information 887 ...

Page 890: ...7 Remove the four screws E E E E 7564 Repair information 890 ...

Page 893: ...7 Remove the two screws A and then remove the retainer B A B 7564 Repair information 893 ...

Page 900: ...8 Remove the 10 screws C C C 7564 Repair information 900 ...

Page 901: ...9 Remove the four screws D and then set aside the HPT lock D D D 7564 Repair information 901 ...

Page 904: ...10 Remove the two screws A and then remove the retainer B A B 7564 Repair information 904 ...

Page 905: ...11 Remove the 10 screws C C C 7564 Repair information 905 ...

Page 906: ...12 Remove the four screws D D D D 7564 Repair information 906 ...

Page 908: ...16 Remove the roller G G 7564 Repair information 908 ...

Page 913: ...2 Open the hinges and then remove the door 7564 Repair information 913 ...

Page 918: ...Note The latches engage with the holes A on the frame A A 1 3 2 7564 Repair information 918 ...

Page 929: ...5 Remove the two screws C and then remove the cover C 7564 Repair information 929 ...

Page 948: ...5 Remove the two screws A and then open the cage A 7564 Repair information 948 ...

Page 952: ...5 Remove the two screws A and then open the cage A 7564 Repair information 952 ...

Page 957: ...7 Release the bracket from the carriage 7564 Repair information 957 ...

Page 968: ...5 Remove the two screws A and then open the cage A 7564 Repair information 968 ...

Page 970: ...5 Remove the two screws A and then open the cage A 7564 Repair information 970 ...

Page 972: ...5 Remove the two screws A and then open the cage A 7564 Repair information 972 ...

Page 974: ...5 Remove the two screws A and then open the cage A 7564 Repair information 974 ...

Page 976: ...5 Remove the two screws A and then open the cage A 7564 Repair information 976 ...

Page 979: ...5 Remove the two screws A and then open the cage A 7564 Repair information 979 ...

Page 983: ...5 Remove the two screws A and then open the cage A 7564 Repair information 983 ...

Page 987: ...5 Remove the two screws A and then open the cage A 7564 Repair information 987 ...

Page 991: ...6 Remove the two screws A and then open the cage A 7564 Repair information 991 ...

Page 993: ...8 Remove the four screws C and then pull the bracket C 7564 Repair information 993 ...

Page 995: ...5 Remove the two screws A and then open the cage A 7564 Repair information 995 ...

Page 997: ...5 Remove the two screws A and then open the cage A 7564 Repair information 997 ...

Page 1002: ...E D F 7564 Repair information 1002 ...

Page 1009: ...5 Remove the two screws A and then open the cage A 7564 Repair information 1009 ...

Page 1017: ...B C 7564 Repair information 1017 ...

Page 1023: ...20 Using a Torx screwdriver remove the three screws E E D 7564 Repair information 1023 ...

Page 1028: ...19 Disconnect the two cables J J 20 Remove the screw K K 7564 Repair information 1028 ...

Page 1030: ...23 Pull the shaft to the front and then lift it 1 2 7564 Repair information 1030 ...

Page 1039: ...13 Remove the two screws A and then open the cage A 7564 Repair information 1039 ...

Page 1044: ...12 Remove the two screws A and then open the cage A 7564 Repair information 1044 ...

Page 1047: ...F E E 16 Remove the sensor transmitter 7564 Repair information 1047 ...

Page 1059: ...18 Unhook the spring A A 7564 Repair information 1059 ...

Page 1066: ...A A 7564 Repair information 1066 ...

Page 1070: ...14 Remove the E clip D and then remove the bushing D 7564 Repair information 1070 ...

Page 1075: ...16 Remove the E clip D and then remove the bushing D 7564 Repair information 1075 ...

Page 1080: ...19 Remove the E clip D and then remove the bushing D 7564 Repair information 1080 ...

Page 1083: ...25 Pry the bracket to release and then pull it 7564 Repair information 1083 ...

Page 1092: ...B A Installation note Route the cables as shown 7564 Repair information 1092 ...

Page 1093: ...3 Remove the two screws C C 4 Remove the two screws D D 7564 Repair information 1093 ...

Page 1097: ...5 Remove the E clip A from the appropriate roller A A 7564 Repair information 1097 ...

Page 1098: ...6 Remove the E clip B B B 7 Remove the roller Upper roller 1 2 7564 Repair information 1098 ...

Page 1103: ...10 Remove the four screws D D 11 Remove the four screws E E 7564 Repair information 1103 ...

Page 1110: ...10 Remove the four screws D D 11 Remove the four screws E E 7564 Repair information 1110 ...

Page 1111: ...12 Lift the front end of the plate and then remove the plate 7564 Repair information 1111 ...

Page 1112: ...13 Remove the screw F and then loosen the two screws G G F 7564 Repair information 1112 ...

Page 1117: ...16 Remove the five screws E E 7564 Repair information 1117 ...

Page 1122: ...c Align the locating pins C and screw holes D C D 7564 Repair information 1122 ...

Page 1129: ...C D C B 7564 Repair information 1129 ...

Page 1138: ...3 Remove the screw C and then remove the sensor A B C 7564 Repair information 1138 ...

Page 1141: ...Installation notes a Route the cables properly on the rear side 7564 Repair information 1141 ...

Page 1150: ...4 Remove the three screws A A 7564 Repair information 1150 ...

Page 1154: ...C D 7564 Repair information 1154 ...

Page 1161: ...B A B 3 Remove the E clip C C 7564 Repair information 1161 ...

Page 1166: ...G F 7564 Repair information 1166 ...

Page 1178: ...6 Remove the two screws C and then remove the ground screw D D C 7564 Repair information 1178 ...

Page 1192: ...5 Remove the two screws C C 7564 Repair information 1192 ...

Page 1194: ...4 Remove the two E clips A and then remove the handles A 7564 Repair information 1194 ...

Page 1198: ...3 Remove the two E clips A and then remove the handles A 7564 Repair information 1198 ...

Page 1212: ...7564 Repair information 1212 ...

Page 1235: ...10 Remove the eight E clips C and then remove the gears C C B C 7564 Repair information 1235 ...

Page 1236: ...7564 1236 ...

Page 1260: ...7564 1260 ...

Page 1265: ...3 Insert the hole punch box 4 Close door J 7564 Maintenance 1265 ...

Page 1267: ...Assembly 1 Covers 1 3 4 5 6 7 1 10 11 9 8 2 12 7564 Parts catalog 1267 ...

Page 1269: ...Assembly 2 Covers 2 2 1 3 5 6 4 10 9 8 13 12 7 11 7564 Parts catalog 1269 ...

Page 1271: ...Assembly 3 Covers 3 1 2 3 5 4 7 12 11 10 9 6 6 8 7564 Parts catalog 1271 ...

Page 1273: ...Assembly 4 Control panel 3 4 2 5 6 7 8 1 7564 Parts catalog 1273 ...

Page 1275: ...Assembly 5 Duplex 1 2 3 9 4 6 8 5 11 10 12 7 7564 Parts catalog 1275 ...

Page 1279: ...Assembly 7 Feeder 1 3 4 5 6 7 9 8 2 7564 Parts catalog 1279 ...

Page 1281: ...Assembly 8 Frame 6 1 2 4 3 5 7564 Parts catalog 1281 ...

Page 1283: ...Assembly 9 Fuser 7564 Parts catalog 1283 ...

Page 1285: ...Assembly 10 Electronics Front 3 1 6 2 5 4 8 7 7564 Parts catalog 1285 ...

Page 1287: ...Assembly 11 Electronics Rear 3 4 5 6 9 8 1 2 7 7564 Parts catalog 1287 ...

Page 1289: ...Assembly 12 Registration 1 3 5 4 6 11 2 7 8 9 10 7564 Parts catalog 1289 ...

Page 1291: ...Assembly 13 Motors 1 2 7 5 6 4 3 7564 Parts catalog 1291 ...

Page 1293: ...Assembly 14 Printhead 2 3 5 7 8 10 4 1 6 9 7564 Parts catalog 1293 ...

Page 1295: ...Assembly 15 Toner supply 10 3 5 1 2 6 4 4 7 8 9 11 11 11 4 7564 Parts catalog 1295 ...

Page 1297: ...Assembly 16 Redrive 1 3 2 7564 Parts catalog 1297 ...

Page 1299: ...Assembly 17 Transfer Front 1 2 3 4 5 6 5 8 9 10 11 11 7 12 7564 Parts catalog 1299 ...

Page 1301: ...Assembly 18 Transfer Rear 1 2 3 4 4 4 4 5 7564 Parts catalog 1301 ...

Page 1303: ...Assembly 19 ADF 1 7564 Parts catalog 1303 ...

Page 1305: ...Assembly 20 ADF 2 7564 Parts catalog 1305 ...

Page 1307: ...Assembly 21 ADF 3 7564 Parts catalog 1307 ...

Page 1309: ...Assembly 22 ADF 4 7564 Parts catalog 1309 ...

Page 1311: ...Assembly 23 ADF 5 7564 Parts catalog 1311 ...

Page 1313: ...Assembly 24 ADF 6 7564 Parts catalog 1313 ...

Page 1315: ...Assembly 25 Flatbed scanner 1 7564 Parts catalog 1315 ...

Page 1317: ...Assembly 26 Flatbed scanner 2 3 4 5 6 7564 Parts catalog 1317 ...

Page 1319: ...Assembly 27 Flatbed scanner 3 1 2 5 6 7 3 4 7564 Parts catalog 1319 ...

Page 1321: ...Assembly 28 550 sheet tray 1 2 7564 Parts catalog 1321 ...

Page 1323: ...Assembly 29 550 sheet tray Rear 7564 Parts catalog 1323 ...

Page 1325: ...Assembly 30 550 sheet tray Front 9 2 2 10 11 5 7 8 3 4 6 1 12 7564 Parts catalog 1325 ...

Page 1327: ...Assembly 31 2200 sheet tray 1 2 3 4 7564 Parts catalog 1327 ...

Page 1329: ...Assembly 32 2200 sheet tray Front 1 7 3 4 5 6 2 9 1 8 7564 Parts catalog 1329 ...

Page 1331: ...Assembly 33 2200 sheet tray Rear 7564 Parts catalog 1331 ...

Page 1333: ...Assembly 34 Caster base 2 3 3 3 2 1 7564 Parts catalog 1333 ...

Page 1338: ...7564 Parts catalog 1338 ...

Page 1342: ...7564 Parts catalog 1342 ...

Page 1343: ...Assembly 39 Staple finisher option 1 7564 Parts catalog 1343 ...

Page 1345: ...Assembly 40 Staple finisher Covers 8 3 4 5 1 2 1 1 6 7 7564 Parts catalog 1345 ...

Page 1347: ...Assembly 41 Staple finisher Front 4 3 2 5 6 7 8 9 10 7564 Parts catalog 1347 ...

Page 1349: ...Assembly 42 Staple finisher Electrical 6 1 2 4 3 5 7564 Parts catalog 1349 ...

Page 1351: ...Assembly 43 Staple finisher Rear 1 2 3 5 6 4 7 7564 Parts catalog 1351 ...

Page 1353: ...Assembly 44 Staple finisher Tamper 1 2 2 3 3 4 5 6 7 8 9 11 10 7564 Parts catalog 1353 ...

Page 1355: ...Assembly 45 Staple finisher Transport 4 5 6 6 7 8 1 3 2 7564 Parts catalog 1355 ...

Page 1357: ...Assembly 46 Staple finisher Bottom 7564 Parts catalog 1357 ...

Page 1359: ...Assembly 47 Mailbox 1 M1 M2 1 7564 Parts catalog 1359 ...

Page 1361: ...Assembly 48 Mailbox 2 7564 Parts catalog 1361 ...

Page 1363: ...Assembly 49 Mailbox 3 7564 Parts catalog 1363 ...

Page 1365: ...Assembly 50 Mailbox 4 1 2 3 4 6 7 8 9 5 7564 Parts catalog 1365 ...

Page 1367: ...Assembly 51 Mailbox 5 7564 Parts catalog 1367 ...

Page 1369: ...Assembly 52 HPT 1 7564 Parts catalog 1369 ...

Page 1371: ...Assembly 53 HPT 2 7564 Parts catalog 1371 ...

Page 1373: ...Assembly 54 HPT 3 7564 Parts catalog 1373 ...

Page 1375: ...Assembly 55 HPT 4 7564 Parts catalog 1375 ...

Page 1377: ...Assembly 56 HPT 5 7564 Parts catalog 1377 ...

Page 1379: ...Assembly 57 MSHPF covers 1 1 2 3 4 5 6 7 8 15 9 10 12 11 13 14 7564 Parts catalog 1379 ...

Page 1381: ...Assembly 58 MSHPF covers 2 7564 Parts catalog 1381 ...

Page 1383: ...Assembly 59 MSHPF electronics 2 4 6 3 5 7 8 1 7564 Parts catalog 1383 ...

Page 1385: ...Assembly 60 MSHPF mid transport drive 2 1 3 8 12 7 6 5 10 13 11 9 4 7564 Parts catalog 1385 ...

Page 1387: ...Assembly 61 MSHPF mid transport paper path 6 1 4 3 1 2 9 5 7 8 7564 Parts catalog 1387 ...

Page 1389: ...Assembly 62 MSHPF offset drive 2 1 3 4 7564 Parts catalog 1389 ...

Page 1391: ...Assembly 63 MSHPF standard bin 1 8 7 5 6 3 4 2 1 7564 Parts catalog 1391 ...

Page 1393: ...Assembly 64 MSHPF standard bin 2 4 3 5 7 8 9 6 2 1 7564 Parts catalog 1393 ...

Page 1399: ...Assembly 67 MSHPF staging paper path 1 5 7 8 9 10 3 4 2 6 11 7564 Parts catalog 1399 ...

Page 1403: ...Assembly 69 MSHPF compiler 2 2 3 4 2 5 6 1 7564 Parts catalog 1403 ...

Page 1405: ...Assembly 70 MSHPF tamper 2 1 3 8 4 5 5 6 9 7 7564 Parts catalog 1405 ...

Page 1407: ...Assembly 71 MSHPF carriage transport 10 11 7 8 9 1 2 3 4 5 6 7564 Parts catalog 1407 ...

Page 1409: ...Assembly 72 MSHPF door interlock 1 3 2 7564 Parts catalog 1409 ...

Page 1411: ...Assembly 73 MSHPF stapler bin 1 1 5 4 3 3 2 6 7 8 7564 Parts catalog 1411 ...

Page 1413: ...Assembly 74 MSHPF stapler bin 2 1 2 5 3 4 7564 Parts catalog 1413 ...

Page 1415: ...Assembly 75 MSHPF stapler bin 3 2 8 3 4 7 1 4 5 6 7564 Parts catalog 1415 ...

Page 1417: ...Assembly 76 MSHPF cabinet 3 1 1 3 4 4 5 5 7 7 8 8 2 6 7564 Parts catalog 1417 ...

Page 1420: ...7564 1420 ...

Page 1464: ...Multiple sheets Single sheet thick 7564 Appendix C Theory of operation 1464 ...

Page 1506: ...7564 1506 ...

Page 1520: ...7564 Index 1520 ...

Page 1540: ...7564 Part number index 1540 ...

Page 1560: ...7564 Part name index 1560 ...