2-18

Service Manual

4400-001

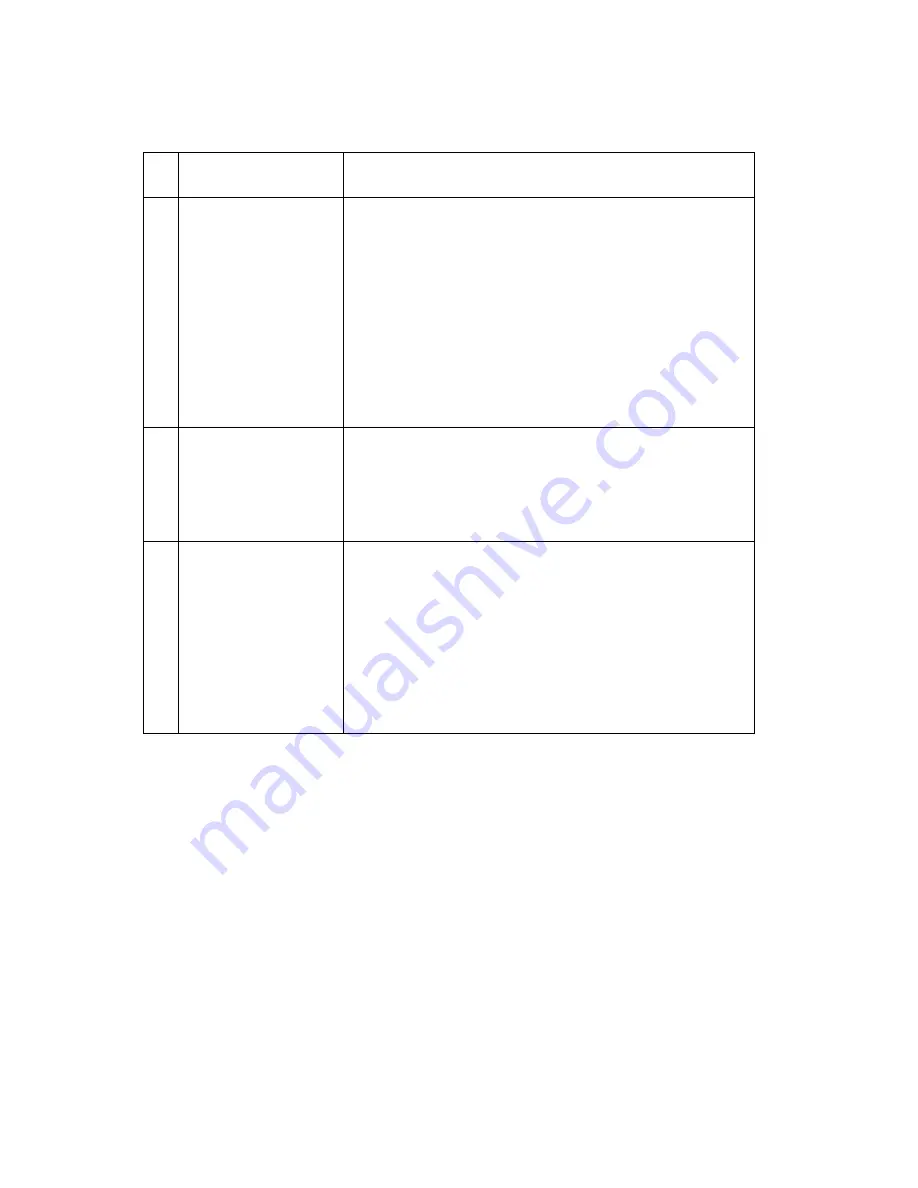

Scan/Copy Quality Service Check

FRU / Function

Action

1

Scanned images

are: faded, or

colors are dull,

blurry or fuzzy.

Images are

slanted or

crooked and the

straight lines in

the image appear

to be jagged or

uneven.

Check the lighter/darker settings to see if it is

correct.

• From the operator panel

• From the Scan & Copy Control Program

Check to see if there is any dust or debris on the

glass lens of the CIS. This may cause a poor

image.

2

Blank copies

If blank copies found, make sure that the original

document is facing down.

Check the print cartridges to see if they need to be

cleaned or replaced.

3

Scanning error

Ensure the USB cable is correctly installed.

Ensure the USB cable is proper for USB

specification, version 1.1.

Start the system after twain driver is reinstalled.

If error still occurs, replace the system board. Go

to the

“System Board Removal” on page 4-21

.

Summary of Contents for X63

Page 9: ...Safety Information ix 4400 001...

Page 16: ...1 6 Service Manual 4400 001...

Page 36: ...2 20 Service Manual 4400 001...

Page 64: ...4 18 Service Manual 4400 001 11 Remove ASF assembly...

Page 72: ...4 26 Service Manual 4400 001...

Page 74: ...5 2 Service Manual 4400 001 Logic Card Units Description P1 System Board P2 Phone Lines...

Page 75: ...Connector Locations 5 3 4400 001 Power Supply Units Description J5 System Board...

Page 76: ...5 4 Service Manual 4400 001...

Page 78: ...6 2 Service Manual 4400 001...

Page 80: ...7 2 Service Manual 4400 001 Assembly 1 Main Assembly...

Page 82: ...7 4 Service Manual 4400 001 Assembly 2 Base Unit...

Page 84: ...7 6 Service Manual 4400 001 Assembly 3 Engine...

Page 86: ...7 8 Service Manual 4400 001...