2-60

Service Manual

5022-

xxx

3

Remove HVPS. Go to

supply (HVPS) removal” on page 4-55

.

Check for continuity between black1 and

black2 on transfer contact assembly. Is

continuity present?

Go to step 4.

Replace transfer contact

assembly. Go to

contact assembly

removal” on page 4-57

4

Replace transfer contact assembly. Go to

“Transfer contact assembly removal” on

page 4-57

. Does error clear?

Problem solved.

Go to step 5.

5

Replace HVPS. Go to

supply (HVPS) removal” on page 4-55

.

Does error clear?

Problem solved.

Replace system card. Go to

“System card removal” on

page 4-47

Step

Questions / actions

Yes

No

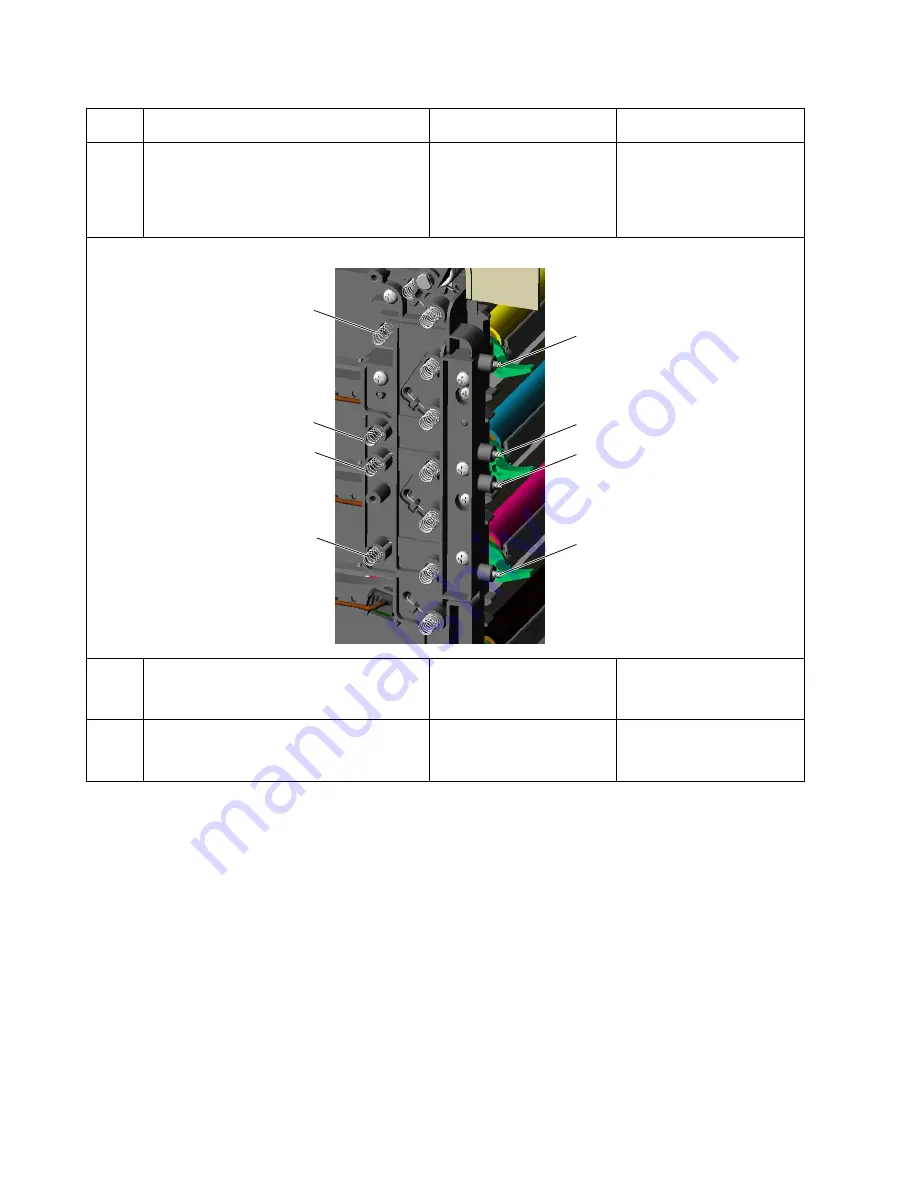

\HOORZ

PDJHQWD

EODFN

\HOORZ

F\DQ

F\DQ

PDJHQWD

EODFN

Summary of Contents for C520 Series

Page 8: ...viii Service Manual 5022 xxx...

Page 13: ...Laser notices xiii 5022 xxx Japanese Laser Notice...

Page 14: ...xiv Service Manual 5022 xxx Korean Laser Notice...

Page 33: ...General information 1 15 5022 xxx...

Page 132: ...2 74 Service Manual 5022 xxx...

Page 202: ...4 48 Service Manual 5022 xxx 5 Remove eight screws C from system card...

Page 222: ...5 2 Service Manual 5022 xxx 7RQHU SDWFK VHQVRU 736 7RQHU OHYHO VHQVRUV...

Page 223: ...Locations and connectors 5 3 5022 xxx Motors...

Page 224: ...5 4 Service Manual 5022 xxx Printer cards...

Page 226: ...5 6 Service Manual 5022 xxx Parallel system card Legend Jxx connector Fx fuse...

Page 227: ...Locations and connectors 5 7 5022 xxx Wiring diagrams See back of manual...

Page 228: ...5 8 Service Manual 5022 xxx...

Page 230: ...6 2 Service Manual 5022 xxx...

Page 232: ...7 2 Service Manual 5022 xxx Assembly 1 CRUs 5HDU 9LHZ...

Page 234: ...7 4 Service Manual 5022 xxx Assembly 2 Covers...

Page 236: ...7 6 Service Manual 5022 xxx Assembly 3 Front...

Page 238: ...7 8 Service Manual 5022 xxx Assembly 4 Right...

Page 240: ...7 10 Service Manual 5022 xxx Assembly 5 Rear...

Page 242: ...7 12 Service Manual 5022 xxx Assembly 6 Left...

Page 244: ...7 14 Service Manual 5022 xxx Assembly 7 Top...

Page 248: ...7 18 Service Manual 5022 xxx Assembly 9 Cable Parts Packet...

Page 254: ...I 4 Service Manual 5022 xxx...