Bearing Lubrication

Below is a listing of approved lubrication.

The grease used should meet the requirements as shown in the chart above. The following amounts

of grease should be used:

•

4 ounces to completely exchange the grease throughout the hub

•

1 1/2 - 3 ounces every (3) months or 1000 miles thereafter or as use requires

l

ubriCaTiOn

S

peCifiCaTiOnS

Grease

Dropping Point

230°C (446°F) Minimum

Viscosity Index

80 Mini-

mum

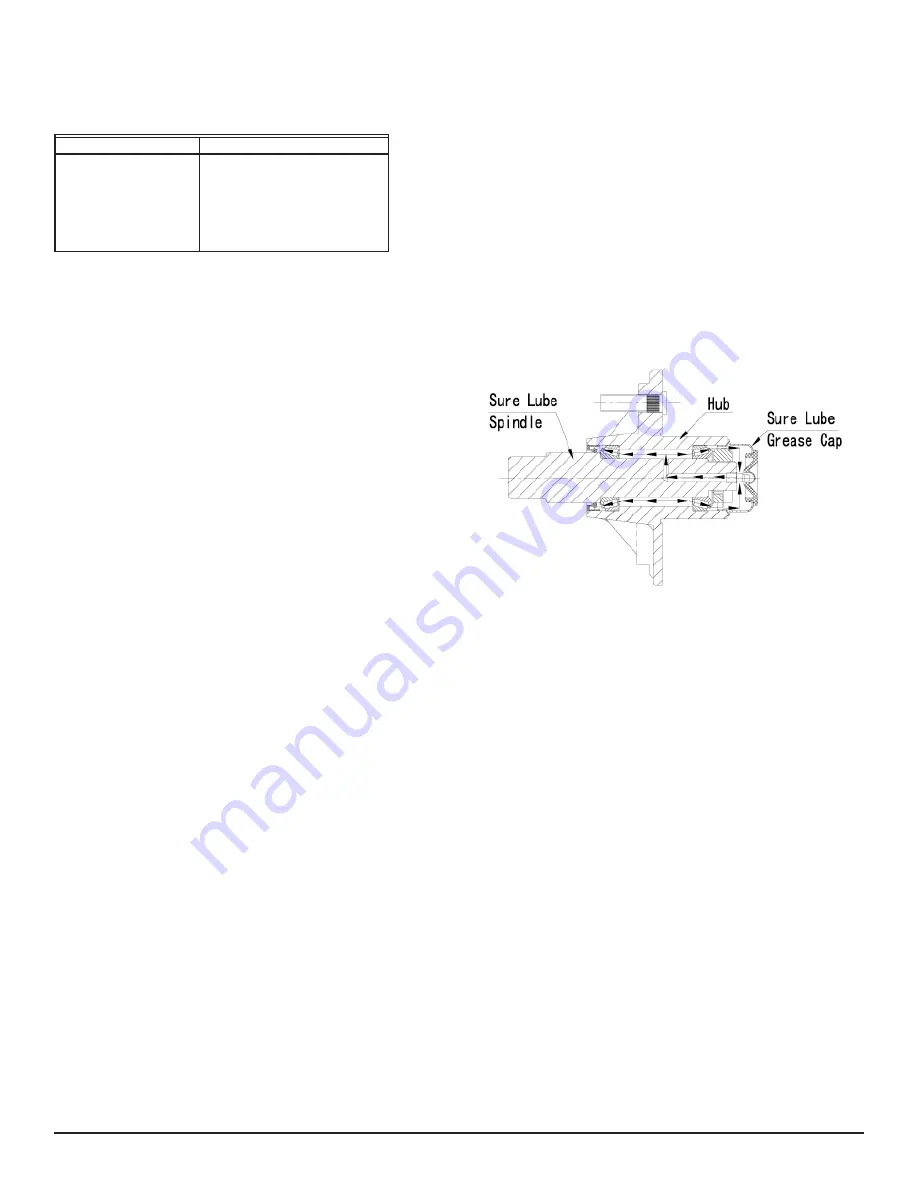

Bearing Adjustment, Hub Installation, and Lubrication

Bearing adjustment is a very important part of achieving maximum bearing life and trouble-free service. Most bearing fail-

ures can be attributed to improper bearing adjustment, normally due to the bearings being adjusted too tight.

Once all of the necessary inspections have been performed and the units have been properly lubricated, the following

procedure should be used for reinstallation of the hubs:

1. Place the lubricated unit onto the same spindle from which it was removed. Make sure all of the components are

reinstalled as they were removed.

2. Place the flat washer onto the spindle followed by the bend-leg washer, followed by the castle nut.

3. Finger-tighten the castle nut by hand without moving the hub.

4. Bend the legs of the bend-leg washer to the channel of the castle nut to ensure the castle nut will not back off.

5. The castle nut should be free to move with your fingers with only the bend-leg washer holding it in place and the

hub should not have noticeable movement when pulled back and forth.

6. After assembling the hub, the grease is pumped through the hub via the grease zert in the end of the grease cap,

then through the hole in the spindle to the space between the two bearings. The final step is to reinstall the dust

cap.

Page 5 of 21