4

.

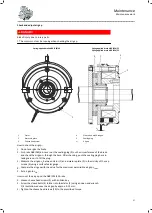

Measure the air gap s

L

between stator (1) and armature plate (2) in the vicinity of the cap

screws (3) using a surface feeler gauge.

NOTICE

▶

With the holding brake HBR and application brake ABR (motor protection class IP65/66) the

air gap cannot be adjusted! If the air gap s

L,max

is reached, the brakes must be replaced.

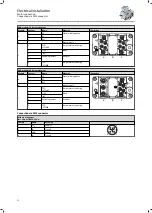

Holding brake HBR

Brake

Braking torque is static

Air gap

s

L,max

s

L,N

Nm

mm

mm

HBR 06

4

0.6

0.2 ±0.1

HBR 08

8

0.6

HBR 10

16

0.7

0.3 ±0.1

23

0.5

HBR 12

32

0.8

HBR 14

60

0.8

HBR 16

80

0.9

HBR 18

150

0.6

0.4

+0.10

-0.05

Application brake ABR, protection class IP54/55

Brake

Tightening torque

Air gap

s

L,max

s

L,N

Service brake

Holding brake

Nm

mm

mm

ABR 06

3.0

0.50

0.30

0.2

+0.10

-0.05

ABR 08

5.9

ABR 10

10.1

ABR 12

10.1

0.75

0.45

0.3

+0.10

-0.05

ABR 14

24.6

ABR 16

24.6

ABR 18

24.6

1.00

0.60

0.4

+0.10

-0.05

ABR 20

48.0

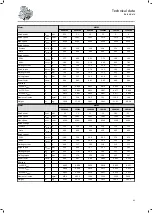

Application brake ABR, protection class IP65/66

Brake

Tightening torque

Air gap

s

L,max

s

L,N

Service brake

Holding brake

Nm

mm

mm

ABR 06

3.0

0.50

0.30

0.2

+0.08

-0.05

ABR 08

5.9

0.50

0.30

0.2

+0.08

-0.05

ABR 10

10.1

0.50

0.30

0.2

+0.13

-0.05

ABR 12

10.1

0.60

0.45

0.3

+0.08

-0.10

ABR 14

24.6

0.75

0.45

0.3 ±0.1

ABR 16

24.6

0.80

0.50

0.3

+0.15

-0.05

ABR 18

24.6

1.0

0.65

0.4

+0.20

-0.10

Maintenance

Maintenance work

38