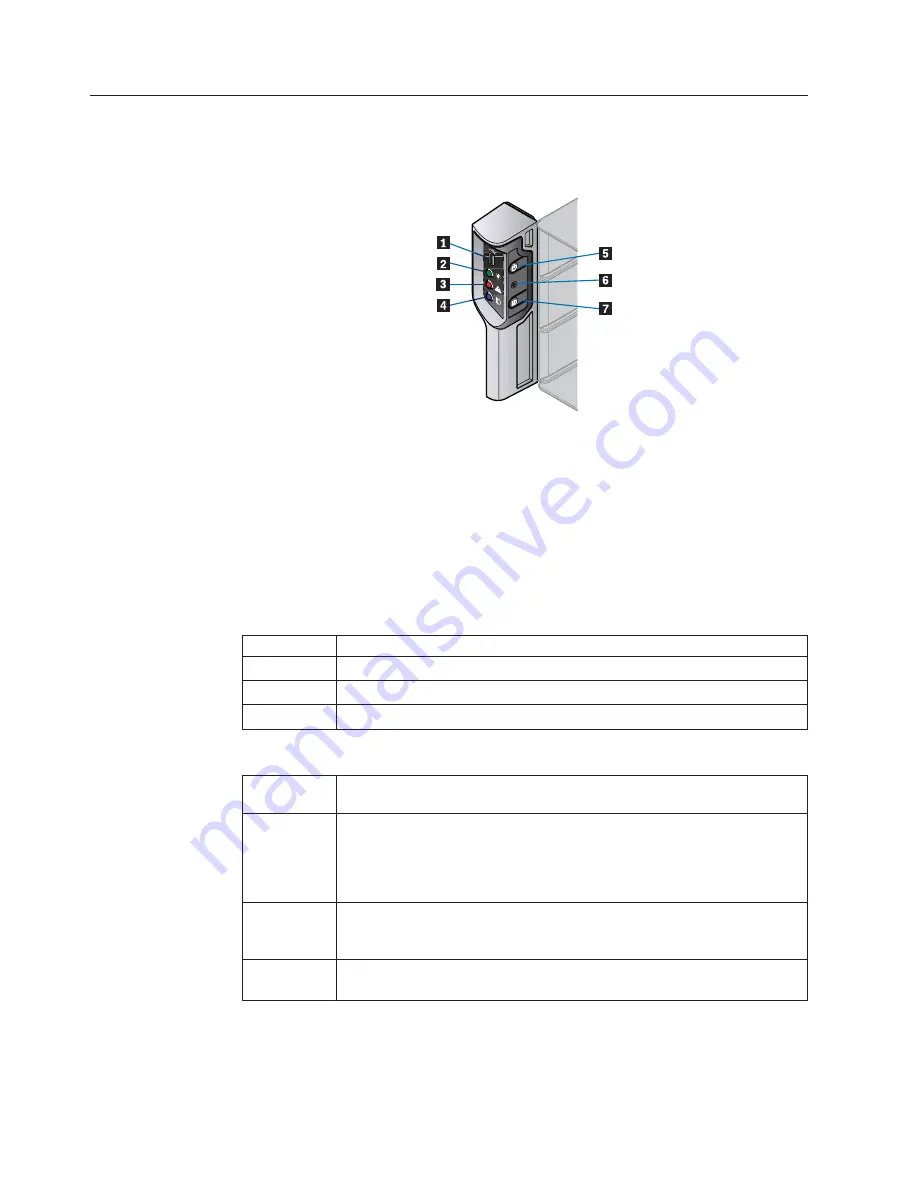

Front

operator's

panel

LEDs

and

switches

The

front

operator’s

panel

LED

fault

and

status

conditions

are

defined

in

Table

4.

Functions

of

the

push-button

switches

are

defined

in

Table

5.

1

USB

port

2

Power

active

LED

3

Unit

fault

LED

4

ID

LED

5

On/off

switch

6

Reset

button

(recessed)

7

ID

LED

activation

switch

Table

4.

Front

operator's

panel

LED

states

LED

Status

Power

active

Constant

green:

good

or

positive

indication

Unit

fault

Constant

amber:

fault

present

Enclosure

ID

Blue:

only

when

activated

Table

5.

Front

operator's

panel

switch

functions

Push-button

switch

Definition

On/Off

Function

of

this

button

is

dependent

on

the

enclosure

status.

Enclosure

connected

to

power

source

but

not

operating.

Press

button

to

activate

and

commence

boot

process.

Enclosure

operating

:

Depress

button

for

<4

seconds

to

turn

off

the

enclosure.

System

reset

Resets

the

enclosure

hardware

and

firmware.

This

button

is

recessed

and

is

activated

with

a

ball-point

pen

or

similar

implement.

Enclosure

ID

Each

press

of

this

button

causes

the

state

of

the

blue

ID

LED

on

the

Front

Operator's

Panel

and

rear

panel

to

change.

Figure

18.

Front

operator’s

panel

components

20

User

Guide

Summary of Contents for Secure Managed Client Storage Array

Page 1: ... Secure Managed Client Storage Array User Guide Machine Type 8332 ...

Page 2: ......

Page 3: ...Secure Managed Client Storage Array User Guide ...

Page 6: ...iv User Guide ...

Page 8: ...vi User Guide ...

Page 10: ...2 User Guide ...

Page 20: ...12 User Guide ...

Page 26: ...18 User Guide ...

Page 40: ...32 User Guide ...

Page 43: ......

Page 44: ...Part Number 45K1342 Printed in USA 1P P N 45K1342 ...