9

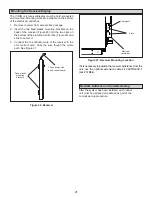

Refrigerant Piping Connections

IMPORTANT

The compressor in the unit this air handler is matched

with contains PVE oil (Polyvinyl ether). PVE oil is

formulated for hydrofluorocarbon (HFC) refrigerants,

such as R410A, which this system contains. While it may

have some miscibility properties with mineral-based oil

and POE oil (Polyolester), it is not recommended to mix

PVE oil with any other type of refrigerant oil.

Refrigerant leaks are unlikely; however, if a refrigerant

leak occurs, open a door or windows to dilute the

refrigerant in the room. Turn off the unit and all other

appliances that may cause a spark. Call a licensed

professional HVAC technician (or equivalent) to repair

the leak.

Use only R410A refrigerant to charge this system. Use

of other refrigerant or gas will damage the equipment.

Do not allow air or other contaminants to enter system

during installation of refrigerant piping. Contaminants

will result in lower system capacity and abnormally high

operating pressures and may result in system failure or

explosion.

Insulate all refrigerant piping.

Refrigerant pipes may be very hot during unit operation.

Do not allow contact between wiring and bare copper

pipes.

After refrigerant piping connections have been

completed, check the system for leaks per

commissioning instructions.

WARNING

WARNING

Danger of fire. Bleeding the refrigerant

charge from only the high side may result

in pressurization of the low side shell and

suction tubing. Application of a brazing torch

to a pressurized system may result in ignition

of the refrigerant and oil mixture. Check the

high and low pressures before applying heat.

CAUTION

Brazing alloys and flux contain materials which are

hazardous to your health.

Avoid breathing vapors or fumes from brazing operations.

Perform operations only in well-ventilated areas.

Wear gloves and protective goggles or face shield to

protect against burns.

Wash hands with soap and water after handling brazing

alloys and flux.

IMPORTANT

Refrigerant lines must be clean, dry, refrigerant-grade

copper lines. Air handler coils should be installed

only with specified line sizes for approved system

combinations.

Handle refrigerant lines gently during the installation

process. Sharp bends or kinks in the lines will cause

restrictions.

IMPORTANT

Only use brazing rods/sticks which are suitable/

recommended for air conditioning pipework installations

- Do Not Use Soft Solder.

CAUTION

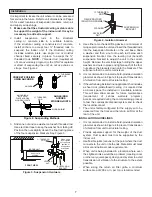

Purge low pressure nitrogen [1 to 2 psig (6.0 to 12.8

kPA)] through the refrigerant piping during brazing. This

will help to prevent oxidation and the introduction of

moisture into a system.

To prevent the build-up of high levels of nitrogen when

purging be sure it is done in a well ventilated area.