Venting Requirements

All Clearances and Instructions Listed By Vent Manufacturer Must Be Followed.

IT IS RECOMMENDED THAT ONLY AN AUTHORIZED DEALER INSTALL YOUR PELLET STOVE. THE

FOLLOWING INSTALLATION REQUIREMENTS MUST BE FOLLOWED

TO

ENSURE CONFORMITY

WITH BOTH THE SAFETY LISTING

OF

THE APPLIANCE AND LOCAL BUILDING CODES.

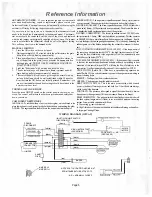

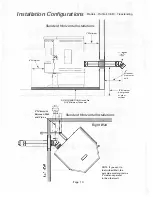

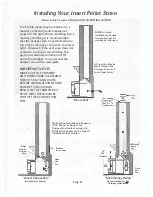

Freestanding Models - Pipe and Venting

There are several options for installing and venting of

these pellet appliances. Refer to clearances before in

stalling your stove.

The Whitfield and Tradition brand pellet appliances are

approved for use with the following vent sizes; Approved

Sizes: 3"/75mm (standard) or 4"/100mm. See page 17 -

for determining correct size vent.

The most desirable installation is to install a "Tee" on

the back of the stove and installing pipe up through the

ceiling, then terminating above the roofline. Position the

appliance far enough away from walls to allow adequate

room for servicing.

The required type of pipe is a listed type "PL" (pellet

vent pipe. It is sometimes referred to as "L-Vent pellet

vent"), which conforms to UL standard 641. The pipe

should be attached (and sealed) to the flue outlet collar

on the back of the stove. Use a 3"/75mm to 4"/100mm

adapter or a 3"/75mm to 4"/100mm Tee in order to run

4"/100mm pipe.

Choose the appliance location with the least amount of in

terference with the house framing, plumbing, wiring, etc.

Do not connect this appliance to a chimney flue

servicing another appliance.

Do not install a flue damper in the exhaust venting

system of this appliance.

Maintain clearances in accordance with NFPA 211.

WARNING: DO NOT USE CLASS B VENTING IN

TENDED FOR GAS APPLIANCES AS A CHIMNEY OR

CONNECTOR PIPE ON A PELLET FIRED APPLI

ANCE.

Follow pipe manufacturers installation '-i�tructions for

precautions required for passing pipe through a com

bustible wall or ceiling (i.e. use an approved thimble).

Connect the pellet vent pipe or the "Tee" to the flue col

lar using a minimum of three screws. Use an RTV sili

cone with a rating of at least 570

°

F (969

°

C), or lnteram

to provide a complete seal at the flue collar and on all

joints.

Total Offsets in venting system should not exceed 270

°

total in direction change.

Horizontal Run Allowed: Maximum total is not to exceed

10 feet (3.1 meters).

Horizontal run of pipe should have 1/4" (7 mm) rise

per foot.

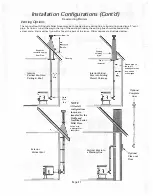

Ninety-degree elbows accumulate fly ash and soot

which reduces the exhaust flow and performance of the

stove. Horizontal runs of pipe will collect fly ash as well.

It is recommended that a single or double clean-out

"tee" be installed at every 90-degree turn. Installation of

a clean-out tee is recommended to permit periodic

cleaning of both the horizontal and vertical runs of pipe.

Pellet vent pipe requires 3"/75mm clearance from out

side of pipe (all diameters: 3"/75mm & 4"/100mm).

A support bracket must be installed every 4'/1.2m of

pellet vent pipe on the exterior.

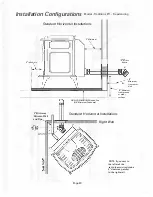

Connection to Masonry Chimney Through a Wall

Be sure to verify the construction of a masonry chimney,

as many have combustible framing.

The use of single wall flex or rigid 24-gage stainless

steel pipe as a liner is approved.

Connection to an Existing Class A Chimney

A chimney adapter can be used to make the connection

from 3"/75mm or 4"/100mm pellet vent pipe to existing

UL chimney system. Verify with the pipe manufacturer

that your pipe brands will interconnect. The use of single

wall flex or rigid pipe (24 gage stainless steel) as a liner

is approved.

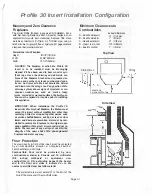

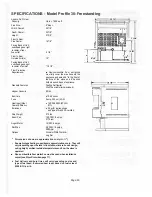

Fireplace Insert Model Profile 30 - Venting

Requirements

Masonry and zero clearance fireplace installations re

quire a full liner system. The 3"/75mm or 4"/100mm pipe

is required. When using single wall pipe, flex or rigid

liner, you must use a section of pellet vent pipe on the

top of the chimney where the pipe is exposed to the

elements. Single wall, flex, or rigid liner is not designed

for exposure to the elements. Do not insulate around

liner or use a seal off plate where the liner passes

through the damper (Air must communicate freely, with

chimney area).

I' Adjustable

Section

Pellet

Vent ----=�r'--�

3" or 4" -+--..-.

Stainless

Flex

-·----

Chase

Cover

All pipe joints must be sealed. Use an RTV silicone with

a rating of at least 570

°

F (969

°

C), or lnteram to pro

vide a complete seal at the flue collar and on all joints.

Page 15