Page 58

VI-TYPICAL OPERATING CHARACTERISTICS

A-Blower Operation and Adjustment

1 - Blower operation is dependent on thermostat control

system.

2 - Generally, blower operation is set at thermostat subbase

fan switch. With fan switch in ON position, blower oper

ates continuously. With fan switch in AUTO position,

blower cycles with demand or runs continuously while

heating or cooling circuit cycles.

3 - Depending on the type of indoor thermostat, blower and

entire unit will be off when the system switch is in OFF

position.

B-Temperature Rise

Temperature rise for SLP98DFV units depends on unit in

put, blower speed, blower horsepower and static pressure

as marked on the unit rating plate. The blower speed must

be set for unit operation within the range of “TEMP. RISE

°

F” listed on the unit rating plate.

To Measure Temperature Rise:

1 - Place plenum thermometers in the supply and return air

plenums. Locate supply air thermometer in the first hori

zontal run of the plenum where it will not pick up radiant

heat from the heat exchanger.

2 - Set thermostat for heat call. Unit must operate on sec

ond-stage heat.

If using a single-stage thermostat fur

nace must fire at least 10 minutes before switching to

second-stage heat.

3 - After plenum thermometers have reached their highest

and steadiest readings, subtract the two readings. The

difference should be in the range listed on the unit rating

plate. If the temperature is too low, decrease blower

speed. If temperature is too high, first check the firing

rate. Provided the firing rate is acceptable, increase

blower speed to reduce temperature.

C-External Static Pressure

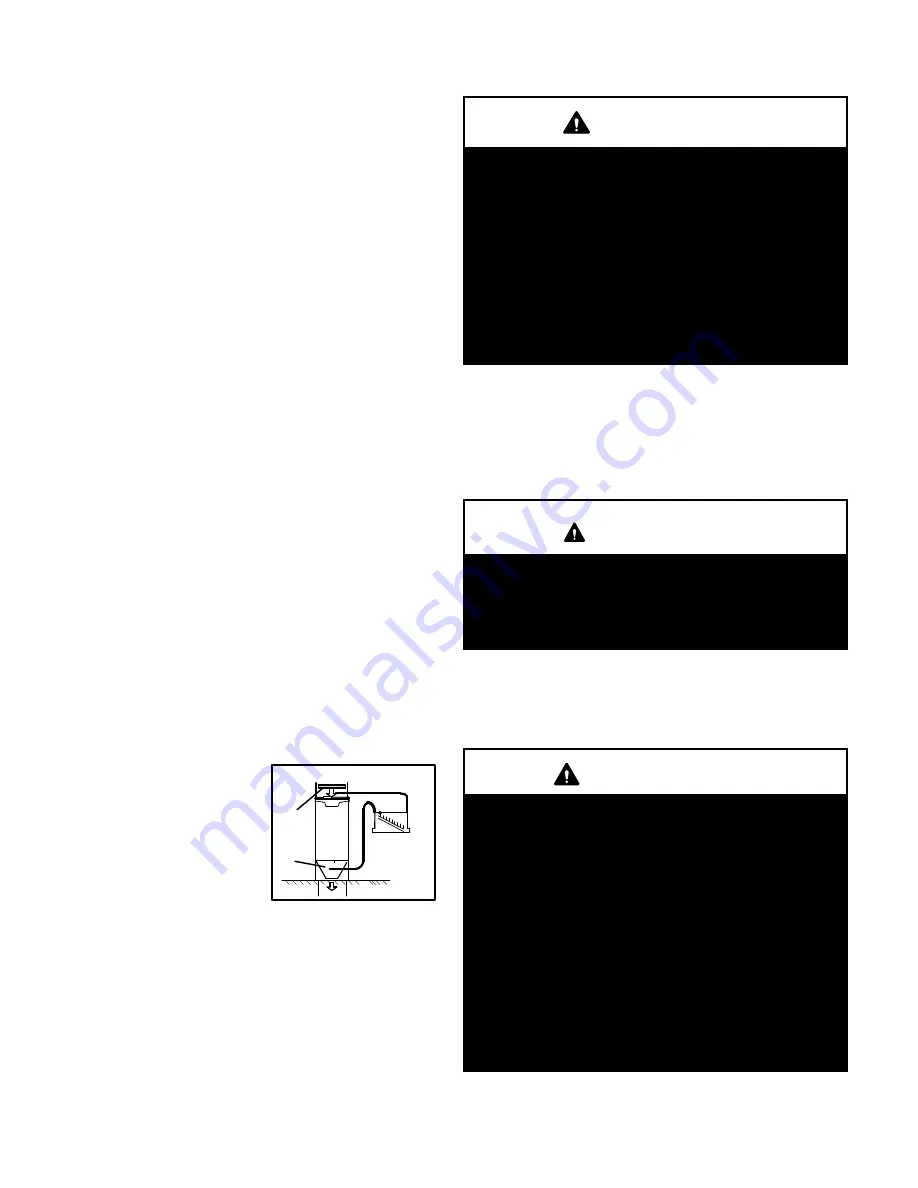

1 - Tap locations shown in figure 50.

2 - Punch a 1/4” diameter hole in

supply and return air ple

nums. Insert manometer

hose flush with inside edge of

hole or insulation. Seal

around the hose with perma

gum. Connect the zero end of

the manometer to the dis

charge (supply) side of the system. On ducted systems,

connect the other end of manometer to the return duct

as above.

3 - With only the blower motor running and the evaporator

coil dry, observe the manometer reading. Adjust blower

motor speed to deliver the air desired according to the

job requirements.

4 - External static pressure drop must not be more than

0.8” W.C. in the heating mode and must not exceed 1.0”

W.C in the cooling mode.

5 - Seal the hole when the check is complete.

VII-MAINTENANCE

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly could result

in dangerous operation, serious injury, death or prop

erty damage.

Improper servicing could result in dangerous opera

tion, serious injury, death, or property damage.

Before servicing, disconnect all electrical power to

furnace.

When servicing controls, label all wires prior to dis

connecting. Take care to reconnect wires correctly.

Verify proper operation after servicing.

At the beginning of each heating season, system should be

checked as follows by a qualified service technician:

Blower

Check the blower wheel for debris and clean if necessary.

The blower motors are prelubricated for extended bearing

life. No further lubrication is needed.

WARNING

The blower access panel must be securely in place

when the blower and burners are operating. Gas

fumes, which could contain carbon monoxide, can be

drawn into living space resulting in personal injury or

death.

Filters

All SLP98DFV filters are installed external to the unit. Fil

ters should be inspected monthly. Clean or replace the fil

ters when necessary to ensure proper furnace operation.

All SLP98DFV units use a 16 x 25 x1 filter.

IMPORTANT

If a highefficiency filter is being installed as part of

this system to ensure better indoor air quality, the fil

ter must be properly sized. Highefficiency filters

have a higher static pressure drop than standardeffi

ciency glass/foam filters. If the pressure drop is too

great, system capacity and performance may be re

duced. The pressure drop may also cause the limit to

trip more frequently during the winter and the indoor

coil to freeze in the summer, resulting in an increase

in the number of service calls.

Before using any filter with this system, check the

specifications provided by the filter manufacturer

against the data given in the appropriate Lennox

Product Specifications bulletin. Additional informa

tion is provided in Service and Application Note

ACC002 (August 2000).

Exhaust and air intake pipes

Check the exhaust and air intake pipes and all connections

for tightness and to make sure there is no blockage.

STATIC PRESSURE TEST

filter

coil