Page 21

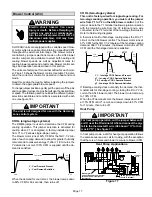

Table 9

Burner Specifications

Unit

Burner

Number

Beckett

Spec. No.

Beckett

Air Tube Part

No.

Input

Rating

BTU/HR

Nozzle Size,

Spray, Angle, &

Pattern

Pump

Pres-

sure

Head

Insertion

Length

Static

Plate

Diameter

SLO183B3/4−101/114V

100591−05

ARM2008

AF46XNHS

101,000

0.65gph X 80° B

140

F3

4−3/4

2−3/4

SLO183B3/4−101/114V

100591−05

ARM2008

AF46XNHS

114,000

*0.65gph X 80° B

140

F3

4−3/4

2−3/4

SLO183B5−135/150V

100591−06

ARM2009

AF46WPHS

135,000

1.00gph x 80°

140

F4

4−3/4

3−3/8

SLO183B5−135/150V

100591−06

ARM2009

AF46WPHS

150,000

*1.00gph X 80° B

140

F4

4−3/4

3−3/8

*Nozzle must be field−installed for conversion to higher heating input.

NOTE − All nozzles are Delavan brand.

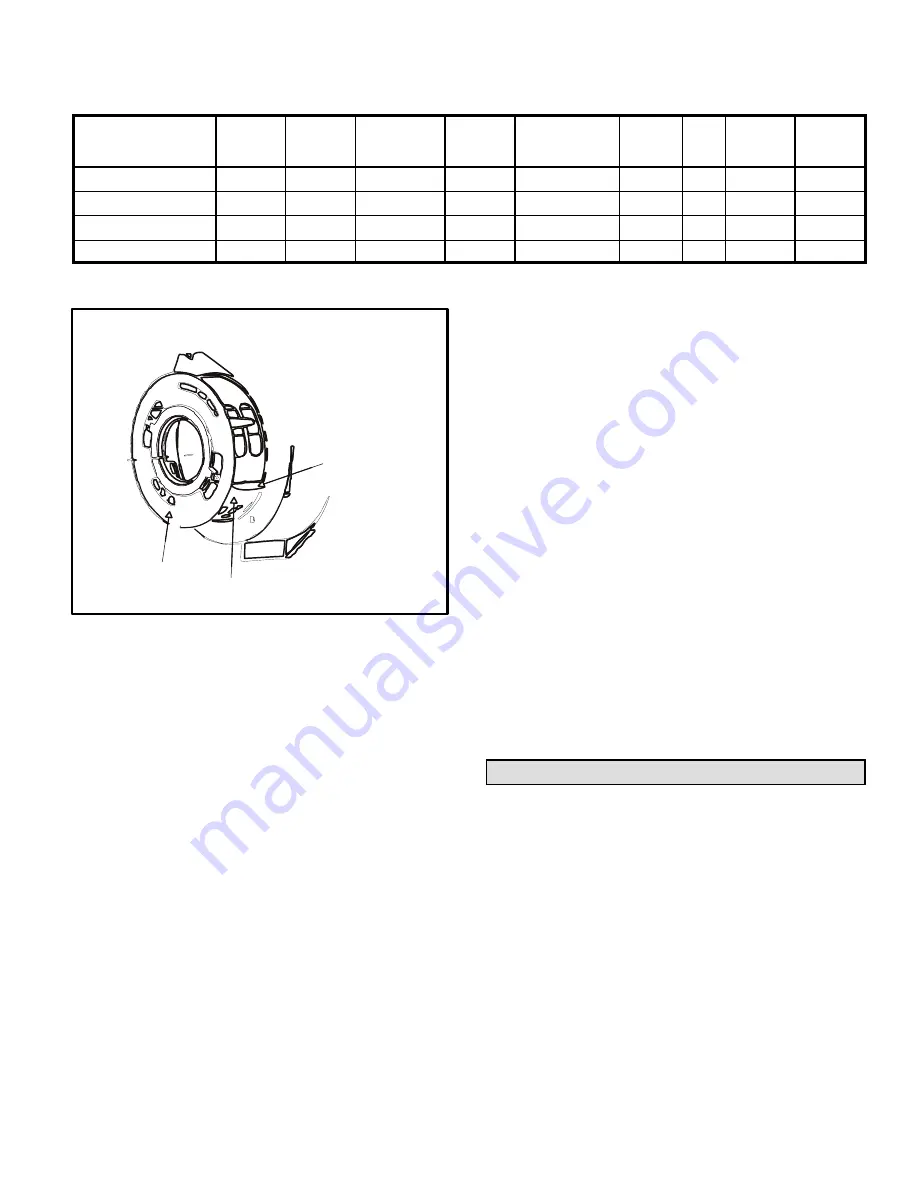

Air Band

(Secondary)

Air Shutter / Band Adjustment

Loosen this screw

to adjust air band.

Air Shutter

Air Band

Figure 19

3.

Smoke Test

The smoke test should be taken at the

hole drilled in step 1.

Using a smoke test gun, adjust the air so that you will

have just a trace (between 0 and #1) of smoke. If the

burner is producing more than #1 smoke, adjust the air

shutter (primary) and air band (secondary) to reduce

the smoke. See figure 19. To adjust the air shutter,

loosen the top screw on the air shutter (and lower

screw, if necessary). Then, rotate the shutter until the

desired smoke level is achieved. If smoke cannot be

reduced to the desired level by moving the air shutter,

adjust the air band to increase the air. To adjust the air

band, loosen the air band screw and rotate the

band.

This is the

starting

point.

Do not stop here.

4.

CO

2

Test

Again, take this sample at the vent pipe.

With the unit firing at a trace of smoke, take a sample of

the CO

2

. From the results of this test, a window of op-

eration" will be determined. This window of operation

establishes some tolerance. The tolerance the installer

builds in provides room within the set-up for those

things which might affect combustion. Those things

which might affect combustion can then do so without

causing the unit to start sooting/smoking. Things which

might affect combustion include a nozzle going bad,

draft that changes during different climatic conditions,

dirty oil, dirt obstructing the air inlet, etc.

To build in a window of operation," set up the burner to

be 2% less in CO

2

. For example, if you find a reading of

12% CO

2

, adjust the air shutter (and air band, if neces-

sary) to increase the air and drop the CO

2

to 10%.

5.

Retest the Smoke

With a drop in the CO

2

and in-

crease in the air you should see that the smoke has re-

turned to 0.

6.

Retest the Overfire Draft

This test serves to confirm

that you have not increased the air too much. Again

you do not want a positive pressure at the test port. It

should still be 0.02 less than the draft pressure reading

taken at the breach. You may need to increase the

stack draft by adjusting the barometric draft control.

7.

Stack Temperature

Take a stack temperature read-

ing in the vent pipe. Subtract the room air temperature

from the stack temperature. This will give you the net

stack temperature. Use the efficiency charts provided

in most CO

2

analyzers to determine furnace efficiency.

8. When the proper combustion and smoke readings

have been achieved, re−tighten the air shutter screw(s)

and air band screw.

Service

A − Servicing Filter

NOTE − Under no circumstances should the access panels

to the blower compartment be left off or left partially open.

1 − Throw-Away Type Filters Filters should be checked

monthly and replaced when necessary to assure prop-

er furnace operation. Replace filters with like kind and

size filters.

2 − Reusable Type Filters Filters should be checked

monthly and cleaned when necessary to assure prop-

er furnace operation. Use warm water and a mild de-

tergent. Replace filter when dry. Permanent filters

supplied with SLO183B furnaces do not require oiling

after cleaning. Examine filter label for any for special

instructions that may apply.