Page 18

ADJUST

The

ADJUST

pins affect blower motor speed during cool-

ing operation only. The ADJUST feature allows the motor to

run at normal speed, approximately 15% higher than nor-

mal speed, or 15% lower than normal speed during the

cooling mode. Table 7 gives three rowsNORM, (+), and

(–) with their respective CFM volumes. Notice that the nor-

mal NORM" adjustment setting for cool speed position C

in table 7 is 800 CFM. The (+)" adjustment setting for that

position is 920 CFM (115% of 800 CFM) and the (–)" ad-

justment setting is 680 CFM (85% of 800 CFM). After the

adjustment setting has been determined, choose the re-

maining speed settings from those offered in the table in

that row.

HEAT

The unit is factory−set to run at the middle of heating rise

range as shown on the unit rating plate. The jumper on the

tap marked

HEAT

must remain in the position given in table

7.

The

HEAT

jumper is used to determine CFM during heating

operation only. These jumper selections are activated only

when W1 is energized.

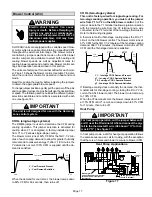

During the heat ON delay, the blower runs at 13% CFM for

the first minute, 50% CFM for the second minute, and full

CFM after two minutes.

OFF

CALL

100%

82%

50%

13%

W

60

sec

60

sec

210 seconds

w

W − Heat Demand Present

w − Heat Demand Satisfied

When the demand for heat is met, the blower ramps down

to 82% CFM for 3−1/2 minutes, then turns off.

TEST

The TEST pin is available to bypass the blower control and

run the motor at approximately 70% to make sure that the

motor is operational. This is used mainly in troubleshoot-

ing. The G terminal must be energized for the motor to run.

CFM LED

The

CFM

LED located on the blower control flashes one

time per 100 cfm to indicate selected blower speed. For ex-

ample, if the unit is operating at 1000 CFM, the

CFM

LED

will flash 10 times.

At times, the light may appear to flicker or glow. This takes

place when the control is communicating with the motor be-

tween cycles. This is normal operation.

After the CFM for each application has been determined,

the jumper settings must be adjusted to reflect those given

in table 7. From the table, determine which row most close-

ly matches the desired CFM. Once a specific row has been

chosen (+, NORMal, or −), CFM volumes from other rows

cannot be used. Below are descriptions of the jumper

selections.

The variable speed motor slowly ramps up to and down

from the selected air flow during both cooling and heating

demand. This minimizes noise and eliminates the initial

blast of air when the blower is initially energized.

Continuous Fan

When the thermostat is set for Continuous Fan" operation

and there is no demand for heating or cooling, the blower

control will provide 50% of the

COOL

CFM selected.

OFF

CALL

50%

G

g

G − Fan switch ON

g − Fan switch OFF

NOTE − With the proper thermostat and subbase, continu-

ous blower operation is possible by closing the R to G cir-

cuit.

Dehumidification

The A54 blower control (see figure 18) includes a HUM ter-

minal which provides for connection of a humidistat. The

JW1 jumper on the blower control must be cut to activate

the HUM terminal. The humidistat must be wired to open on

humidity rise. When the dehumidification circuit is used,

the variable speed motor will reduce the selected air flow

rate by 18% when humidity levels are high. An LED (D1)

lights when the blower is operating in the dehumidification

mode.

Humidification

Terminals are provided on the A15 control for 120 volt out-

put to operate a humidifier. The HUM" terminal is ener-

gized when there is a call for heat. See figure 14.

Indoor Air Quality (IAQ) Accessory

An EAC terminal is provided on the A15 control for 120 volt

output to an indoor air quality accessory. The EAC terminal

is energized when there is a call for heat, cool, or continu-

ous blower. See figure 14.