Page 12

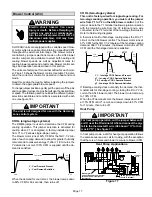

Both conditions require that you use a two−pipe system,

which consists of a return line that purges the fuel pump of

air by returning it to the tank. To determine the run and lift for

piping, refer to table 4.

Figure 13

Oil Piping

ÎÎÎÎÎÎÎÎÎÎÎÎÎ

ÎÎÎÎÎÎÎÎÎÎÎÎÎ

ÎÎÎÎÎÎÎÎÎÎÎÎÎ

ÎÎÎÎÎÎÎÎÎÎÎÎÎ

ÎÎÎÎÎÎÎÎÎÎÎÎÎ

Fuel

Pump

Aux

Filter

Return

pipe

Fill

Pipe

Air Vent

Oil

Tank

Inlet

Return

Pipe

H

3"−4"

(76 mm −102 mm)

R

Outside tank fuel pump above bottom of tank

Two-Pipe System

Use continuous lengths of heavy wall copper tubing or

steel pipe for oil supply pipe. Install oil supply pipe under

floor or near walls to protect it from damage. Avoid running

pipes along joists or reverberating surfaces. Always use

flare fittings. All fittings must be accessible. Do not use

compression fittings.

IMPORTANT

Both oil supply and return pipes must be submerged

in oil in the supply tank.

Table 4

Two−Pipe Maximum Pipe Length (H + R)

Lift H"

3450 RPM − 3 GPH (11.4 LPH)

3/8" (10 mm) OD

Tubing

1/2" (12 mm) OD

Tubing

Single

Stage

Two

Stage

Single

Stage

Two

Stage

0’

(0.0 m)

84’

(25.6 m)

93’

(28.3 m)

100’

(30.5 m)

100’

(30.5 m)

2’

(0.6 m)

73’

(22.3 m)

85’

(25.9 m)

100’

(30.5 m)

100’

(30.5 m)

4’

(1.2m)

63’

(19.2 m)

77’

(23.5 m)

100’

(30.5 m)

100’

(30.5 m)

6’

(1.8m)

52’

(15.8 m)

69’

(21.0 m)

100’

(30.5 m)

100’

(30.5 m)

8’

(2.4m)

42’

(12.8 m)

60’

(18.3 m)

100’

(30.5 m)

100’

(30.5 m)

10’

(3.0m)

31’

(9.4 m)

52’

(15.9 m)

100’

(30.5 m)

100’

(30.5 m)

12’

(3.7m)

21’

(6.4 m)

44’

(13.4 m)

83’

(25.3 m)

100’

(30.5 m)

14’

(4.3m)

−−−

36’

(11.0 m)

41’

(12.5 m)

100’

(30.5 m)

16’

(4.9m)

−−−

27’

(8.2 m)

−−−

100’

(30.5 m)

18’

(5.5m)

−−−

−−−

−−−

76’

(23.2 m)

Table 5

Fuel Pump Usage

Pump

Piping Application

Maximum Lift (vacuum)

Single−Stage Pump

One−Pipe System

8 ft. (6" Hg vacuum)

Two−Pipe System

10 ft. (12" Hg vacuum)

Two−Stage Pump

Two−Pipe System

10 ft. or greater

(12" to 17" Hg vacuum)