Page 39

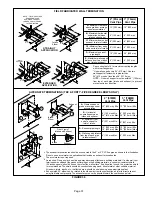

F- Proper Gas Flow (Approximate)

Gas Flow (Approximate)

TABLE 18

GAS METER CLOCKING CHART

ML193

Unit

Seconds for One Revolution

Natural

LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

DIAL

-045

80

160

200

400

-070

55

110

136

272

-090

41

82

102

204

-110

33

66

82

164

Natural-1000 btu/cu ft LP-2500 btu/cu ft

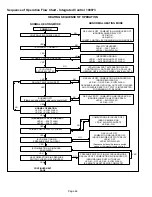

NOTE

- To obtain accurate reading, shut off all other gas

appliances connected to meter.

Furnace should operate at least 5 minutes before checking

gas flow. Determine time in seconds for

two

revolutions of

gas through the meter. (Two revolutions assures a more

accurate time).

Divide by two

and compare to time in table

18. If manifold pressure matches table 19 and rate is incor

rect, check gas orifices for proper size and restriction. Re

move temporary gas meter if installed.

TABLE 19

Manifold and Supply Pressure (Outlet) inches w.c.

At All Altitudes For -1 Through -6 Units

Fuel

Model

Input Sizes

Manifold

Pressure in.wg.

Supply

Pressure in.wg.

Min.

Max.

Nat. Gas

All sizes

3.5

4.5

13.0

L.P. Gas

All sizes

10.0

11.0

13.0

G- Proper Combustion

Furnace should operate at least 15 minutes with correct

manifold pressure and gas flow rate before checking com

bustions. Take sample beyond the flue outlet and compare

to table 20.

TABLE 20

ML193

Unit

CO

2

%

For Nat

CO

2

%

For L.P.

-045

7.2 - 7.9

8.6 - 9.3

-070

-090

-110

The carbon monoxide reading should not exceed 50 ppm.

H- High Altitude

NOTE

- In Canada, certification for installations at eleva

tions over 4500 feet (1372 m) is the jurisdiction of local au

thorities.

ML193DF-1 through -6 units require no manifold pressure

adjustments for operation at altitudes up to 10,000 feet

(3048 m) above sea level. However, -7 units and later in

stalled at altitude of 4501 - 10,000 feet (1373 to 3048m) re

quire a pressure switch change which can be ordered sep

arately and manifold de-rate. See table 19 or table 21 for

manifold pressures at varying altitudes. Table 22 lists con

version kit and pressure switch requirements at varying al

titudes.

The combustion air pressure switch is factory-set and re

quires no adjustment.

TABLE 21

Manifold and Supply Line Pressure 0-10,000ft. For -7 Units and Later

ML193

Unit

Gas

Manifold Pressure in. wg.

Supply Line

Pressure

in. w.g.

0 - 10000 ft.

0-4500 ft.

4501-5500 ft.

5501-6500 ft.

6501 -

7500ft.

7501 - 10000ft.

All Sizes

Natural

3.5

3.3

3.2

3.1

3.5

4.5

13.0

LP/propane

10.0

9.4

9.1

8.9

10.0

11.0

13.0

NOTE -

A natural to L.P. propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit installation instruction for the conversion

procedure.

TABLE 22

Conversion Kit and Pressure Switch Requirements at Varying Altitudes

ML193

Unit

Natural to

LP/Propane

High Altitude

Natural Burner Ori

fice Kit

LP/Propane to

Natural

High Altitude Pressure Switch

0 - 7500 ft

(0 - 2286m)

7501 - 10,000 ft

(2286 - 3038m)

0 - 7500 ft

(0 - 2286m)

4501 - 7500 ft

(1373 - 2286m)

7501 -10,000 ft

(2286 - 3048m)

-045

*69W73

73W37

*73W81

93W87

93W88

-070

-090

-110

* Conversion requires installation of a gas valve manifold spring which is provided with the gas conversion kit.

Pressure switch is factory set. No adjustment necessary. All models use the factory-installed pressure switch from 0-4500 feet (0-1370 m).