Page 16

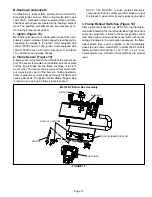

8. Combustion Air Inducer (B6)

& Cold End Header Box

All ML193DF units use a combustion air inducer to move air

through the burners and heat exchanger during heating op

eration. The blower uses a shaded pole 120VAC motor.

The motor operates during all heating operation and is con

trolled by burner ignition control A3. Blower operates con

tinuously while there is a call for heat. The burner ignition

control will not proceed with the ignition sequence until

combustion air inducer operation is sensed by the proving

switches.

The CAI is installed on the cold end header box. The cold

end header box is a single piece made of hard plastic. The

box has an internal channel where the combustion air in

ducer creates negative pressure at unit start up. The chan

nel contains an orifice used to regulate flow created by the

CAI. The box has pressure taps for the CAI pressure switch

hoses. The pressure switch measure the pressure across

the CAI orifice or difference in the channel and the box.

If

replacement is necessary the gaskets used to seal the

box to the vestibule panel and the CAI to the box, must

also be replaced.

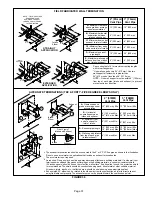

TABLE 9

ML193DF Unit

C.A.I. Orifice Size

-045

0.618

-070

0.891

-090

1.031

-110

1.297

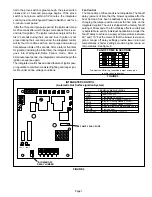

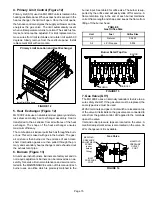

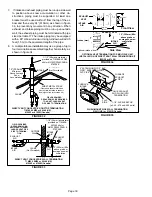

9. Combustion Air Pressure Switch

(Figure 15)

ML193DF series units are equipped with a differential pres

sure switch located on the cold end header box. The

switches monitor across the CAI orifice to insure proper

flow through the heat exchanger.

The switch is a SPST N.O. prove switch electrically con

nected to the integrated control. The purpose of the switch

is to prevent burner operation if the combustion air inducer

is not moving enough air for proper combustion.

FIGURE 15

Pressure Switch

24VAC

TERMINALS

BRACKET

TAP

TAP

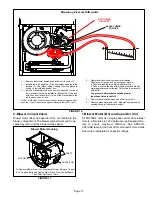

On start‐up, the switch senses that the combustion air in

ducer is operating. It closes a circuit to the ignition control

when the difference in pressure across the CAI orifice ex

ceeds a non-adjustable factory setting. If the switch does

not successfully sense the required differential, the switch

cannot close and the furnace cannot operate. If the flue or

air inlet become obstructed during operation, the switch

senses a loss of pressure differential and opens the circuit

to the ignition control. If the condensate line is blocked, wa

ter will back up into the header box and reduce the pressure

differential across the switch. The prove switch opens if the

differential drops below the set point. See table 10.

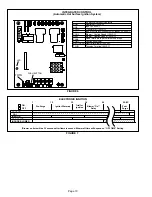

Checks of pressure differential can aid in troubleshooting.

When measuring the pressure differential, readings should

be taken at the pressure switch. See figure 16. Lack of dif

ferential usually indicates problems in the intake or exhaust

piping, but may indicate problems in the heat exchanger,

condensing coil, header boxes, combustion inducer or oth

er components.

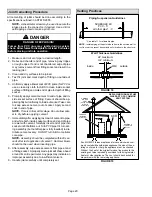

TABLE 10

ML193DF

Altitude ft

0 - 4500

4501 -

7500

7501 - 10000

Set Point

SetPoint

Set Point

-045

-0.65

-0.60

-0.55

-070

-090

-110

*Set point is factory set and non-adjustable