Page 8

C-Installation on Cooling Cabinet

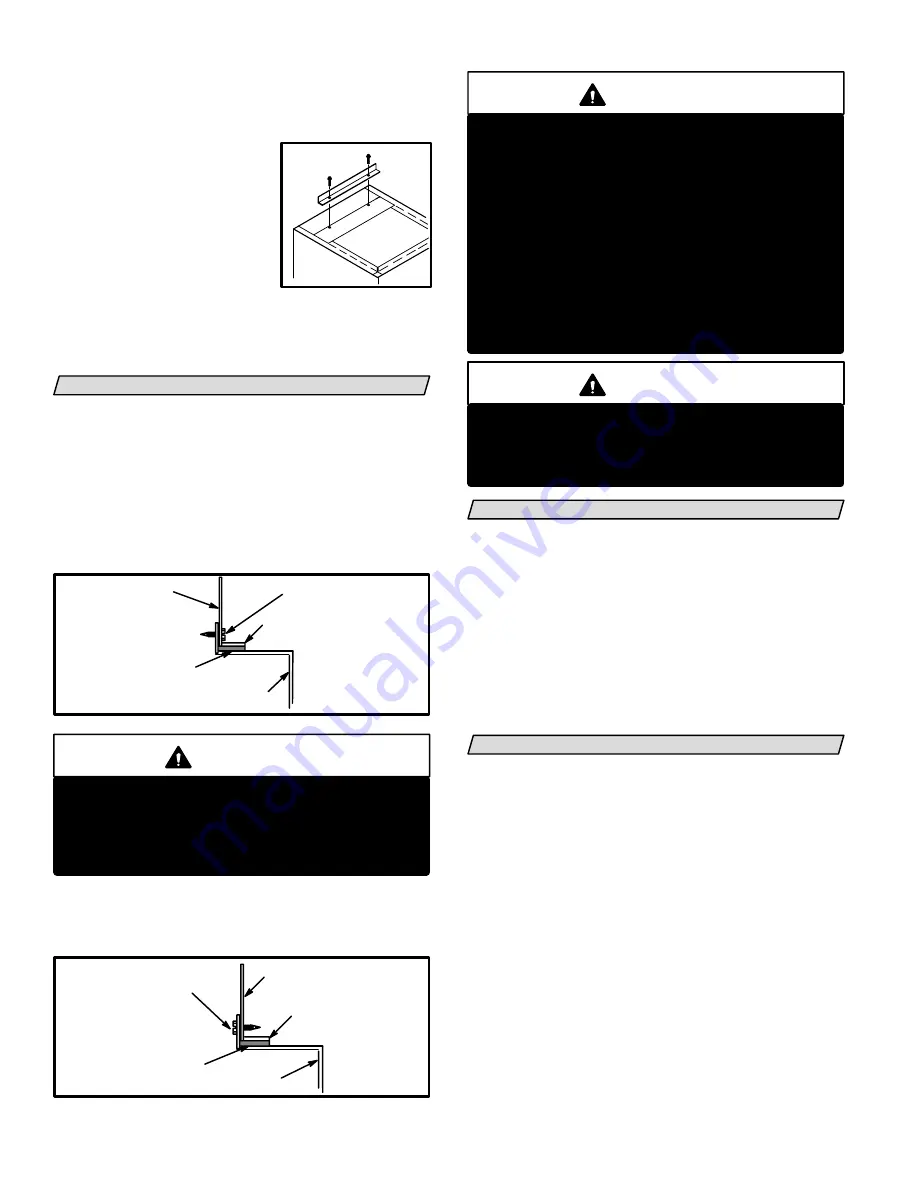

1- Refer to reverse-flow coil installation instructions for corĆ

rectly sized opening in floor and installation of cabinet.

2- Use duckbill pliers to bend

unit flanges out from openĆ

ing. Install provided base

bottom angle (shipped in

vestibule panel) to outside of

base into provided holes.

See illustration at right. SeĆ

cure with screws provided.

3- With cooling cabinet in place, install furnace so

flanges drop inside cabinet opening. Secure furnace

to cabinet.

4- Seal cabinet and check for air leakage.

RETURN AIR OPENING GUIDELINES

Take the following steps when installing return air

plenum:

1- Bottom edge of plenum should be flanged with a

hemmed edge. See figure 8.

2- Fiberglass sealing strips should be used between pleĆ

num and the unit cabinet to ensure a tight seal.

3- In all cases, the plenum should be secured to the top

flanges of the furnace using sheet metal screws. See

figure 8.

FIGURE 8

SECURE

HEMMED EDGE

PLENUM

CABINET SIDE PANEL

FIBERGLASS

SEALING STRIP

WARNING

Do not put sheet metal screws into top of furnace.

Sheet metal screws must be installed into flange of

furnace. Note warning stickers on unit. MisplaceĆ

ment of screws may prevent normal maintenance

of filters.

4- In closet installations, it may be necessary to install

sheet metal screws from the inside. If this is the case,

make plenum with a removable front to install screws

as shown in figure 9.

FIGURE 9

SECURE FROM

INSIDE

HEMMED EDGE

FIBERGLASS

SEALING STRIP

CABINET SIDE PANEL

PLENUM

WARNING

Improper installation of unit can result in personal

injury or death. Combustion and flue products must

never be allowed to enter the return air system or air

in the living space. Use sheet metal screws and joint

tape to seal return air system to furnace.

The furnace should be sealed airtight to the return

air plenum. A door must never be used as a portion

of the return air duct system. Allow absolutely no

sagging, cracks, gaps, etc.

For no reason should return and supply air duct

systems ever be connected to or from other heatĆ

ing devices such as a fireplace or stove, etc. Fire,

explosion, carbon monoxide poisoning, personal

injury and/or property damage could result.

WARNING

Blower door must be securely in place when blowĆ

er and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into

living space resulting in personal injury or death.

DUCT SYSTEM

Size and install the supply and return air duct system usĆ

ing industry-approved standards that result in a quiet

and low-static system with uniform air distribution.

Installation of units not equipped with a cooling coil reĆ

quire a removable access panel in the supply air duct.

The access panel should be large enough to permit inĆ

spection of heat exchanger for leaks after installation.

Lennox recommends using the SENSIT

TM

HT kit for

heat exchanger inspections. The access panel must not

allow leaks in the supply air duct system.

VENTING

G20R furnaces must be vented in compliance with all

local codes, the current GAMA/A.G.A. venting tables

manual (502,567M) in the U.S.A. and the current stanĆ

dards of CAN/CGA-B149.1 and -B149.2 in Canada and

these instructions.

The G20R series units have been classified as Category

I type furnaces when vertically vented in accordance

with the latest edition of ANSI Z21.47 Central Furnace

Standard in the U.S.A. and the current standard of

CAN/CGA-B149.1 and B149.2 of the National Gas and

Propane Installation Code in Canada.

General Venting Recommendations & Requirements

For Using Masonry Chimney

Any masonry chimney used for venting a G20R gas furĆ

nace must be lined, and must be sized and installed per

all applicable local building codes or, in the absence of

local codes, the current National Fuel Gas Code (ANSI-

Z223.1) in the U.S.A. and the current standards of CAN/

INSTALLING

BASE ANGLE