Page 6

building of tight construction with weather stripping

and caulking around the windows and doors, follow

the procedures outlined for using air from the outside

for combustion and ventilation.

Confined Space

A confined space is an area with volume less than 50 cuĆ

bic feet per 1,000 Btu per hour of the combined input ratĆ

ing of all appliances installed in that space. This definiĆ

tion includes furnace closets or small equipment rooms.

When the furnace is installed so that supply ducts carry

air circulated by the furnace to areas outside the space

containing the furnace, the return air must be handled

by ducts which are sealed to the furnace casing and

which terminate outside the space containing the furĆ

nace. This is especially important when the furnace is

mounted on a platform in a confined space such as a

closet or small equipment room. Even a small leak

around the base of the unit at the platform or at the reĆ

turn air duct connection can cause a potentially danĆ

gerous negative pressure condition. Air for combusĆ

tion and ventilation can be brought into the confined

space either from inside the building or from outside.

Air from Inside

If the confined space housing the furnace adjoins space

categorized as unconfined, air can be brought in by proĆ

viding two permanent openings between the two

spaces. Each opening must have a minimum free area of

1 square inch per 1,000 Btu per hour of total input rating

of all gas-fired equipment in the confined space. Each

opening must be at least 100 square inches. One opening

shall be within 12 inches of the top of the enclosure and

one opening within 12 inches of the bottom. See figure 3.

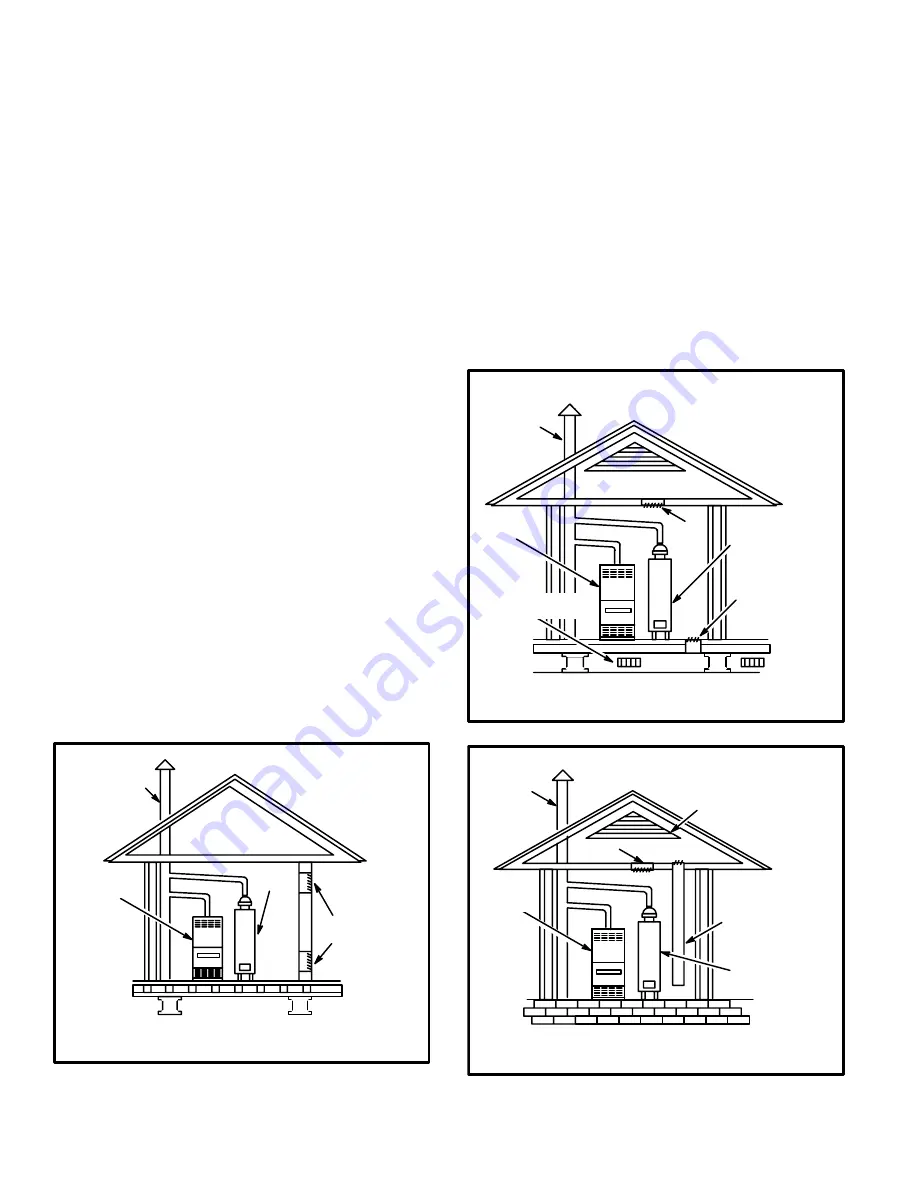

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM INSIDE

WATER

HEATER

OPENINGS

(To Adjacent

Room)

FIGURE 3

NOTE-Each opening shall have a free area of at least one

square inch per 1,000 Btu per hour of the total input rating of all

equipment in the enclosure, but not less than 100 square inches.

G20R

FURNACE

CHIMĆ

NEY OR

GAS

VENT

Air from Outside

If air from outside is brought in for combustion and venĆ

tilation, the confined space must have two permanent

openings. One opening shall be within 12 inches of the

top of the enclosure and one within 12 inches of the botĆ

tom. These openings must communicate directly or by

ducts with the outdoors or spaces (crawl or attic) that freeĆ

ly communicate with the outdoors or indirectly through

vertical ducts. Each opening shall have a minimum free

area of 1 square inch per 4,000 Btu per hour of total input

rating of all equipment in the enclosure. See figures 4 and

5. When communicating with the outdoors through horiĆ

zontal ducts, each opening shall have a minimum free

area of 1 square inch per 2,000 Btu per total input rating of

all equipment in the enclosure. See figure 6.

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(Inlet Air from Crawl Space and Outlet

Air to Ventilated Attic)

NOTE-The inlet and outlet air openings shall each have a

free area of at least one square inch per 4,000 Btu per hour

of the total input rating of all equipment in the enclosure.

VENTILATION LOUVERS

(Each end of attic)

OUTLET

AIR

WATER

HEATER

INLET

AIR

CHIMNEY

OR GAS

VENT

FIGURE 4

G20R

FURNACE

VENTILATION

LOUVERS

(For unheated crawl space)

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

NOTE-The inlet and outlet air openings shall each have a free area of

at least one square inch per 4,000 Btu per hour of the total input rating

of all equipment in the enclosure.

CHIMNEY

OR GAS

VENT

WATER

HEATER

OUTLET

AIR

VENTILATION LOUVERS

(Each end of attic)

INLET AIR

(Ends 12" above

bottom)

FIGURE 5

G20R

FURNACE