Page 10

506120−01 03/10

Brazing Connections

WARNING

Polyol ester (POE) oils used with HFC−410A

refrigerant absorb moisture very quickly. It is very

important that the refrigerant system be kept

closed as much as possible. DO NOT remove line

set caps or service valve stub caps until you are

ready to make connections.

WARNING

Danger of fire. Bleeding the

refrigerant charge from only the high

side may result in the low side shell

and suction tubing being

pressurized. Application of a brazing

torch while pressurized may result in

ignition of the refrigerant and oil

mixture − check the high and low

pressures before unbrazing.

WARNING

When using a high pressure gas such

as dry nitrogen to pressurize a

refrigeration or air conditioning

system, use a regulator that can

control the pressure down to 1 or 2

psig (6.9 to 13.8 kPa).

CAUTION

Brazing alloys and flux contain materials which are

hazardous to your health.

Avoid breathing vapors or fumes from brazing

operations. Perform operations only in well

ventilated areas.

Wear gloves and protective goggles or face shield

to protect against burns.

Wash hands with soap and water after handling

brazing alloys and flux.

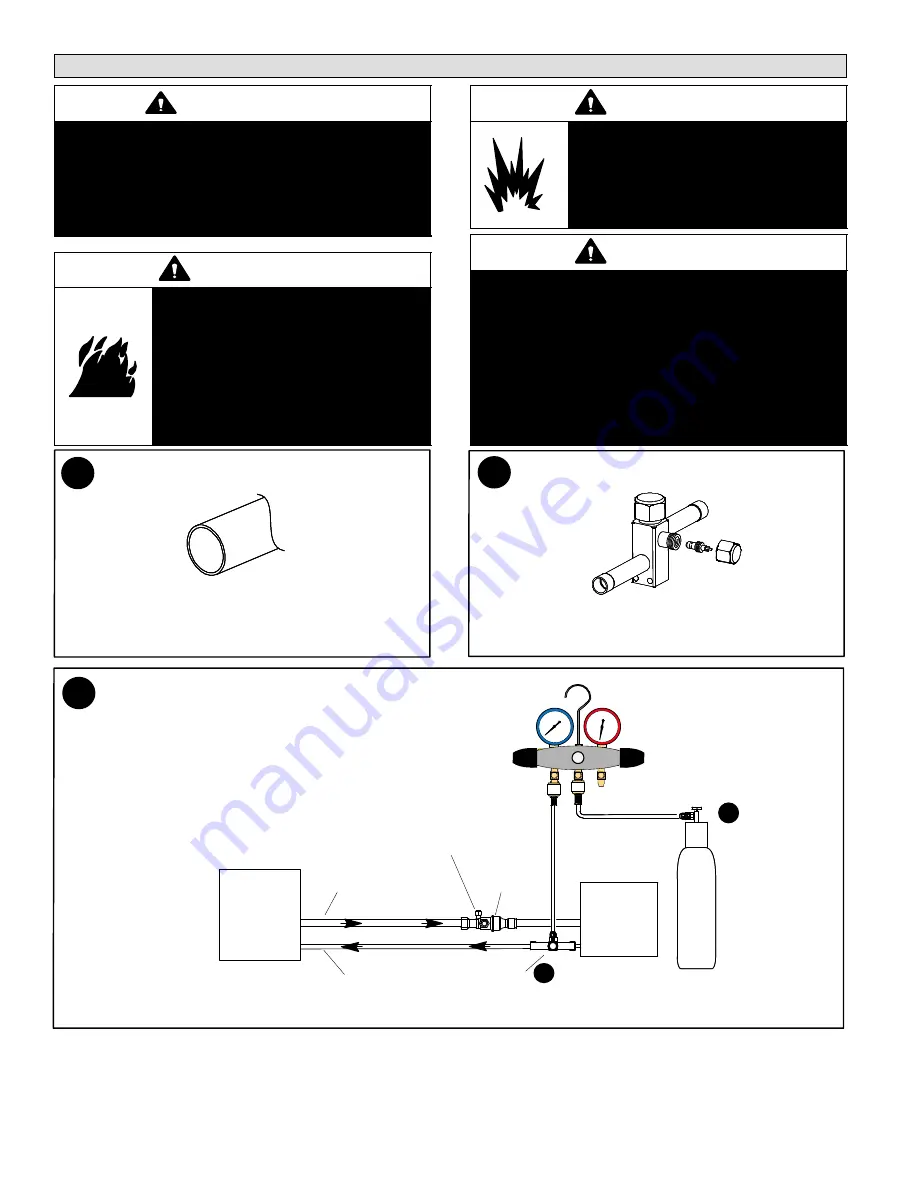

1

2

CUT AND DEBUR

CAP AND CORE REMOVAL

Cut ends of the refrigerant lines square (free from nicks or

dents). Debur the ends. The pipe must remain round, do not

pinch end of the line.

Remove service cap and core from both the suction and liquid

line service ports.

3

ATTACHED GAUGES

OUTDOOR

UNIT

LIQUID LINE

SUCTION LINE

LIQUID LINE

SERVICE

VALVE

SUCTION LINE

SERVICE

VALVE

ATTACH

GAUGES

INDOOR UNIT

SERVICE PORT MUST BE

OPEN TO ALLOW EXIT

POINT FOR NITROGEN

A

Connect gauge set low pressure side to liquid line service valve.

B

Connect gauge set center port to bottle of nitrogen.

NITROGEN

A

B