Page 30

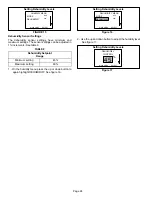

TOP VIEW

Opening

1-5/8

(41)

SIDE VIEW

1-5/8

(41)

11-3/8

(289)

2 (51)

1-5/8

(41)

22-1/8

(562)

5/8

(16)

13-3/8 (340)

SUPPLY

AIR

OPENING

FIGURE 23

Inches

(mm)

23−1/4

(591)

DOWNFLOW COMBUSTIBLE BASE DIMENSIONS

20 (508)

D−Horizontal Right−Hand

Discharge Application

NOTE−For horizontal applications, a secondary drain pan is

recommended. Refer to local codes.

1− Before operating the unit, remove access panels and

the horizontal drip shield (−068 model) and the

corrugated padding between the blower and coil

assembly. Discard the corrugated padding and the

downflow drip shields from the foam pads on top of the

unit.

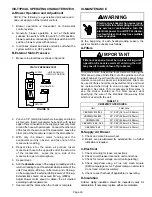

2− Install the horizontal shield on the front edge of the

horizontal drain pan as shown in figure 24.

3− No further adjustment is necessary. Set unit so it is

sloped toward the drain pan (1/4" [6mm]). See figure

24.

4− If hanging the unit, it must be supported along the entire

length of the cabinet. If using chain or strap, use a piece

of angle iron or sheet metal attached to the unit (either

above or below) so that the full length of the cabinet is

supported. Use securing screws no longer than 1/2"

(13mm) to avoid damage to coil or filter. See figure

25. Connect return and supply air plenums as

required using sheet metal screws.

NOTE−For horizontal applications in

high humidity

areas

, remove the downflow rail closest to the drain pan.

Removal of downflow rail will prevent sweating in high

humidity areas. To remove rail, remove screw from rail at

back of unit and at cabinet support rail. Remove downflow

rail then replace screws. Also, seal around the exiting

drain pipe, liquid and suction lines to prevent infiltration of

humid air.

FIGURE 24

RIGHT−HAND DISCHARGE CONFIGURATION

No Adjustment Is Necessary

HORIZONTAL DRIP

SHIELD (−068 MODELS)

UPFLOW / DOWN-

FLOW DRAIN PAN

HORIZONTAL

DRAIN PAN

DOWNFLOW

RAIL

FIGURE 25

HANGING HORIZONTAL UNIT

FRONT VIEW

END VIEW

ANGLE IRON

OR

SHEET METAL

Electrical Inlet

Clearance

4 in. (102 mm)

1/2" (13mm) Screws max.

CAUTION

Danger of equipment damage and personal injury.

Take care when removing coil assembly from unit

installed in right or left−hand applications. Coil

may tip into drain pan once clear of cabinet. Sup-

port coil when removing.