506794-01

Page 6 of 16

Issue 1243

Combustion and Ventilation Air

Adequate provisions for combustion air, ventilation of

furnace, and dilution of the gases must be made. When a

furnace is installed in an unconfined space in a building, it

can be assumed that infiltration will be sufficient to supply

the required air.

If the furnace is installed in a confined space and

combustion air is taken from the heated space, the supply

air and ventilating air must be through two permanent

openings of equal area. A confined space is “a space

whose volume is less than 50 cubic feet per 1000 btu per

hour of the combined input rating of all appliances installed

in that space.” One opening must be within 12” of the

ceiling and the other within 12” of the floor. Each opening

must have a minimum free area of at least 1 square inch

per 1000 btu per hour of total input rating of all appliances

with the space but not less than 100 square inches.

If the furnace is installed in a space within a building of

tight construction, air must be supplied from outdoors. In

this case, one opening shall be within 12” of the ceiling and

the other within 12” of the floor. If vertical combustion ducts

are run, each opening must have a free area of at least 1

square inch per 4000 btu per hour. If horizontal combustion

ducts are run, 1 square inch per 2000 btu per hour of the

total input of all appliances is required.

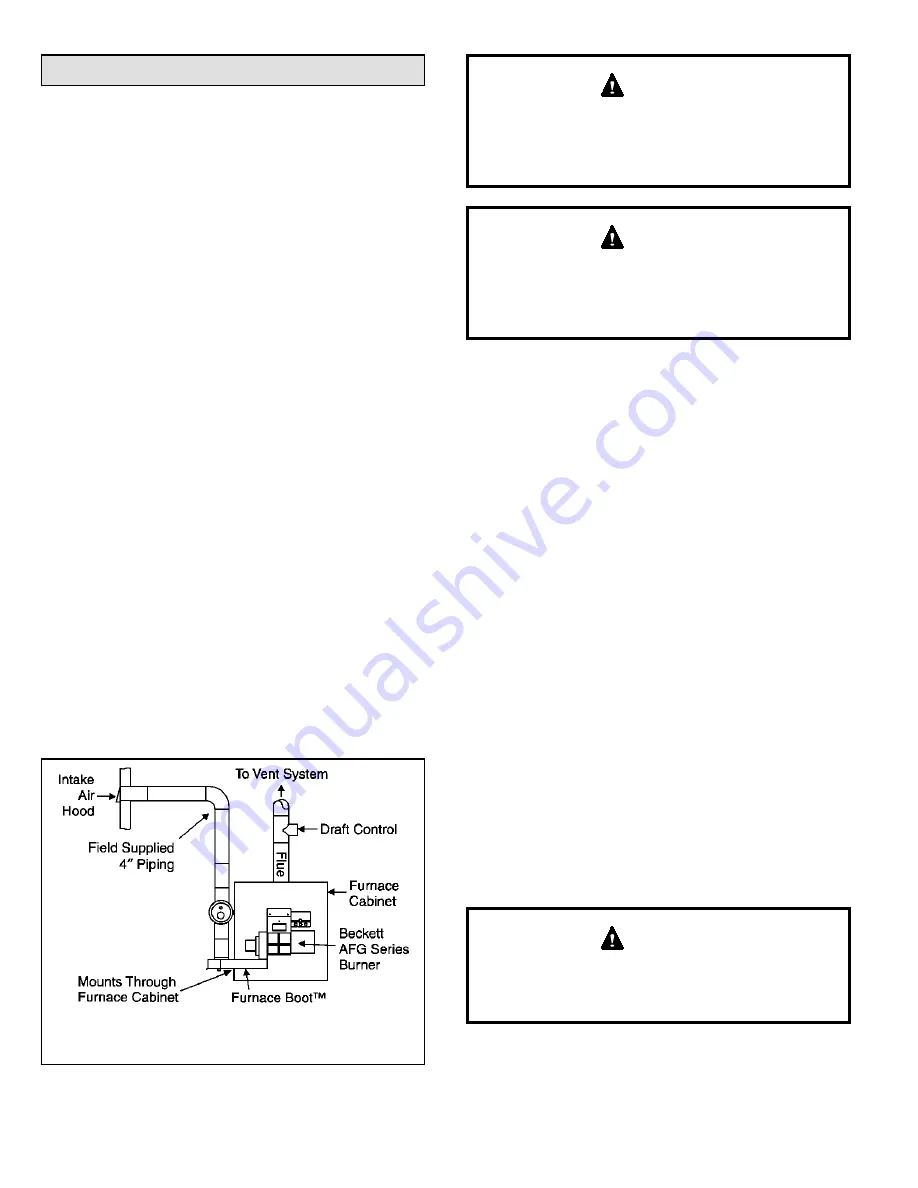

The furnace is designed to use air inside the dwelling

for combustion. If additional combustion air is required,

installing fresh air kit ABOOT571 allows air from outside

the dwelling to be brought in to the oil burner. This kit brings

air into the burner through air inlet ductwork run through

the furnace cabinet side panel and terminated outside the

dwelling (see Figure 5). The kit includes a vacuum relief

valve to guard against combustion problems associated

with directly connecting oil burners to the outside.

Figure 5. Fresh Air Kit ABOOT571 Installation

IMPORTANT

: No more than 10’ of vertical piping allowed without

weight support.

Combustion air openings in the front of the furnace

must be kept free of obstructions. Any obstruction will

cause improper burner operation and may result in a

fire hazard or injury.

WARNING

The barometric control shall be in the same atmospheric

pressure zone as the combustion air inlet to the furnace.

Deviation from this practice will cause improper burner

operation and may result in a fire hazard or injury.

WARNING

Circulating Air Supply

A return air duct system is recommended. Where there is

no complete return air duct system, a return connection

should be run full size to a location outside the confined

space and completely sealed so that no air from the

confined space can be circulated through the heating duct

system.

Outdoor Make Up Air

A minimum mixed return air temperature of 60 - 65°F

must be maintained for outdoor make up air to prevent

condensation and corrosion.

Venting

Chimney

Before installing the furnace, a thorough inspection of the

chimney should be made to determine whether repairs

are necessary and that the chimney is of the proper size

and constructed in accordance with the requirements

of the National Board of Fire Underwriters or Canadian

Standards Association. The smallest dimension of the

chimney should be at least equal to the diameter of the

flue pipe of the furnace. Be sure the chimney will produce

a steady draft sufficient to remove all the products of

combustion from the furnace. A fabricated vent system the

same size as the flue outlet of the furnace may also be

used. If a manufactured vent is used, it must be listed for

use with oil-fired equipment.

This furnace is certified for use with Type “L” vent, Type

“A”, and “factory-built” chimneys. “B” vent must not be

used with oil furnaces.

WARNING