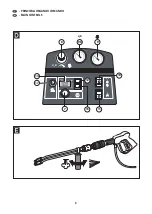

> MACHINE DESCRIPTION

see fig.

A

①

Detergent tank

②

Handle

③

High pressure water outlet

④

Electric cable

⑤

Water inlet

⑥

Diesel tank

see fig.

D

⑦

EMERGENCY STOP

⑧

dry steam / wet steam adjuster

⑨

Pressure gauge steam

9b

Pressure gauge water

⑩

Main switch ON/OFF

⑪

Boiler switch

⑫ +

temperature adjuster

⑬

- temperature adjuster

⑭

Thermo regulator display

- Temperature indicator

- Indicates "H2O” when water is missing from

the tank.

- Indicates "GAS" when diesel is missing from

the tank.

see fig.

A

⑮

Steam gun

⑯

Steam accessory

⑰

Detergent spray switch

⑱

High pressure hose

⑲

Lance

⑳

Drain hose valve

> INSTALLATION AND START-UP

IMPORTANT: The machine installation en-

vironment should be kept at between 10°C and

35°C.

FUELLING

DIESEL

(see fig.

A)

18 l

Fill the tank with the fuel indicated on the technical

data plate (Diesel)

In order not to damage the fuel pump, ensure that

the tank never empties while running.

•

WARNING: Use of unsuitable fuel may result in

dangerous situations.

DETERGENT

(see fig.

A)

4,8 l

Fill the detergent tank with the product recom-

mended for the task to be carried out.

•

WARNING: Make use only of liquid detergent, do not

absolutely use acid or too much alkaline products. We

suggest you to make use of our products, which have

been studied for the use with washer machines.

WATER

see fig.

A)

see section on "WATER SUPPLY"

- Connect the hose

⑱

to high pressure water

outlet

③

,

- then open the steam tap

③

.

> Temperature adjustment

(see fig.

D)

Adjust the temperature by means of the thermo re-

gulator situated on the control panel.

This machine is equipped with an electronic thermo

regulator to check and adjust the boiler temperatu-

re as well as the pressure from min. 5 bar to max.

10 bar.

- Connect the plug to the power socket.

- When turning the unit on, the display shows the

temperature reading in the boiler.

Adjust the temperature as follows:

- Hold the ( + ) and ( - ) buttons pressed simulta-

neously for a few seconds;

- Press the ( + ) button to increase the temperature,

or the ( - ) button to decrease it.

It is essential that the thermo regulator is set to

190°C in order to be able to work at 10 bar.

TABLE OF COMPARISON BETWEEN DEGREES CENTI-

GRADE AND STEAM PRESSURE EXPRESSED IN BAR

° C

bar

152

5

159

6

165

7

170

8

175

9

180

10

•

WARNING:

-

The machine is pre-set at the

max temperature of 190 °C.

- For any adjustment, timing

or replacement action not

described in this handbook,

contact qualified personnel at the

manufacturer or resale outlet.

- Adjustments can be made to adapt the machine

to various production requirements.

EN

17

Summary of Contents for Fuji

Page 3: ...H2 O H2 O H2 O 9 9b 7 14 17 13 11 10 12 8 PRINCIPALI ORGANI DI COMANDO MAIN CONTROLS E D 3...

Page 22: ...22...

Page 23: ...23...