Page A - 48

A

LW SC-300 E / LW SC-350 E

Version: 06.12.2022

M A I N T E N A N C E A N D S E R V I C E

Automatic condensation dump system

The compressor comes as standard with an automatic condensation dump system. Solenoids drain

all condensate separators every 15 minutes.

To test the system, press the blue condensate test drain button on the operating panel.

Oil / water separators

Condensate is separated after the 2nd and 3rd stage of

compression. All two oil / water separators are equipped

with electronic timer controlled solenoids. The timer is

located in the switch box and activates the dump valves

about every 15 minutes.

To release the complete condensate through the black plastic

hoses, we recommend using an 20 l container at least.

The drain noise can be kept to a minimum by using a

silencer.

Maintenance intervals

We recommend to clean oil and water separators every 500

operating hours or at least once a year, to check for corrosion

damage and to replace o-rings if necessary.

All oil / water separators have an integrated sinter filter which

has to be replaced every 1,000 operating hours.

Note

The collected condensate can contain oil and has to be disposed according to

regulations.

i

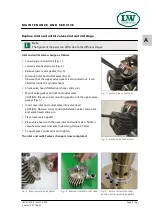

Oil / water separators 2nd stage

Oil / water separators final stage

Summary of Contents for SC-300 E

Page 3: ...A Operating Instructions Breathing Air Compressor LW SC 300 E LW SC 350 E Version 12 22 E...

Page 12: ...A S A F E T Y P R E C A U T I O N S...

Page 19: ...A I N S TA L L AT I O N...

Page 26: ...A O P E R AT I O N...

Page 34: ...A R E M E D Y I N G FA U LT S...

Page 39: ...A M A I N T E N A N C E A N D S E R V I C E...

Page 67: ...A M A I N T E N A N C E R E C O R D S...

Page 75: ...E A T T A C H M E N T Version 11 12 E...

Page 79: ...INFORMATIONON THE SERVICE LIFE OF L W HIGH PRESSURE HOSES...

Page 87: ...ANNEX...