OPERATION AND MAINTENANCE

4-9

Operating Speed

Operating speed is very significant to the performance of

the HSL. It requires some speed to make it work

correctly.

1.

The minimum operating speed should be

approximately 7-1/2 to 8 miles per hour unless the

goal is to minimize the percent of crop residue being

buried.

2.

Maximum operating speed recommended is

approximately 12 miles per hour.

Operating speed is a function of the amount of crop

residue that is buried.

• The higher the speed of operation of the HSL the

greater the percent of crop residue that will be buried.

• The slower the speed of operation of the HSL the

greater the percent of crop residue left that will be left

on the surface.

When operating the HSL, high speed can be a substitute

for operating deep. On the other hand, in some cases, it

is desirable to reduce the percentage of crop residue

buried. In such cases the operator will need to reduce the

speed of operation. Typically the 8 to 10 miles per hour

window of operating speed will yield the most desirable

results.

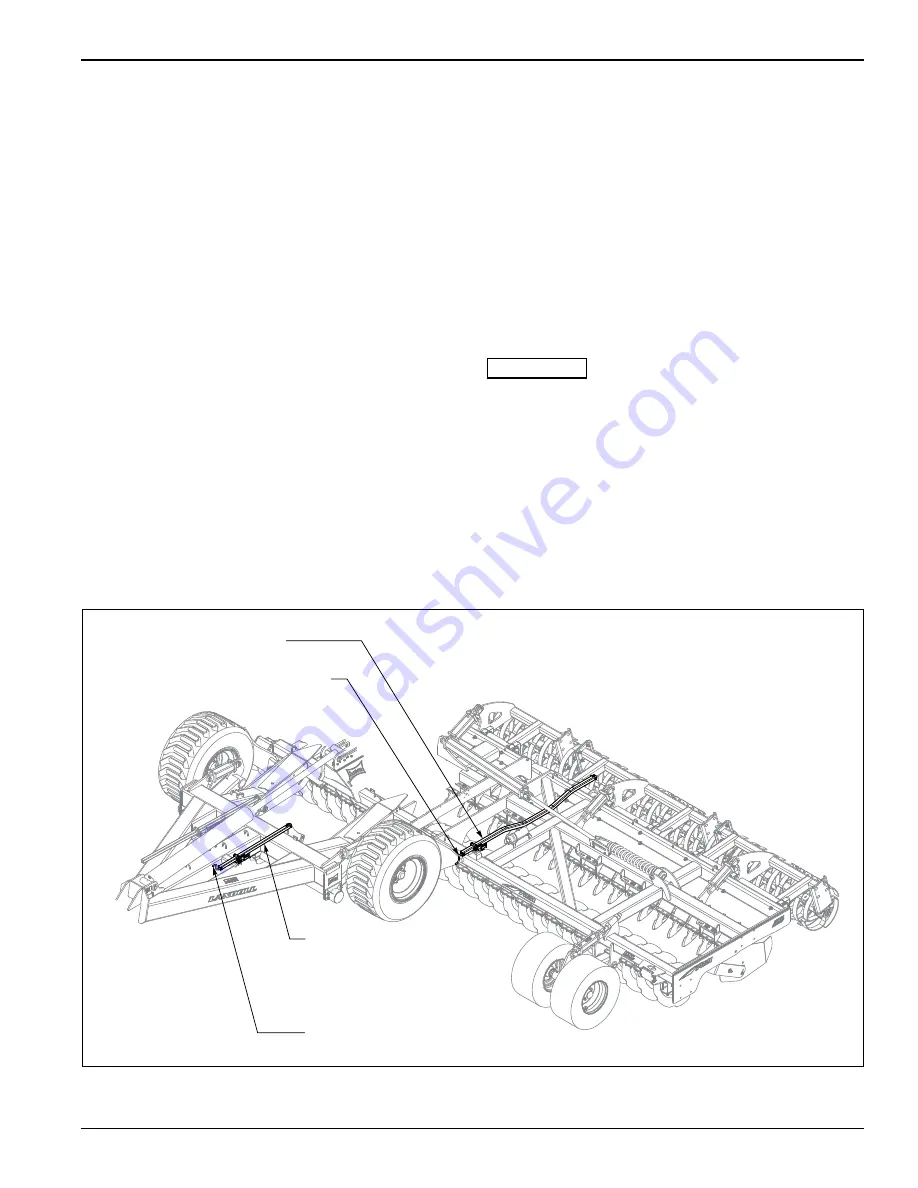

Operating Depths and

Adjustments

The HSL has two depth control gauges. One directly in

front of the front row of disc assemblies and one directly

behind the rear row of disc assemblies

• Both depth gauges are independently adjustable.

• Both have their deepest setting correlate to the

gauge cylinders being completely retracted but that is

where the correlation stops.

• Typically the front gauges will need to be set slightly

deeper than the rear because the front disc row is

doing more work than the rear is.

IMPORTANT

Do not be concerned with the front and rear gauges

being set differently for optimum operation!

The optimum working depth is considered to be 2 to

3-1/2 inches. The HSL can work on either side of this

range with good performance and results. Working depth

adjustments should always be made in conjunction with

considerations of operating speed. The HSL can bury as

much plant debris in a relatively shallow working depth as

conventional machines can at considerable deeper

operating depths because of the mixing action inherent to

the HSL if operating speed is not sacrificed.

Figure 4-6: Operating Depths and Adjustments

DEPTH CONTROL TUBE

DEPTH CONTROL TUBE

DEPTH ADJUSTMENT HANDLE

DEPTH ADJUSTMENT HANDLE

Summary of Contents for 7831

Page 2: ......

Page 4: ......

Page 12: ...2 4 F 801 1115 Edition STANDARD SPECIFICATIONS Table provided for general use NOTES...

Page 30: ...4 14 F 801 1115 Edition OPERATION AND MAINTENANCE Table provided for general use NOTES...

Page 34: ...5 4 F 801 1115 Edition TROUBLESHOOTING GUIDE Table provided for general use NOTES...

Page 35: ......