MAINTENANCE AND LUBRICATION

4-11

Figure 4-7: Brake Lining Wear

Spring Air Brake

Check for faulty units. Check the condensation holes on

the underside of the brake chambers to make sure they

are open. The spring brake has two brake chambers, a

service chamber and an emergency chamber or spring

chamber. Service brake chambers should be

disassembled and cleaned at 50,000 miles or yearly. The

diaphragm and any marginal parts should be replaced.

When replacing the service diaphragm, replace the

corresponding parts for the other chamber on the same

axle (to aid in even brake application and release).

Examine yoke pin for wear and replace as necessary.

The spring chamber should not be serviced. Replace

entire unit (both service and spring chamber) if spring

chamber becomes faulty.

WARNING

Replacing the Spring Air Brake

Unit

Caging the Power Spring in the

Spring Chamber

1.

Chock the trailer wheels.

2.

Remove dust cap from the rear of the spring brake

chamber

3.

Remove the release bolt from it’s holding brackets.

Insert it into the spring brake chamber until it can be

rotated and hooked into place.

DO NOT USE AN

IMPACT WRENCH TO CAGE THE SPRING

BRAKE!

4.

Turn the nut on the release bolt until the spring brake

is caged. This should be 2-1/4 to 2-1/2 inches of

release bolt extension.

5.

The brakes should now be released. Do not operate

loaded trailer with brake manually released.

Uncaging the Power Spring in

the Spring Chamber

1.

Chock the trailer wheels.

2.

Turn the nut on the release bolt until the spring is

released. Remove the release bolt and store it in its

brackets.

3.

Snap the dust cap back in place on the chamber.

Removal of Brake Unit

1.

Chock all tractor and trailer wheels and drain the air

system.

2.

Mark the brake chamber for proper air line port

alignment for reassembly.

3.

CAGE THE POWER SPRING following the steps

outlined in

“Caging the Power Spring in the Spring

4.

Disconnect the slack adjuster from the connecting

rod by removing the clevis pin

5.

Mark all air service lines for proper re-installation and

disconnect from the brake chamber.

6.

Remove the brake chamber from the axle brackets.

Installation of Brake Unit

1.

CAGE THE POWER SPRING following the steps

outlined in

“Caging the Power Spring in the Spring

The spring brake chamber employs a spring with

high forces. Service should not be attempted.

Serious injury or death may result.

Summary of Contents for 345F

Page 2: ......

Page 6: ......

Page 22: ...3 10 F 944 1017 Edition OPERATING INSTRUCTIONS Figure 3 4 Steps for Loading and Unloading...

Page 30: ...3 18 F 944 1017 Edition OPERATING INSTRUCTIONS Page Intentionally Blank...

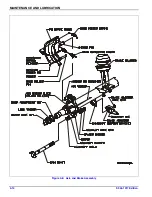

Page 44: ...4 14 F 944 1017 Edition MAINTENANCE AND LUBRICATION Figure 4 8 Axle and Brake Assembly...

Page 61: ......