Section 2: Tractor Hook-up & Unhook

SBD3596 & SBD35108 Snow Blowers 370-347M

4/9/21

20

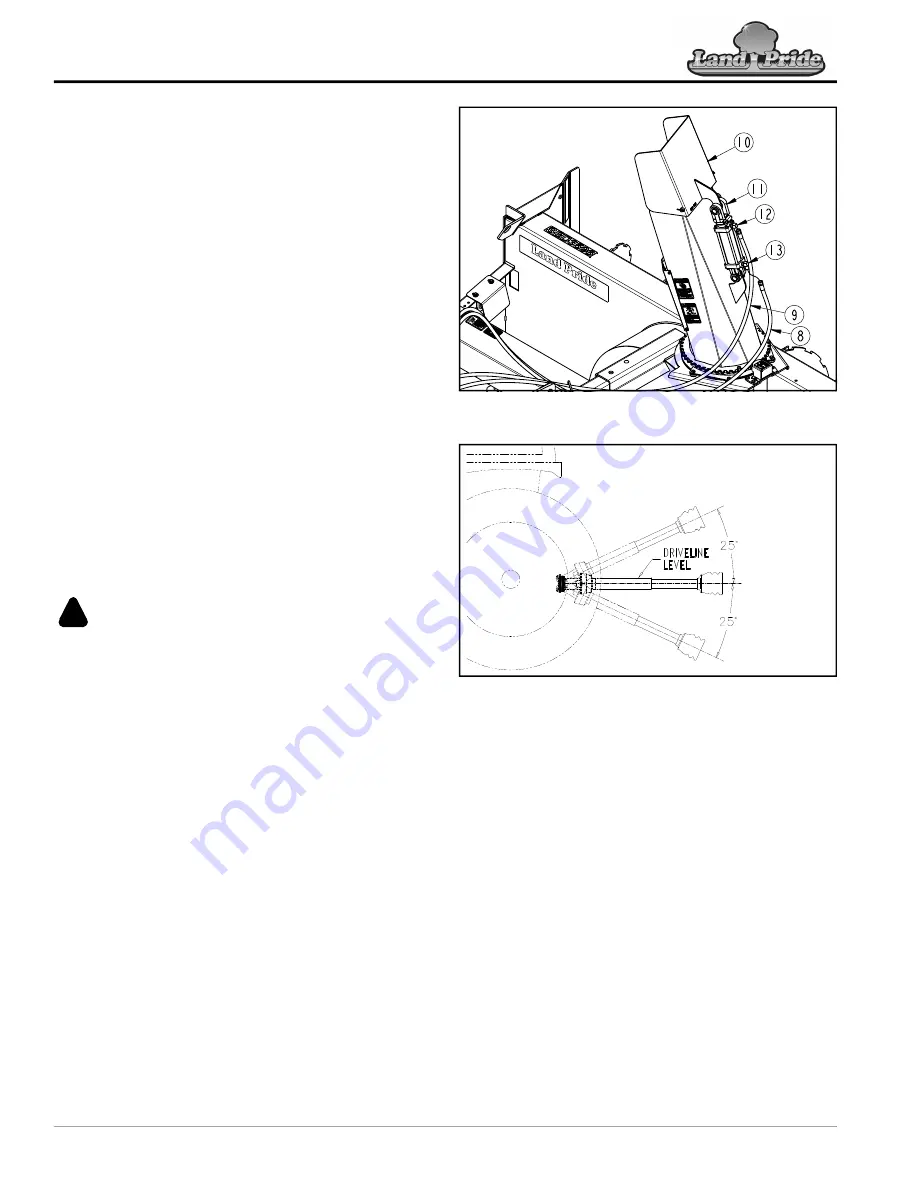

Refer to Figure 2-9:

2. Set tractor control lever in the non-float position.

3. It is best if chute deflector (#10) adjusts up when

pushing control lever on the tractor forward. If

deflector does not adjust in the direction desired,

switch quick disconnect couplings at the duplex

outlet.

4. Cycle hydraulic system by extending and retracting

cylinder (#11) several times to purge it of air.

5. Purge hydraulic system if hydraulic cylinder operates

unevenly after cycling it several times:

a. Loosen elbow fitting (#12) at the rod end of the

hydraulic cylinder.

b. Slowly retract and extend hydraulic cylinder until

all trapped air is purged from the cylinder and

hose.

c. Tighten elbow fitting (#12).

d. Loosen elbow fitting (#13) at the base end of

hydraulic cylinder (#11).

e. Slowly retract and extend hydraulic cylinder (#11)

until all trapped air is purged from the cylinder and

hydraulic hoses.

f. Tighten elbow fitting (#13).

Check Driveline Interference

Refer to Figure 2-10:

WARNING

!

To avoid serious injury or death:

A rotating driveline must not exceed an angle of 25 degrees up

or down, and never engage a driveline while at an angle

exceeding 25 degrees up or down. The driveline can break and

1. Start tractor and raise implement slightly off the

support blocks used to install the driveline. Drive

forward until the implement is clear of the supports.

2. Slowly and carefully lower and raise the implement to

ensure drawbar, tires, and other equipment on the

tractor do not contact the implement’s frame. If there

is an interference:

a. Back implement over the support blocks and

lower it onto the blocks.

b. Shut tractor down before dismounting. Refer to

c. Move or remove drawbar if it interferes with the

implement and make any other necessary

corrections.

d. Repeat steps 1-2 to verify the implement does not

interfere with the tractor.

3. Start tractor, raise implement fully up. Back

implement over the support blocks. Do not lower

implement onto the support blocks.

4. Without changing the 3-point lift height, shut tractor

down using

.

Purge Chute Hydraulic Cylinder

Figure 2-9

Maximum Driveline Movement During Operation

Figure 2-10

5. Check to make sure driveline does not exceed any of

the limits listed below:

•

Driveline does not exceed maximum length

recorded in step 3 under

•

Driveline angle does not exceed 25

o

above

horizontal.

6. If driveline exceeds maximum allowable length or 25

degrees up:

a. Adjust tractor 3-point lift limiter to the height that

will keep the driveline within the recommended

limits.

b. If the 3-point left lever does not have a lift height

limiter, make a mark with tape or other means to

indicate maximum lift height.

7.

Start tractor, raise implement slightly, and drive

forward enough to clear the support blocks.

8. Lower implement to the ground and shut tractor down

using

24872