1. INSTALLATION

1.1

RECEIVING

Each unit is completely tested under operating conditions and thoroughly inspected before

shipment. At the time of shipment, the carrier accepts the unit and any claim for damages must be

made with the carrier. Upon receiving units from the delivering carrier, carefully inspect carton for

visible indication(s) of damage. If damage(s) exists, have carrier note the same on the bill of lading

and file a claim with the carrier.

1.2

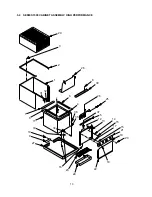

UNPACKING

A. Remove top portion of carton by lifting up.

B. Remove top inner carton pad and corners.

C. Remove accessory kit of loose parts from drip tray.

D. Lift Unit up by plywood shipping base and remove lower portion of carton.

E. Inspect unit for concealed damage(s) and if evident, notify delivering carrier and file a claim

against same.

F. Remove splash plate.

NOTE

Splash plate is located under unit on shipping base for Series 1500E models only.

G. Remove plywood shipping base from unit by moving unit so that one side is off the counter top

or table allowing access to screws on the bottom of the plywood shipping base.

NOTE

If unit is to be transported it is advisable to leave unit secured to plywood shipping base.

H. If Unit is to be installed with optional legs, assemble legs to unit by tilting unit.

DO NOT LAY

UNIT ON ITS SIDE OR BACK.

I.

Remove accessory kit of loose parts from drip tray.

1.3

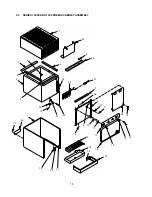

SELECTING A COUNTER LOCATION

A. The dispenser is designed to sit on a flat, supported surface capable of supporting a minimum

weight of 400 pounds (182 kg). It may be either counter or leg mounted. A template is

provided to cut and/or drill the necessary holes for mounting.

B. When the dispenser is to be permanently bolted to the counter top, seal dispenser base to

counter top with a bead of clear silicone caulk or sealant which provides a smooth and easily

cleanable bond to the counter.

NOTE

NSF listed units must be sealed to the counter or have four (4) inch legs installed.

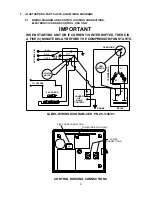

WARNING

FAILURE TO MAINTAIN THE PROPER AIR CLEARANCE WILL CAUSE THE COMPRESSOR TO

OVERHEAT AND WILL RESULT IN PREMATURE COMPRESSOR FAILURE.

C. Locate dispenser to allow approximately 15 inches (38 cm) of unobstructed space above and

six (6) inches (16 cm) behind the unit for proper air circulation. Air is drawn in through the back

grill and exhausted out of the top grill.

D. The bonnet may be removed by lifting bonnet upward.

1.4

CONNECTING THE DRAIN

A. Remove cup rest. Lift splash plate up and pull out and down on the bottom to remove.

B. Remove the drip tray from the unit and connect the drain tube to the drain fitting located on the

bottom. Secure drain tube with clamp provided in accessory kit.

C. Route the drain tube to a suitable drain and replace the unit’s drip tray.

1.5

FILLING UNIT WITH WATER

A. Remove the bonnet from the unit.

B. Remove the yellow plastic plug from the unit’s fill hole.

C. Fill the water bath compartment with water until it flows out of the overflow tube into the drip tray.

Use bottled drinking water where hard water problems exist.

Do not use distilled water with units

1