15

TROUBLE

CAUSE

REMEDY

Water only dispensed; no syrup;

or syrup only dispensed, no water

1.

Water or syrup shutoff on mounting block

not fully open.

2.

Improper or inadequate water or syrup

flow.

3. BIB supply too far from dispenser.

4.

CO

2

pressure too low.

5. Stalled or inoperative BIB pump

6. Kinked line.

1.

Open shutoff fully.

2. Remove valve from mounting block, open

shutoffs slightly and check water and

syrup flow. If no flow, check dispenser for

freeze-up or other problems. Ensure BIB

connection is engaged.

3. Check that BIB supply is within six (6) feet

of the dispenser.

4.

Check the CO

2

pressure to the pump

manifold to ensure it is between 70 and 80

Psi (0.483 and 0.552 MPa).

5. Check CO

2

pressure and/or replace pump.

6. Remove kink or replace line.

Valve will not shut off.

1. Cup lever may be sticking or binding.

2. Switch not actuating freely.

3. Solenoid armature not returning to bottom

position.

1. Correct or replace lever.

2. Check switch for free actuation.

3. Replace defective armature or spring.

Excessive foaming.

1. Incoming water or syrup temperature too

high.

2. CO

2

pressure too high.

3.

Water flow rate too high.

4. Nozzle and diffuser not installed.

5.

Nozzle and diffuser not clean.

6. Air in BIB lines.

7.

Poor quality ice.

8. High beverage temperature.

1. Correct prior to dispenser. Consider larger

dispenser or pre-cooler.

2. Adjust CO

2

pressure downward, but not

less than 70 Psi.

3. Re-adjust and reset ratio. Refer to “Adjust

Water Flow Rate & Syrup/Water Ratio”

Section.

4.

Remove and reinstall properly.

5. Remove and clean.

6. Bleed air from BIB lines.

7.

Check quality of ice used in drink.

8. Check refrigeration system.

Water continually overflows from

water bath into drip tray.

1. Loose water connection(s).

2.

Flare seal washer leaks.

3.

Faulty water coil.

1. Tighten water connections.

2.

Replace flare seal washer.

3. Replace water coil.

Warm drinks.

1. Dispenser was recently installed.

2.

Restricted airflow.

3. Dispenser connected to hot water supply.

4.

Condenser fan motor not working.

5. Dirty condenser, air vents clogged.

6. Dispenser capacity exceeded.

1. It may take up to 5 hours, after install, to

reach the desired temperature.

2. Check clearances around sides, top, and

inlet of unit. Remove objects blocking

airflow through grill.

3. Switch to cold water supply.

4.

Replace condenser fan motor.

5. Clean condenser and air vents of any

blockage.

6. Add pre-cooler or replace with larger

dispenser.

Summary of Contents for Delta-600 R-290

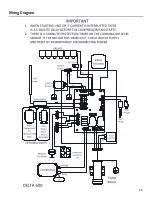

Page 23: ...23 Wiring Diagram...