PAGE 8

Do not plug the transformer into the receptacle yet. Make sure inlet and outlet valves are to their closed positions. If using

optional bypass, place in bypass position. Turn on main water supply. Open a cold water faucet. This will clear the line

of any debris (solder, pipe dope, etc.) that may be in the line. Let water run at faucet for a couple minutes, or until clear.

Turn off faucet. Now plug the transformer into a 120 volt receptacle (be certain the receptacle is uninterrupted). Within 5

seconds the control display and buttons will illuminate and the time of day screen will appear.

• Press and hold the

REGEN

button for approximately 5 seconds until the motor starts.

• Wait until display reads

BACKWASH

and numbers start counting down. (7-LX125CTAIR and 7-LX125IMAIR models

will have an

AIR RELEASE

cycle for 5 seconds then

BACKWASH

will appear.)

If using optional bypass

SLOWLY

turn bypass valve to

DIAGNOSTIC

position (

See figure 3 on page 4

) or slowly open

inlet valve to allow water to slowly enter filter.

Mineral is dry, and filling to quickly with water will result in the mineral plugging the drain line and valve

assembly. Some minerals such as carbon and Filter Ag should not be backwashed immediately for extended

periods of time. These minerals need to soak in water for a 24-hour period before backwashing at full flow. Flow

water to drain very slowly, increasing the flow until the water runs clear.

FOR 7-LX125CTAIR, 7-LX125IMAIR MODELS-

Momentarily press

REGEN

again. Display will read REGENERANT DRAW DN;

allow this cycle to complete

. This allows an

air pocket to form for the filter to function properly. Control will automatically advance to the FILTERING position. Open the

outlet valve of the filter, or if using optional bypass place to

NORMAL OPERATION MODE

(

see figure 1 on page 4

).

FOR ALL OTHER FILTERS-

When water is flowing steadily to drain without the presence of air, momentarily press

REGEN

again. Display will read

RINSE

. Open the outlet valve of the filter, or if using optional bypass place to

NORMAL OPERATION MODE

(

see figure

1 on page 4

). Allow control to finish the

RINSE

cycle. Allow the control to automatically advance to the

FILTERING

position.

PLACING FILTER INTO SERVICE

GENERAL OPERATION

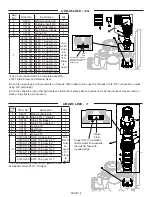

User Displays

When the system is in normal service mode, one of up to four available User Displays will be shown. Pressing

NEXT

will

alternate between the following displays:

• Current time of day

• Treated water flow rate

• Service contact name and phone number (if entered)

• Remaining days to regeneration (if Day Override is

programmed)

To clear the Service Call reminder

, press the

and

buttons simultaneously while the number and banner text

screen is displayed.

If the system has called for a backwash that will occur at the preset time of backwash, the words REGEN TODAY will

alternate with the header on the display.

Utilizing the control valve’s built-in water meter, a water drop flashes on the display when water is being treated (i.e. water

is flowing through the system).

Note: As an energy saving feature, the control will automatically turn off all SOLID BLUE or SOLID GREEN

display illumination and keypad illumination after about 5 minutes of the last keypad button push. Any further

keypad touch will cause the re-illumination of the display and keypad, and re-activate keypad control.