PAGE 12

6

2

4

3

5

1

7

8

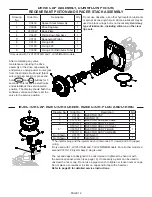

Drawing No.

Order No.

Description

Qty

1

V3176

INJECTOR CAP

1

2

V3152

O-RING 135

1

3

V3177-01

INJECTOR SCREEN CAGE

1

4

V3010-1Z

INJECTOR ASSY Z PLUG

1

5

†

V3010-1C INJECTOR ASSY C VIOLET

1

V3010-1F

INJECTOR ASSY F BLUE

V3010-1H INJECTOR ASSY H GREEN

Not Shown

V3170

O-RING 011

*

Not Shown

V3171

O-RING 013

*

* The injector plug and the injector each contain one 011 (lower) and 013 (upper)

o-ring.

†

Only used with 7-LX125CTAIR and 7-LX125IMAIR Models. For all other models, a

second V3010-1Z injector assy Z plug is used.

The nut and caps are designed to be unscrewed or tightened by hand or with

the service spanner wrench (see page 16). If necessary a pliers can be used to

unscrew the nut or cap. Do not use a pipe wrench to tighten or loosen nuts or caps.

Do not place a screwdriver in slots on caps and/or tap with a hammer.

Refer to page 20 for detailed service instructions.

1

2

3

4

5

INJECTOR CAP, INJECTOR SCREEN, INJEECTOR, PLUG AND O-RING

Drawing

No.

Order No.

Description

Qty

1

V3430

Spacer Stack Assembly

1

2

V3004

Drive Cap Assy

1

3

V3178LP

Back Plate

1

4

V3407

Piston Downflow Assy

1

5*

V3174

Regenerant Piston

1

6

V3135

O-ring 228

1

7

V3180

O-ring 337

1

8

V3358

O-ring 219 (Distributor Tube)

1

*Only used with 7-LX125CTAIR and 7-LX125IMAIR models.

DRIVE CAP ASSEMBLY, DOWNFLOW PISTON,

REGENERANT PISTON AND SPACER STACK ASSEMBLY

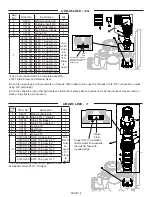

After completing any valve

maintenance involving the drive

assembly or the drive cap assembly

and pistons, unplug power source jack

from the printed circuit board (black

wire) and plug back in or press and

hold

NEXT

and

REGEN

buttons for 3

seconds. This resets the electronics

and establishes the service piston

position. The display should flash the

software version and then reset the

valve to the service position.

Do not use Vaseline, oils, other hydrocarbon lubricants

or spray silicone anywhere. A silicone lubricant may be

used on black o-rings but is not necessary.

Avoid any

type of lubricants, including silicone, on the clear

lip seals.

†