KYRA D 30 SI UNIT COND

A73022660

40

EN

ATTENTION

In case of a power failure, all settings

and displays remain stored.

Factory setting activation

The factory setting is activated by pressing and holding the control button and

deactivating the pump.

• Press the control button continuously for at least 4 seconds.

-

All LEDs

fl

ash for 1 second.

-

The LEDs of the last setting

fl

ash for 1 second.

On restarting the pump, it will work with the factory setting (delivery status).

Manual restart

•

When a blockage is detected, the pump

tries to restart automatically.

If the pump does not restart automatically:

•

Activate manual restart by pressing the

control button for 5 seconds, then release.

-

The restart function starts and lasts max.

10 minutes.

-

The LEDs

fl

ash clockwise one after the

other.

•

To stop, press the control button for 5 sec-

onds.

ATTENTION

After restarting, the LED indicator shows the

previously set pump values.

If it is not possible to eliminate a fault, con-

tact a system installer or Customer Service

System water characteristics

In case of water with hardness exceeding 25° Fr (1°F = 10ppm CaCO3), use suitably

treated water to prevent possible encrustations in the boiler. Treatment must not

reduce the hardness to values below 15°F (Decree 236/88 on water intended for

human consumption). However, treatment of the water is essential in case of very

large systems or frequent system water replenishment.

Frost protection system, antifreeze liquids, additives and inhibitors

A frost protection system activates the boiler in heating mode when the system

fl

ow temperature drops below 6°C. The device is not active if the power and/or

gas supply to the unit are disconnected. If necessary, the use of antifreeze liquids,

additives and inhibitors is allowed, only and exclusively if their manufacturer

provides a guarantee ensuring that the products are suitable for use and do not

cause damage to the boiler exchanger or to other components and/or materials of

the boiler and system. The use of antifreeze liquids, additives and generic inhibitors,

not speci

fi

cally suitable for use in heating systems compatible with the boiler and

system materials, is prohibited.

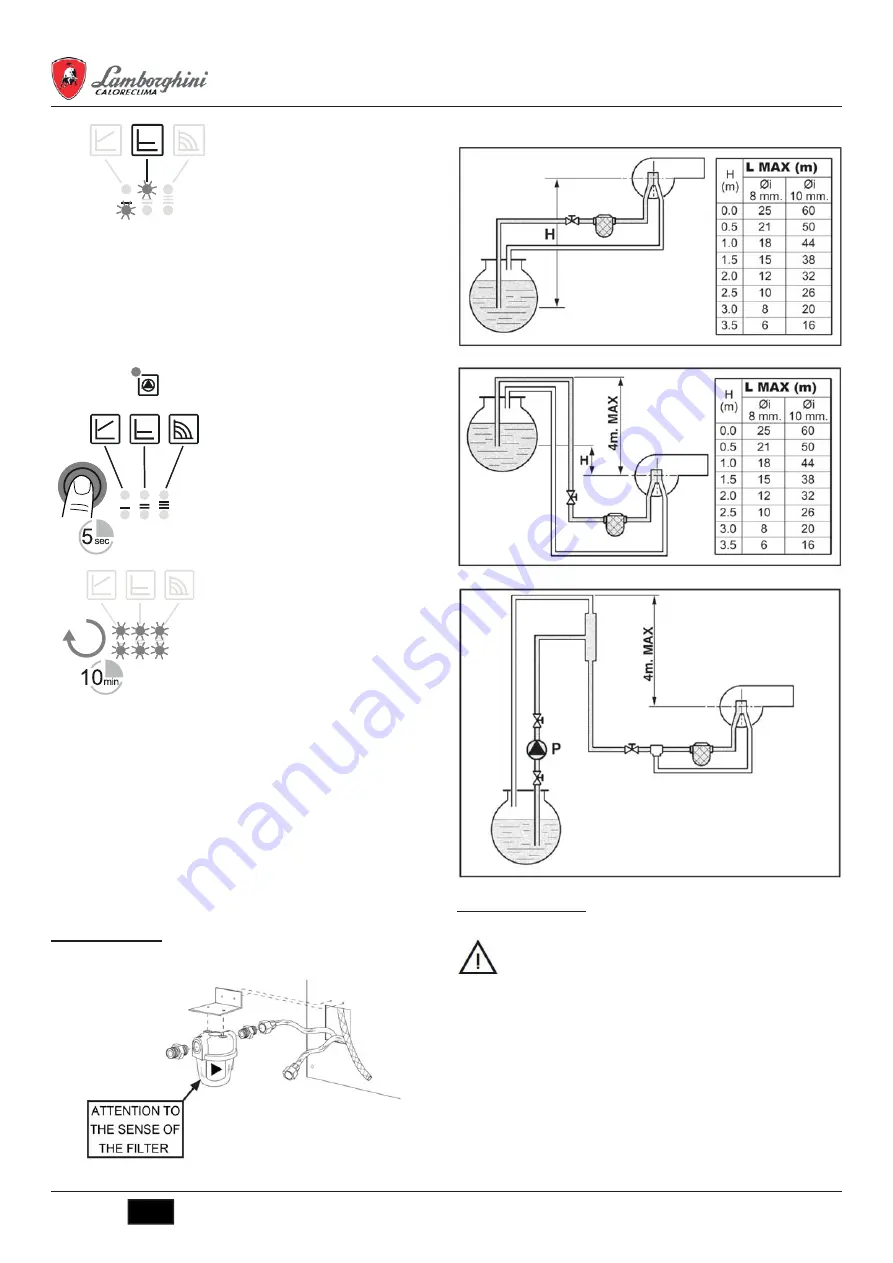

3.4 Burner connection

The burner is equipped with

fl

exible pipes and a

fi

lter for connection to the oil feed

line.Run the

fl

exible pipes out of the back and install the

fi

lter as indicated in

fi

g.20.

fi

g.18 - Fuel

fi

lter installation

The oil feed circuit must be made according to one of the following diagrams, with-

out exceeding the pipe lengths (LMAX) given in the table.

fi

g.19 -Suction feed

fi

g.20 - Siphon feed

fi

g.21 - Ring feed

3.5 Electrical connections

Connection to the electrical grid

The unit’s electrical safety is only guaranteed when correctly connected

to anef

fi

cient earthing system executed according to current safety

standards. Havethe ef

fi

ciency and suitability of the earthing system

checked by professionally quali

fi

ed personnel. The manufacturer is not

responsible for any damage caused by failure to earth the system. Also

make sure that the electrical system is adequate for the maximum power

absorbed by the unit, as speci

fi

ed on the boiler dataplate.

The boiler is prewired and provided with a Y-cable and plug for connection to the

electricity line. The connections to the grid must be made with a permanent connec-

tion andequipped with a bipolar switch whose contacts have a minimum opening of

at least 3mm, interposing fuses of max. 3A between the boiler and the line. It is im-

portant to respect the polarities (LINE: brown wire / NEUTRAL: blue wire / EARTH:

yellow-greenwire) in making connections to the electrical line. During installation or

when changingthe power cable, the earth wire must be left 2 cm longer than the

others.