19

NOTE:

Drawing pencil marks across the width of the top of the

calibrating board in several locations can make it easier

to determine when the entire surface has been planned.

7. Measure the thickness of the calibrating board with a caliper.

8. Loosen the two screws of the Thickness Scale pointer and adjust the

pointer (Fig. 7) until it corresponds to the measured thickness and

tighten the screws.

Thickness Gauge

The top of the planer is a thickness gauge. Material thickness can be

quickly identified by placing it on edge into the various gauges and

reading the corresponding measurement (Fig. 8).

Figure 8: Thickness Gauge

Stock Removal Gauge

Figure 9: Stock Removal Gauge

Thickness Gauges

Stock Removal

Gauge

Summary of Contents for PX12

Page 1: ...OWNERS S MANUAL PX12 Planer Quadtec I Cutterhead Lagunatools com...

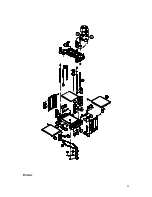

Page 29: ...29 EXPLODED VIEWS Cutterhead Drivetrain...

Page 30: ...30 Table Lift...

Page 31: ...31 Motor...

Page 32: ...32 Wiring Diagram PX12 PARTS LIST...

Page 38: ...38 021121...