MRX Multi-kit Demolition Tool Operation & Maintenance Manual | 23

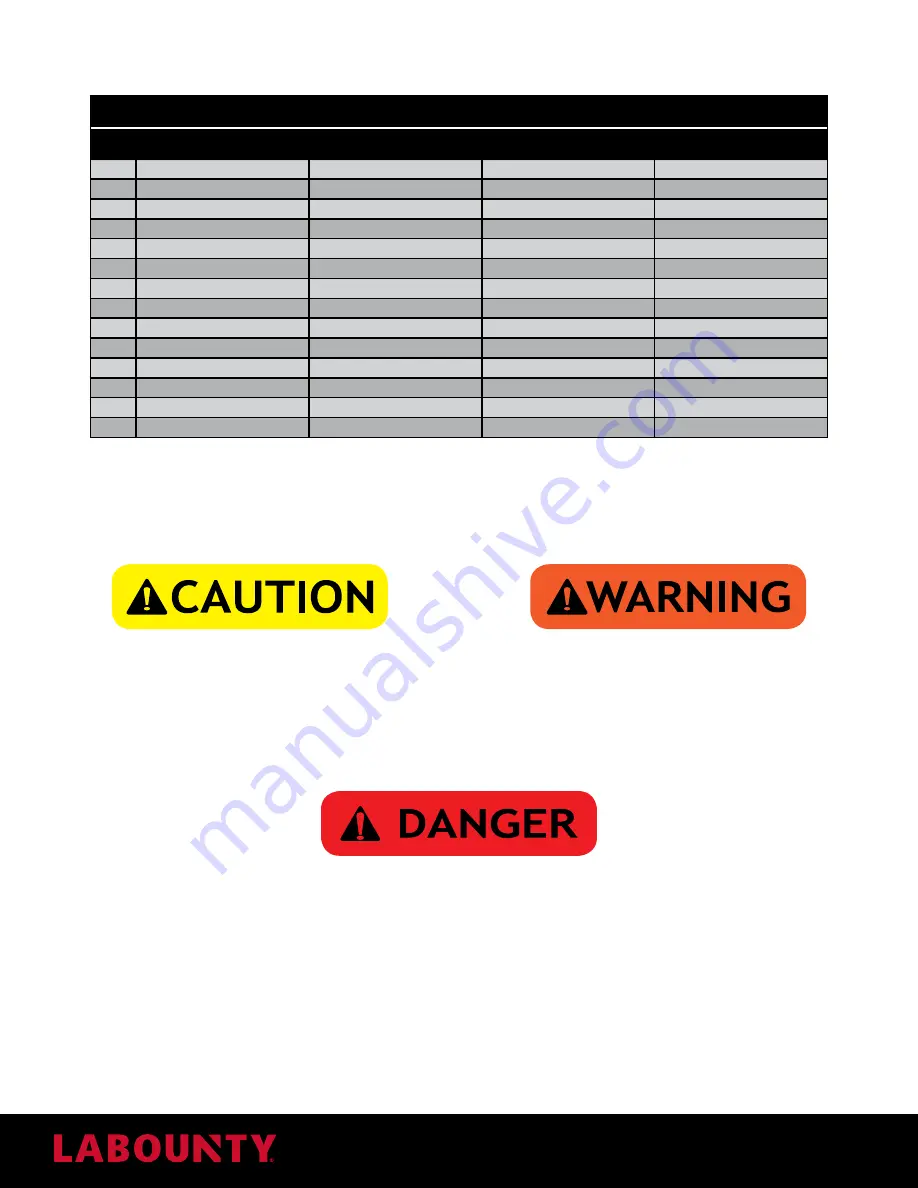

INSPECT / TORQUE BOLTS

General Fastener Torque Table

Size

6S

8.8 - (8G)

Class 10.9

Class 12.9

M5

4 Ft. Lbs. (5.10 Nm)

4 Ft. Lbs. (5.98 Nm)

6 Ft. Lbs. (8.5 Nm)

8 Ft. Lbs. (10.2 Nm)

M6

6 Ft. Lbs. (8.73 Nm)

8 Ft. Lbs. (10.3 Nm)

11 Ft. Lbs. (14.7 Nm)

13 Ft. Lbs. (17.6 Nm)

M8

16 Ft. Lbs. (21.58 Nm)

19 Ft. Lbs. (25.5 Nm)

26 Ft. Lbs. (35.3 Nm)

31 Ft. Lbs. (42 Nm)

M10

31 Ft. Lbs. (42.2 Nm)

37 Ft. Lbs. (50 Nm)

52 Ft. Lbs. (70.6 Nm)

63 Ft. Lbs. (85.5 Nm)

M12

54 Ft. Lbs. (73.6 Nm)

64 Ft. Lbs. (87.3 Nm)

90 Ft. Lbs. (122.6 Nm)

108 Ft. Lbs. (147 Nm)

M14

86 Ft. Lbs. (116.7Nm)

102 Ft. Lbs. (138.3 Nm)

143 Ft. Lbs. (194.2 Nm)

174 Ft. Lbs. (235.5 Nm)

M16

132 Ft. Lbs. (178.5 Nm)

156 Ft. Lbs. (210.9 Nm)

221 Ft. Lbs. (299.2 Nm)

264 Ft. Lbs. (358 Nm)

M18

181 Ft. Lbs. (245 Nm)

213 Ft. Lbs. (289.4 Nm)

304 Ft. Lbs. (412 Nm)

362 Ft. Lbs. (490.5 Nm)

M20

257 Ft. Lbs. (348.5 Nm)

304 Ft. Lbs. (412 Nm)

427 Ft. Lbs. (578.8 Nm)

514 Ft. Lbs. (696.5 Nm)

M22

347 Ft. Lbs. (471 Nm)

412 Ft. Lbs. (559.2 Nm)

579 Ft. Lbs. (784.8 Nm)

695 Ft. Lbs. (942 Nm)

M24

441 Ft. Lbs. (598.5 Nm)

525 Ft. Lbs. (711.2 Nm)

738 Ft. Lbs. (1000.5 Nm)

883 Ft. Lbs. (1197 Nm)

M27

655 Ft. Lbs. (888 Nm)

774 Ft. Lbs. (1049.7 Nm)

1092 Ft. Lbs. (1481 Nm)

1310 Ft. Lbs. (1776 Nm)

M30

890 Ft. Lbs. (1206.5 Nm)

1049 Ft. Lbs. (1422.4 Nm)

1483 Ft. Lbs. (2011 Nm)

1772 Ft. Lbs. (2403 Nm)

M33

1201 Ft. Lbs. (1628.5 Nm)

1425 Ft. Lbs. (1932.6 Nm)

2004 Ft. Lbs. (2717 Nm)

2410 Ft. Lbs. (3267 Nm)

BLADE MAINTENANCE

Before performing blade maintenance, place the attachment on the ground, so that the part being maintained is closest

to the ground. When performing maintenance on the upper jaw curl the attachment under the stick so that the upper

jaw is on the ground.

Wear personal protection equipment at all times. This

includes eye protection, hard hat, steel toe shoes,

leather gloves and hearing protection.

Blades are very heavy. Do not remove a blade if it’s not

supported. The blade may fall and cause injury.

CRACKER JAW

Measuring Blade Gap and Shimming

Note: Removing and handling blades can be hazardous if done incorrectly.

Stay at least 75 ft. (23 m) when moving.

1.

Cycle the tool until the upper jaw blade begins to overlap the lower jaw blade.

2.

Measure the blade gap. If the gap is larger than 0.4 mm, add shims between the guide blade and blade seat until the

gap is 0.4 mm - 0.4 mm.

Blade Rotation

Each cracker jaw blade has four edges. Each time you rotate the blade, use a different edge until all the edges are

worn to .25” radius.

Summary of Contents for MRX Series

Page 28: ...28 MRX Multi kit Demolition Tool Operation Maintenance Manual Wear Plates...

Page 30: ...30 MRX Multi kit Demolition Tool Operation Maintenance Manual...

Page 33: ......

Page 34: ......

Page 35: ......