Mighty Therm VW - PW Volume Water Heaters

Page 15

2F-11. Thermal Circulation of Hot Water

in Cold Water Supply Lines

Under certain circumstances, thermal circulation

will occur in the cold water pipe supplying the water to

the heating system. This happens in a multi-story

building when the cold water pipe rises from its

connection to the system. To correct the problem, a

check valve in the cold water line supplying the heater

will prevent thermal circulation, and a small expansion

tank will permit heated water to expand without

popping off the relief valve.

2G. Gas Supply and Piping

2G-1. General Instructions

Review the following instructions before

continuing the installation.

WARNING

The conversion of heaters from natural gas to

propane gas, or propane to natural, must be done

by a professional service technician. Laars provides

kits and detailed instructions for converting the

heater. Changing burner and/or pilot orifices is

prohibited. The installer must add and sign a gas

conversion tag when the conversion is made.

1.

Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1. In

Canada, the installation must be in accordance

with CAN1-B149.1 or .2 and all local codes that

apply.

2.

Check the rating plate to make sure the heater is

fitted for the type of gas being used. Laars

heaters are normally equipped to operate below a

2000 foot (609 m) altitude. Heaters equipped to

operate at higher altitudes have appropriate

stickers or tags attached.

3.

If a gas pressure regulator is required, the

installation must be in accordance with the latest

edition of ANSI Z223. In Canada, the installation

must be in accordance with CAN1-B149.1 or .2

and all local codes that apply.

4.

The figures in Table 5 should be used to size the

gas piping from the gas meter to the heater.

5.

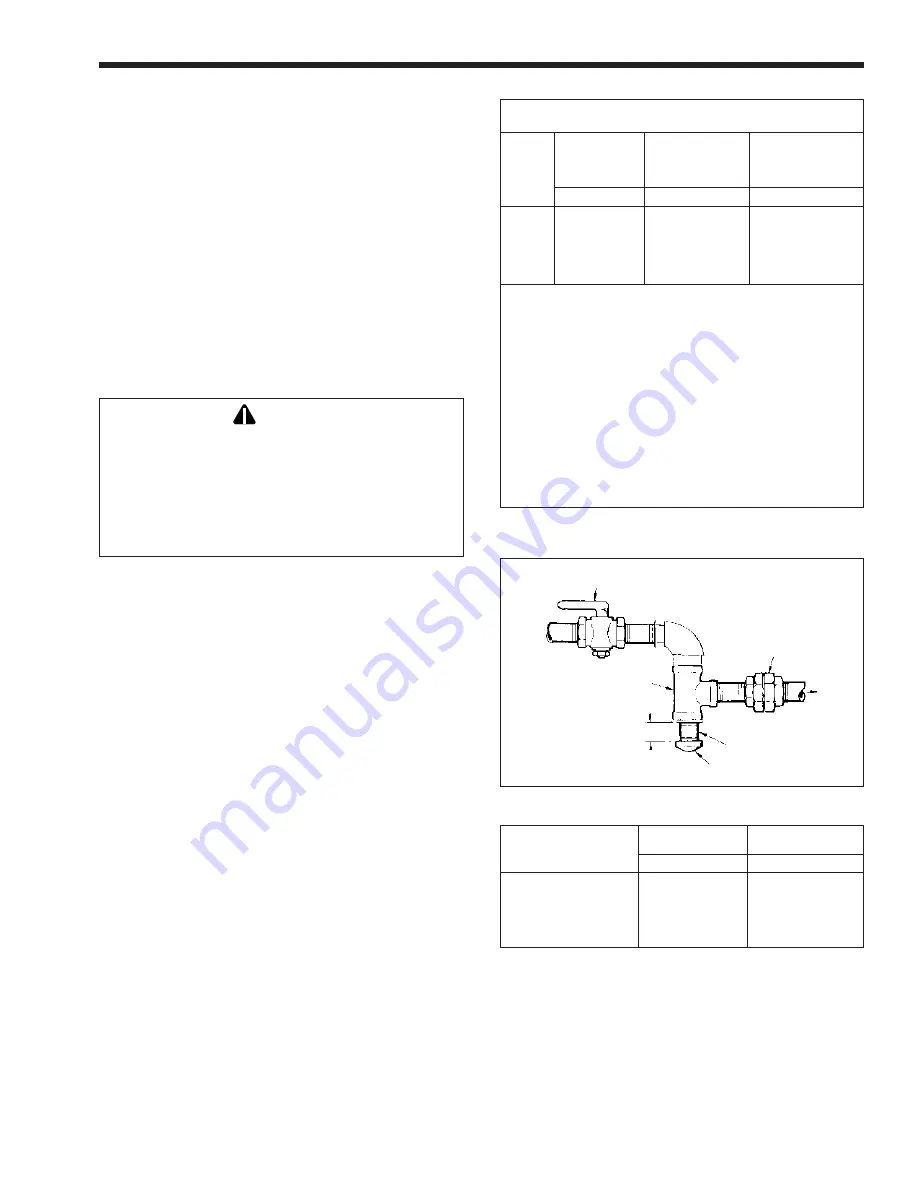

Install a sediment trap (drip leg) ahead of the gas

controls (see Figure 24 ). Fit the trap with a

threaded cap which can be removed for cleaning.

6.

Install a manual gas shutoff valve for service and

safety. Check the local codes.

7.

Disconnect the heater and its individual shutoff

valve from the supply gas system during pressure

test of the system at pressures higher than 1/2 psi

(3.4 kPa).

8.

Gas supply pressures to the heater are listed in

Table 6.

Figure 24. T-Fitting and sediment trap.

MANUAL SHUT-OFF

VALVE

GAS

SUPPLY

INLET

T-FITTING

3" (76 mm)

MIN.

UNION

NIPPLE

CAP

TO

BOILER

INLET

NOTE: The heater and all other gas appliances

sharing the heater gas supply line must be firing at

maximum capacity to properly measure the inlet

supply pressure. Low gas pressure could indicate

an under-sized gas meter and/or obstructed gas

supply line.

9.

Do not exceed the maximum inlet gas pressures

specified. Excessive pressure will result in

Distance from Gas Meter or Last Stage Regulator

0-100 feet

100-200 feet

200-300 feet

0-30 m

30-60 m

60-90 m

Boiler

Nat.

Nat.

Nat.

Size

in.

mm

in.

mm

in.

mm

175

1

25

1¼

32

1¼

32

250

1¼

32

1¼

32

1½

38

325

1¼

32

1½

38

1½

38

400

1¼

32

1½

38

2

51

Notes:

1. These numbers are for natural gas (0.65 Sp. Gr.) and

are based on

½

inch (13mm) water column pressure

drop. Check supply pressure with a manometer, and

local code requirements for variations. For liquefied

petroleum gas, reduce pipe diameter one size, but

maintain a

½

inch (13mm) minimum diameter.

2. Check supply pressure and local code requirements

before preceding with work.

3. Pipe fittings must be considered when determining gas

pipe sizing.

4. For propane gas: Reduce pipe diameter one size, but

maintain a

¾

inch (19mm) minimum diameter.

Table 5. Natural Gas and Propane,

Pipe Size Requirements.

Supply Pressure

Natural Gas

Propane Gas

Water Column

in.

mm

in.

mm

Minimum

6.5

165

11

279

See Rating Plate

Maximum

9

229

14

356

Table 6. Gas Supply Pressure Requirements.