15

MATERIALI /

MATERIALS /

MATERIAUX

LEGA AL-SI /

AL-SI ALLOY /

ALLIAGE AL-SI

GHISA G25 /

CAST IRON /

FONTE G25

ACC. AISI 304 /

STEEL AISI 304 /

ACIER AISI 304

ACCIAI LEGATI /

STEEL ALLOY

/ ALLIAGES ACIER

ACCIAI ALTA VEL. /

SUPER CUT STEEL

/ ACIERS GDE VIT.

ACCIAI DA BONIF. /

STEEL TO HARDEN

/ ACIERS trem.et rec.

FERRO (Fe37B) /

IRON (Fe37B)

/ FER (Fe37B)

GOMMA /

RUBBER

/ CAOUTCHOUC

PLASTICA /

PLASTIC

/ PLASTIQUE

BACHELITE /

BAKELITE

/ BAKELITE

CUSCINETTI /

BEARINGS /

ROULEMENTS

BRONZINE (B14) /

BUSHINGS (B14)

/ COUSSINETS (B14)

CAVI ELETTRICI /

ELECTRIC CABLE

/ CABLES ELECTR.

MOTORI /

MOTORS

/ MOTEURS

OLIO LUBRIF. /

LUBRICATING OIL

/ HUILE LUBRIF.

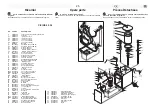

C/E INS 22 - C/E INS 32 - C/E INS 50

Per consentire all'utilizzatore della macchina

la scelta del dispositivo di protezione contro

le sovracorrenti (Art. 7.2.1 EN 60204-1) nel-

le schede tecniche sono specificati i dati ne-

cessari per scegliere il tipo, le caratteristi-

che, la corrente nominale e la regolazione

del suddetto dispositivo.

Avviare la mac-

china spingendo la leva a ginocchio

.

Appena avviata la macchina assicurarsi che

dall'ugello esca aria con pressione e non si

formi, invece, il vuoto.

In caso contrario (per motore trifase) cam-

biare il filo nero con quello marrone nella spi-

na di corrente, lasciando inalterata la posi-

zione del filo giallo-verde di collegamento a

terra.

Per fermare la macchina lasciare la leva a

ginocchio o premere il pulsante rosso

(n°110 foto E).

Demolizione

In conformità alla legislazione in vigo-

re e al fine di ridurre l'impatto ambientale del

rifiuto, è vietato smaltire la macchina come

rifiuto urbano. La macchina deve essere

smaltita presso gli appositi centri di raccolta

oppure essere riconsegnata al distributore

all'atto di acquisto di una nuova. Il simbolo

apposto sulla macchina indica l'obbligo della

raccolta separata dell'apparecchiatura. Lo

smaltimento abusivo e improprio della mac-

china e dei suoi componenti è soggetto a

sanzione come da normativa vigente. Ven-

gono elencati nella tabella riportata di segui-

to i principali materiali utilizzati nella costru-

zione della macchina.

The technical cards contain the data

necessary for choosing the type, features,

rated current and regulation for the above-

mentioned device allowing the user to

choose the protection device against

overcurrents (Art. 7.2.1 EN 60204-1).

Start

the machine by pushing the toggle-

joint lever.

As soon as the machine starts

make sure that air is discharged under

pressure through the nozzle and that no

vacuum forms. If that is not the case (for a

three-phase motor) swap the black wire with

the brown one in the electric plug, without

changing the position of the yellow-green

grounding wire.

To stop the machine release the toggle-

joint lever or press the red button

(n°110

photo E).

Demolition

Pursuant to prevailing law and

for the purpose of reducing waste

environmental impact, machine disposal

as urban waste is strictly forbidden. The

machine may only be forwarded to

special waste collection centres or

returned to the distributor when

purchasing a new machine. Machine

markings clearly identify it as separately

collectable waste. Improper or fraudulent

disposal of the machine or of any of its

parts is liable to criminal prosecution and

other provisions under law. The main

materials making up the machine are

listed below.

Pour permettre à l’utilisateur de la machine de

choisir le dispositif de protection contre

lessurintensités (Art. 7.2.1 EN 60204-1) dans

les fiches téchniques nous avons spécifié

les données necessaires pour choisir le

type, les charactéristiques, le courant nominal

et le reglage du dispositif susdit.

Mettre en

marche la machine en poussant le

levier à genou.

Dès que la machine est en

marche, s’assurer que du gicleur sorte de

l’air sous pression et que ne se forme pas de

vide.

Dans le cas contraire (moteur triphasé)

intervertir le fil noir et le fil marron dans la

prise de courant, en laissant inchangée la

position du fil jaune-vert de mise à la terre.

Pour arrêter la machine, relâcher le

levier à genou ou appuyer sur le bouton

rouge

(n°110 photo E).

Démolition

Conformément à la législation en

vigueur et afin de réduire l'impact

environnemental du déchet, il est défendu

d'éliminer la machine comme déchet

urbain. La machine doit être éliminée dans

les centres de collecte prévus à cet effet

ou bien remise au distributeur au moment

de l'achat d'une machine neuve. Le

symbole apposé sur la machine indique

l'obligation de la collecte séparée de

l'appareil. L'élimination abusive et impropre

de la machine et de ses composants est

passible de sanctions dans le cadre de la

réglementation en vigueur. On trouvera

dans le tableau ci-après la liste des

principaux matériaux utilisés pour la

fabrication de la machine.

Summary of Contents for C/E INS 22

Page 27: ...27...