EN

8

boiler to a predetermined level and will

shut off when full.

NOTE: It may be necessary to re-fill the water

reservoir during this process. Check to see if the

“Water Tank Empty” error message is present on

the display before continuing.

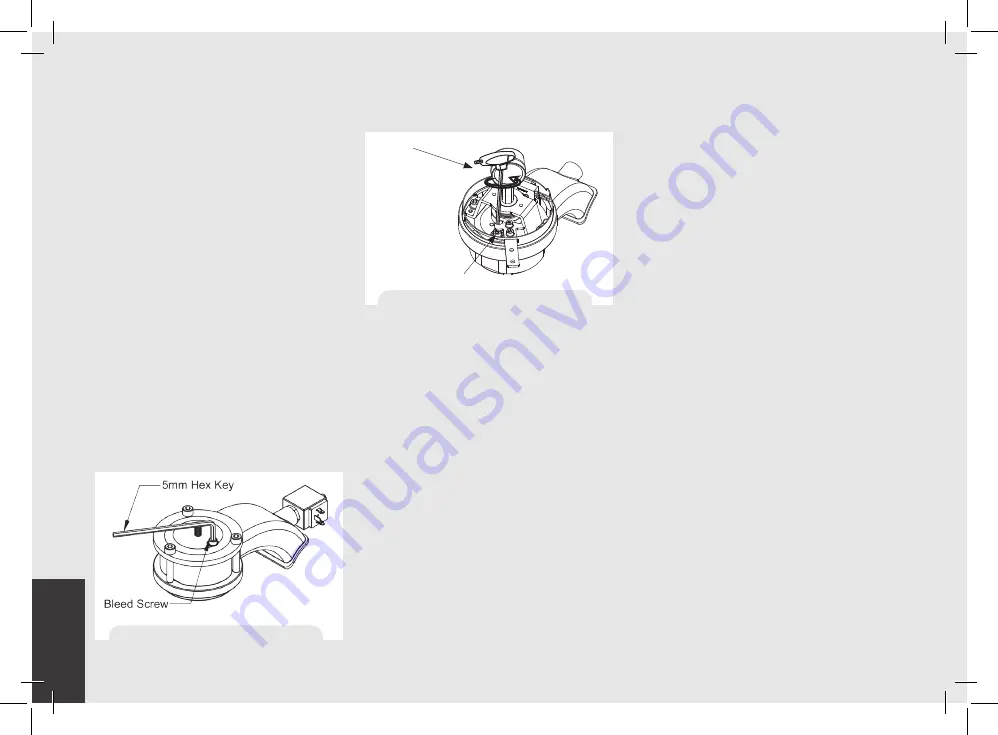

Coffee Boiler:

The water flows inside the

coffee boiler directly when the water pump

is activated. When the GS/3 is turned on

the electronics will activate the water

pump to fill both boilers. Since the inflow

of water will compress the air in the boiler it

will be necessary to remove or “bleed” the

air from the coffee boiler. All air must be

removed in order to completely “saturate”

the coffee boiler/group assembly. To

remove the air from the boiler (“bleed the

groups”) remove the group cover from the

top of the group head. Then loosen the

bleed screw (see picture) to allow air to

escape until water

flows from below the screw head. It may

be necessary to activate the brew process

by pressing button #5 (the

continuous button) to force the air out of

the group. Tighten the screw to stop the

water from flowing. Over-tightening can

cause damage to the sealing washer and

the group cap. If this sealing washer is

damaged replace washer with one included

in accessory kit. Once all air is removed

from the coffee boiler, reinstall the group

cover. For more detailed instruction please

refer the GS/3 Installation Guide.

NOTE: It may be necessary to re-fill the water

reservoir during this process. Check to see if the

“Water Tank Empty” error message is present on

the display before continuing.

4) Verify filling of Boilers.

The installation is now complete and the

espresso machine should be heating to the

operating temperatures.

Brewing after first installation

Once the first installation procedures are

finished, before proceeding with brewing

coffee, hot water and steam, please follow

these steps:

• Engage the portafilter by inserting it into

the group head and rotate the handle from

left to right. Once the portafilter is inserted

properly, you can press one of the brewing

buttons on the keypad to start the flow of

water through the portafilter (AV models)

or rotate the handle from left to right (MP

models). Brew water through the group for

at least two minutes.

• Being careful to avoid burns, turn

on steam wand for at least

one minute.

• Turn on the hot water valve for the time

necessary to allow at least 1 liter of water

to be brewed.

5) Waiting for the Espresso Machine to Heat to

Operating Temperature. During this time, the

pointer of the coffee boiler pressure gauge

may reach as high as 12 bar. This may

happen anytime that the heating element

is in the “on” condition. If the pressure

Figure 3a - “Bleed the Group AV”

Figure 3b - “Bleed the Group MP”

Bleed Screw

5 mm Hex Key