Installation and Operation Manual

8

Maximum Top Shelving Size Recommended: 22”

NOTE: The refrigerated air curtain is very important to the performance of this case. The load limit line (see operation

section) is the indicator of the inside edge of the air curtain and at no time should shelving, product, signs, debris,

etc., interfere with the air curtain.

NOTE: Temperature is measured in discharge air. Defrost frequency is at design conditions. Higher temperature or

humidity may require more defrosts per day and longer fail-safe times. These cases are not designed to operate in

environments where the ambient temperature does not exceed 75°F dry bulb temperature with 55% relative humidity.

NOTE: Off-cycle defrost is the recommended defrost type. Refer to www.kysorwarren.com for other electrical data

and information.

CAUTION: Failure to maintain store air conditions below 75°F dry bulb temperature with 55% relative humidity may

result in operational issues such as the following: increased thermal (Btuh) load, high product temperatures, coil

icing, product frosting, and external surface condensation.

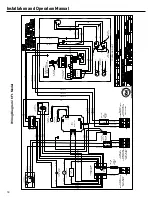

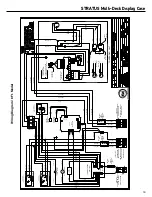

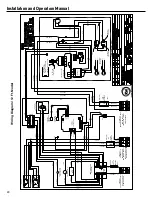

CAUTION: Failure to properly install electrical wiring and control wiring per wiring diagrams, defrost settings, and

temperature set-points may result in operational issues such as: increased thermal (Btuh) load, high product tem-

peratures, coil icing, product frosting, and external surface condensation.

Case Installation

These display cases are installed individually.

Preparation—Prepare the installation area as follows:

1.

Clean area where case is to be installed.

2.

Verify installation area is at least 15 feet from any outside entrances or heating and cooling outlets.

3. Verify at least 2 feet of distance between hot and cold cases.

4. Ensure floor loading will support the case and the case contents.

5. Ensure proper AC power is available. Refer to case AC input requirements located in the electrical connec

-

tions section of this manual.

6. Ensure location will allow connection to drain lines and the drain line, when installed, will meet the recom

-

mendations as set forth in the refrigeration piping and dehydration section of this manual.

7.

Ensure expansion valve in case is the proper valve for the type of refrigerant used at the installation site.

CAUTION: To prevent condensation on the end panels of cases, a minimum of 3.0 inches between walls or other

cases is required for airflow. If 3.0 inches is not possible, then the space between the cases must be completely

filled and sealed or an updraft fan kit must be installed to provide air circulation through the space.

Installation

The following instructions are provided for unpacking, moving, loading, and lifting the case prior to installation.

NOTE: READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING INSTALLATION.

Unpacking

WARNING! Use caution when removing the strapping in the following procedure because the shelves are very

heavy and could fall causing personal injury or equipment damage.

1. Remove all shipping tape from lamps and ensure that all lamp ends are snapped firmly in place.

2.

Ensure the evaporator cover is installed correctly with the deck pans installed.

3. Move the case into position, install, adjust superheat, and perform the operational checkout procedures

following the instructions within this manual.

CAUTION: Be careful not to damage the factory installed ends while moving the case. Use the case lift points on the

case to move it to the proper location.