- 26 -

CHECKING HAMMER KNIFE MOUNTING AXLES WEAR

Hammer knives must be checked each time before using the machine. They must systemati-

cally be checked after any impact to the machine.

Shredding quality, reliability of the machine and your safety depend on regular checking of these elements.

The hammer knives must be replaced in the following cases :

Damaged hammer knives :

Any impact to the machine can cause the hammer knives to warp or crack with the following consequences :

- Reduction in shredding quality

- Increase in vibrations bringing with it mechanical problems on the machine

- Partial or total breakage of the hammer knives with risk of projections.

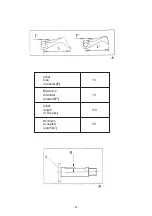

Worn hammer knives (fig. A) :

- The fixation hole diameter (F) should not be oval-shaped by more than 2 mm in relation to its original diameter.

- The length (L) of the hammer knife should not be less than 30 mm in comparison to its original length.

The mounting axle should be changed if (fig. B) :

- The thread is damaged. Also check the weld at the head of the fixation screw (S)

- The axle is worn down by more than 2 mm (H).

The self-locking nuts cannot be used more than twice.

Check the washers regularly.

Torque of M 16 nuts : 10 daNm / 75 ft.lbs.