77

PERIODIC SERVICE

B

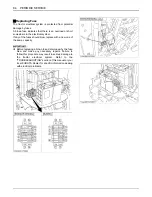

Checking Radiator Hose and Clamp

To avoid personal injury:

A

Be sure to stop the engine and remove the key

before checking radiator hose and clamp.

A

Allow engine and coolant to cool down

sufficiently before checking.

Check to see if radiator hoses are properly fixed every 200

hours of operation or 6 months, whichever comes first.

1. If hose clamps are loose or water leaks, tighten bands

securely.

2. Replace hoses and tighten hose clamps securely, if

radiator hoses are swollen, hardened or cracked.

Replace hoses and hose clamps every 2 years or earlier

if checked and found that hoses are swollen, hardened or

cracked.

C

Precaution at Overheating

Take the following actions in the event the coolant

temperature is nearly or more than the boiling point, what

is called "Overheating"

1. Park the tractor in a safe place and keep the engine

unloaded idling.

2. Don't stop the engine suddenly, but stop it after about

5 minutes of unloaded idling.

3. Keep yourself well away from the machine for further

10 minutes or while the steam blows out.

4. Check that there are no dangers such as burns. Get rid

of the causes of overheating according to the manual,

see "TROUBLESHOOTING" section, and then, start

again the engine.

B

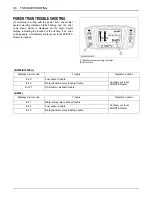

Checking Intake Air Line

1. Check to see that hoses and hose clamps are tight and

not damaged.

2. If hoses and clamps are found worn or damaged,

replace or repair them at once.

(1) Radiator hoses (2 hoses)

(2) Clamp bands (4 clamps)

(1) Hose

(2) Hose clamps

Summary of Contents for B2650

Page 2: ......

Page 17: ...7 SAFE OPERATION 7 DANGER WARNING AND CAUTION LABELS...

Page 18: ...SAFE OPERATION 8...

Page 19: ...9 SAFE OPERATION...