7

3

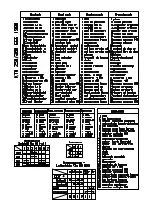

TROUBLE

Engine has not enough power

Engine revs not high and run-

ning with four stroke cycle

High rpm misfiring

Engine spluters into the carbu-

retor

Engine overheating

Emission of white smoke

(steam)

Excessive oil escapes from

transmission breather tube

All switched on lamps blown

out

CAUSE

Reed paddles tensionless or damaged,

surface of reed valve housing damaged

Wear

Electronical ignition timing faulty

Carburetor overflows if level adjust too

high, float needle seating is dirty or

enlarged

Loose carburetor jets

Incorrect heat range spark plug or

low quality spark plug

Incorrect or faulty spark plug connector

Loose, corroded or non conductive

ignition socket connector

Lack of fuel

Spark plug with incorrect heat value

(Ignition by incandescence)

Engine takes air out of control

Insufficient liquid in cooling system

Cooling system not or insufficiently

bleeded

Radiator fins clogged

Frothing in cooling system

Pinched or kinked water hoses

Incorrect ignition timing because of

loose stator screws

Incorrect dimension ,,X“

Cylinder head or O-ring of cylinder

head gasket leaks

Excessive oil quantity in transmission

Water pump shaft seal ring or right-

hand crankshaft seal ring defect

Silicon O-rings of control roller or of

control flap leaks

Voltage regulator faulty

REMEDY

Replace reed paddles or reed valve housing

Overhaul engine

Have ignition system checked

Clean carburetor, if necessary replace float needle and adjust level

Tighten jets

Refer to technical data section

Test and/or replace spark plug connectors correct type

Check and seal with silicon

Clean fuel pipes, examine tank aeration and clean

Fit correct spark plug

Check intake flange and carburettor if firmly setted

Top up coolant and bleed cooling system check cooling system for

leaks

Bleed cooling system (see operating instructions)

Clean radiatar fins with water jet

Renew coolant using branded anti-freeze/anti-corrosive

Replace with correct routed hoses

Readjust to correct ignition timing specifications, secure screws pro-

perly with Loctite 242

Measure and adjust to correct specification

Check cylinder head, replace O-ring

Correct transmission oil level

Replace shaft seal ring and change gear oil, check coolant

Replace O-rings

Control connections of voltage regulator. Check voltage regulator

Summary of Contents for 250 1998

Page 9: ... Notices ...

Page 39: ... Notices ...

Page 43: ... Notices ...

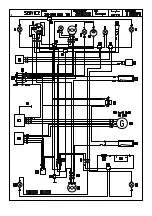

Page 44: ...7 1 7 0 Trouble shooting Cap Component Component unit Page 7 1 Trouble shooting 7 2 ...

Page 47: ... Notices ...

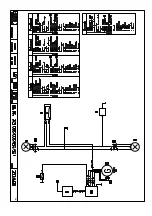

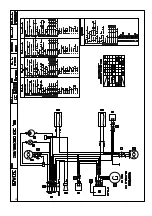

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......