4

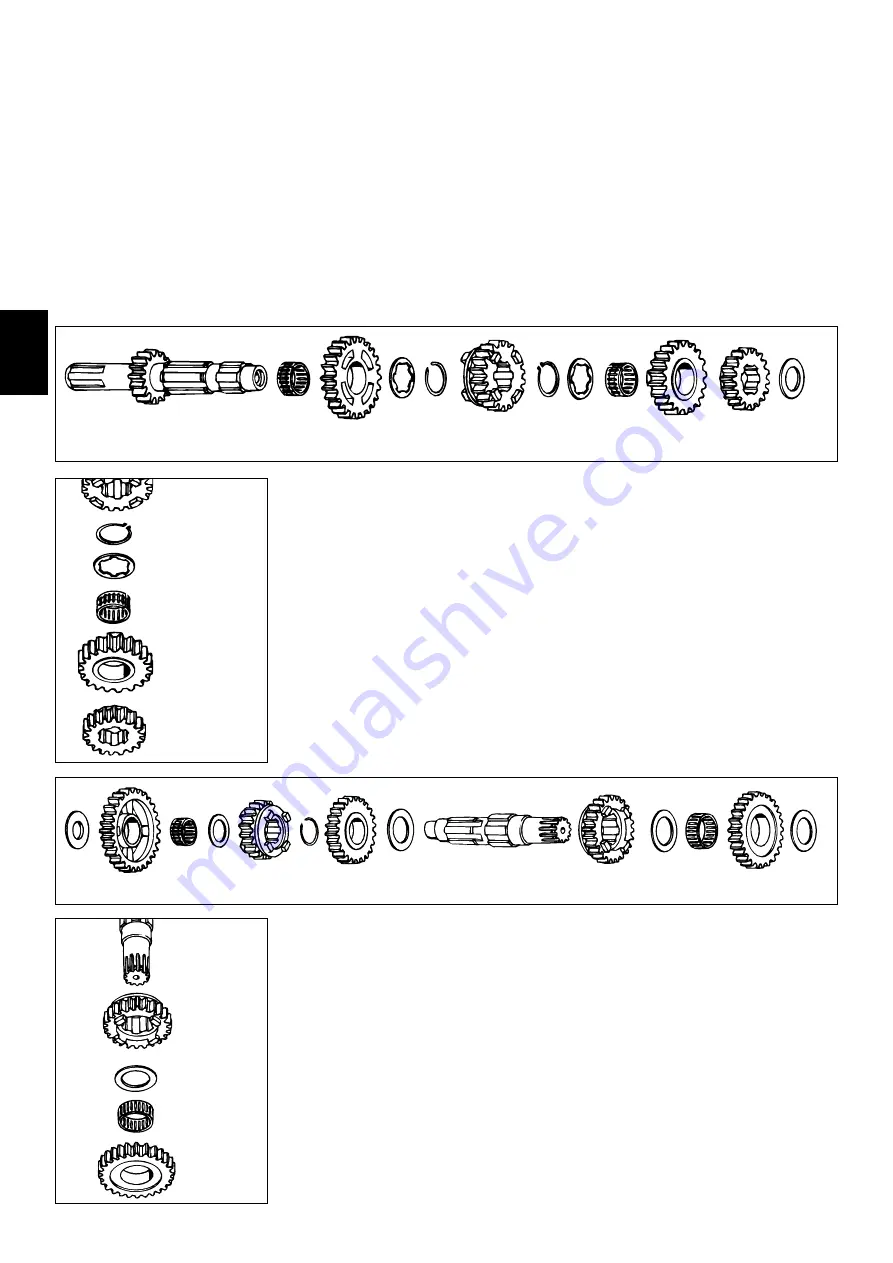

4.15.1 Assembly mainshaft

– Fix mainshaft in vice with toothed end upwards (use covered clamps).

– Oil all parts before assembly.

– Mount the split needle cage

1

on mainshaft, push 5

th

idler gear

2

over it with collar downwards.

– Place internally toothed stop disc

3

in position and mount circlip (25x1.64 mm)

4

with sharp

edge upwards.

– Place 3

rd

sliding gear

5

in position with shift groove downwards, mount circlip

6

with sharp edge

downwards and internally toothed stop disc

3

.

– Mount the split needle cage

1

, 4

th

idler gear

7

with shift dogs downwards 2

nd

gear

8

with collar

downwards and stop disc

9

(20.2x32x1.5 mm).

– Finally check all gears for easy running.

4.15 Transmission

Secure mainshaft or countershaft in the vice (using soft jaw-covers).

Remove gears and check the following for wear:

A

) N

EEDLE BEARING

B

) M

AINSHAFT AND COUNTERSHAFT PIVOT POINTS INCLUDING IDLER GEARS

C

) S

HIFT DOGS AND GEAR WHEELS

D

) T

OOTH FACES OF ALL GEARS

E

) T

OOTH PROFILE OF MAINSHAFT AND COUNTERSHAFT AND CORRESPONDENDING GEARS

F

) E

ASY OPERATION OF GEAR

-

CHANGE

Carefully clean components and replace damaged components.

NOTE

: A

LWAYS PLACE CIRCLIPS WITH SHARP EDGE FACING THE COMPONENTS SECURED

,

ENSURING THAT THEY ARE

NOT OVEREXPANDED

(

USE SPECIAL PLIERS

). C

HECK THAT AFTER ANY REPAIR OF THE TRANSMISSION

,

CIRCLIPS

SHOULD AXIALLY NOT MOVE MORE THAN

0,2

MM

(0.006

IN

)

AND MUST NOT SEIZE BETWEEN STOP DISCS

.

4.15.2 Assemble countershaft

– Fix countershaft in vice with toothed end (use covered clamps).

– Oil all parts before assembly.

– Push stop disc

1

(25,2x40x1,5 mm) onto countershaft.

– Mount 3

rd

idler gear

3

with shift dog recesses upwards and circlip (25x4 mm)

4

with sharp edge

upwards.

– Mount 5

th

sliding gear

5

with shift groove downwards, stop disc

6

(24,2x36x1,5 mm), needle

cage

2

, 1

st

free gear

7

with shift dog recesses downwards and stop disc

8

(17,2x34x1,5-2 mm)

with collar upwards on the countershaft.

– Remove countershaft from vice and fix again with toothed end upwards.

– Mount 4

th

sliding gear

9

with shift dog upwards, stop disc

bk

(28,2x42x1,5 mm), needle cage

bl

, 2

nd

idler gear

bm

with shift dog recesses downwards and stop disc

bn

(25,2x40x1,5 mm).

– Finally check all gears for easy running.

91

0

1

1

1

2

1

2

3

4

5

6

3

1

7

8

9

3

1

9

10

11

12

13

4

5

6

2

7

8

Summary of Contents for 250 1998

Page 9: ... Notices ...

Page 39: ... Notices ...

Page 43: ... Notices ...

Page 44: ...7 1 7 0 Trouble shooting Cap Component Component unit Page 7 1 Trouble shooting 7 2 ...

Page 47: ... Notices ...

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......