6

Meganorm

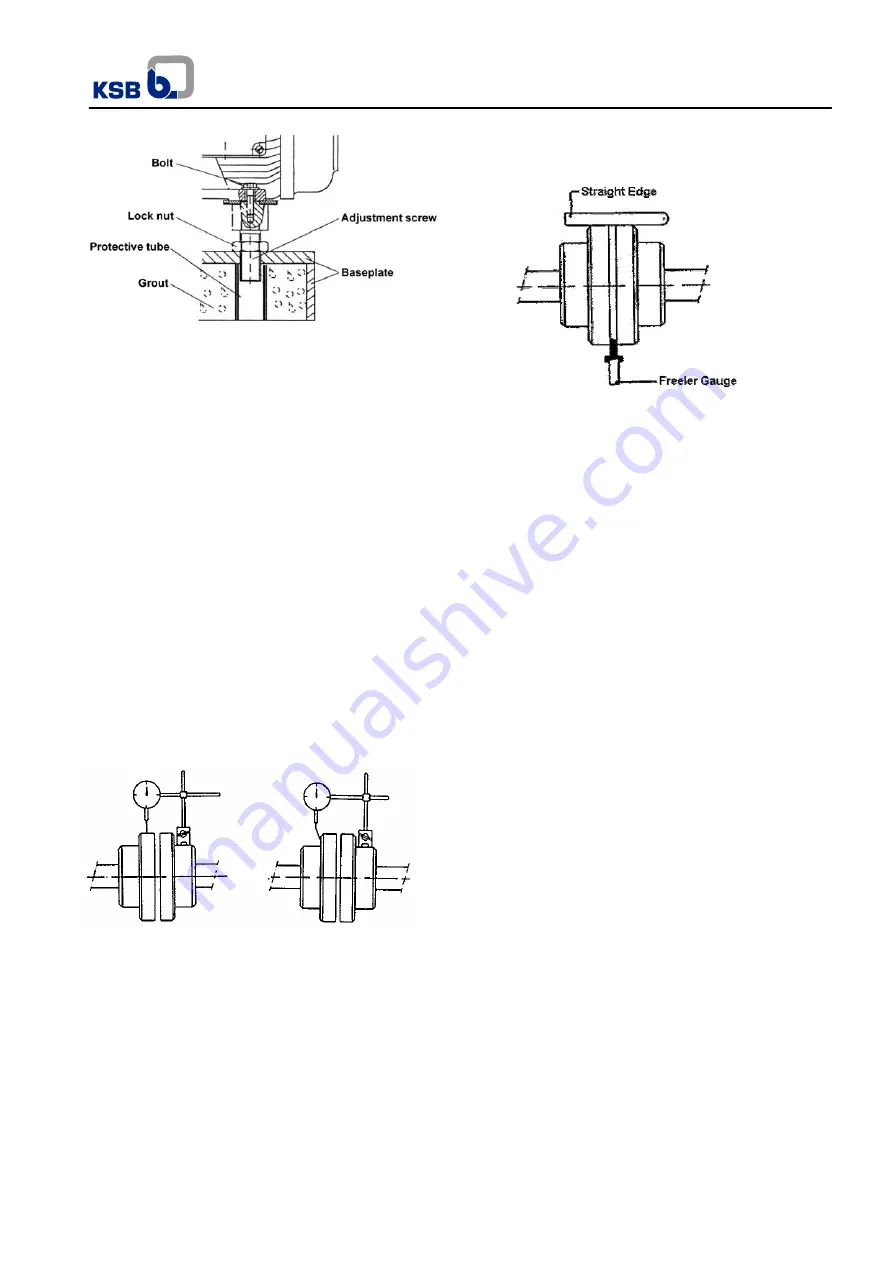

Fig. 6b – Grouting inside the baseplates of adjusting screw

type

9.4 Coupling alignment

The useful life of the rotating assembly and its operation free

of irregular vibrations will rely on the perfect alignment

between the pump and the driver.

The alignment performed at the factory must be rechecked

due to the fact that during transportation and handling, the

motor-pump assembly is subjected to deformations, which

may affect the initial alignment.

After the complete set of the grout, perform the alignment, if

possible, with the suction and discharge pipe lines already

connected.

This alignment should be performed with the help of a dial

indicator for the control of the radial and axial displacements.

Fix the button of the instrument to the periphery of one the

coupling halves, adjust the position of the feeler

perpendicular to the periphery of the other half of the

coupling. Move the dial to zero and move manually the

coupling half in which the instrument button is fixed, making

the dial complete a 360 degrees turn. Please see Fig.7.

The same procedure should be performed to control the axial

displacement. Please see Fig.8.

Fig. 7 Fig.8

Radial control Axial control

To correct the alignment, loosen the driver bolts and move

driver laterally or insert shims to adjust height as required.

Axial and radial alignments should remain within a tolerance

of 0.1 mm with the pump and driver set screws tighten

securely.

If there is no dial indicator available, use a straight edge

placed across the two rims of the sleeve coupling. To control

axially use a feeler gauge. Please see Fig. 9. Observe the

sleeve coupling hub clearance specified by manufacturer.

Fig. 9 – Alignment with straight edge and feeler gauge

9.4.1 Motors without adjustment bolts

For the alignment correction, loosen the bolts from the drive

replacing them laterally, or insert shims to correct the height

as required.

9.4.2 Motors with adjustment bolts

To realign the coupling, first loose the four drive bolts, as well

as the lock nuts. Turn the adjustment bolt by hand or with a

tool until the coupling alignment is correct. Retighten the bolts

and respective nuts.

9.5 Suction pipeline – Recommendations

To install the suction piping follow these instructions:

a) Connect the suction piping to the pump only after the

complete hardening of the grout in the base plate.

b) The suction piping should be as straight and short as

possible – reducing pressure losses - and totally air tight,

preventing any air leaks.

c) In order to be free of air pockets, the horizontal section of

the suction piping, when negative, should be installed with

gradual rise slope. When positive, the horizontal section

of the pipeline should be installed with a gradual rise

slope to the suction tank.

d) The nominal diameter of the pump suction flange does not

determine the suction pipe nominal diameter. To calculate

the ideal diameter as a reference, the liquid velocity can

be defined between 3.2 ft/s and 6.5 ft/s (1 and 2 m/s).

e) If it were necessary to use a reduction, it should be

eccentric, mounted with its taper facing downwards, so

that the reduction upper generatrix stays in a horizontal

position coincident with the pump generatrix, so as to

prevent air pockets.