6 Commissioning/Start-up/Shutdown

17 of 30

KWT51

1974.95/01-EN

6.2.2 Selecting the quench liquid / buffer fluid

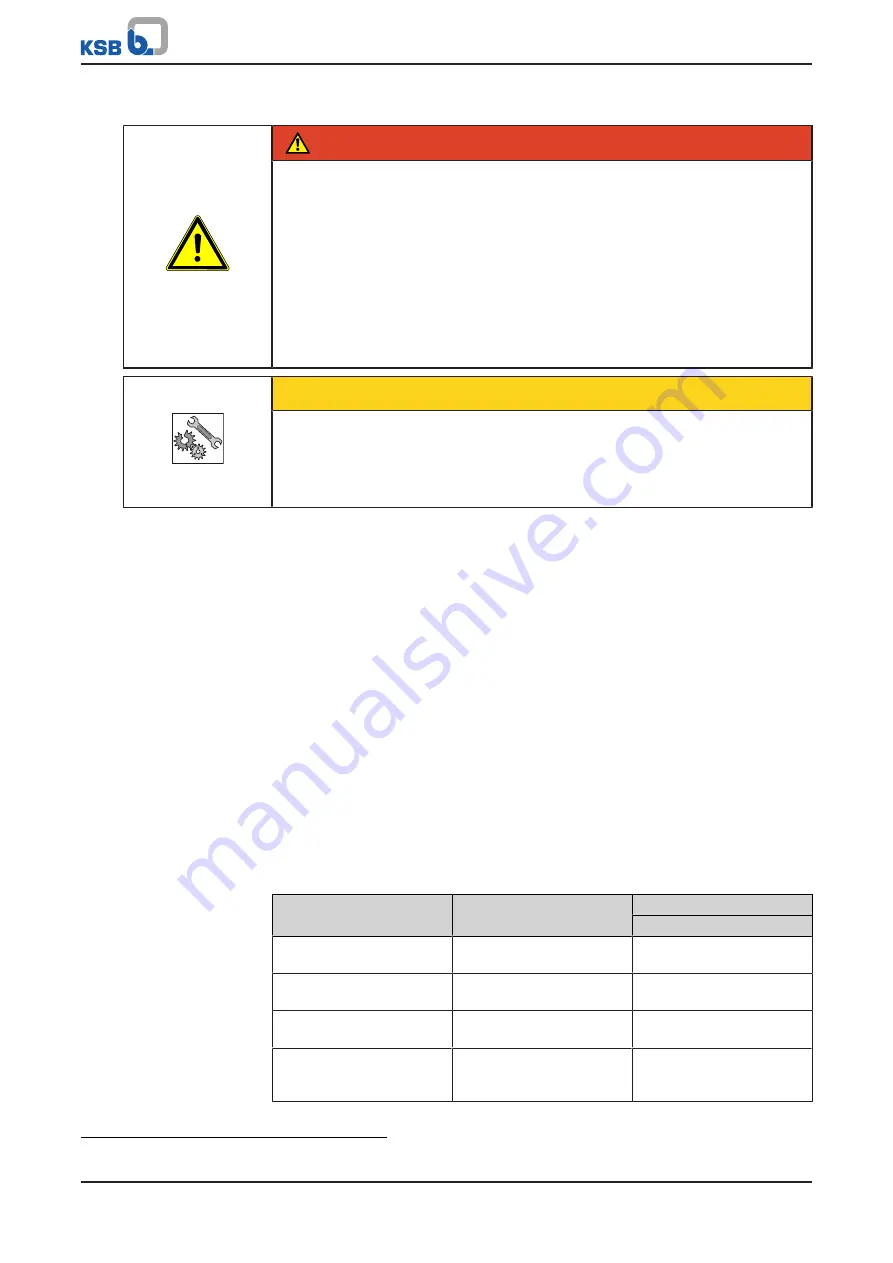

DANGER

Contact with toxic, flammable, explosive or hot quench liquid / barrier fluid

Risk of injury, e.g. chemical burns on the skin and in the eyes, poisoning and burns!

▷

Observe the relevant safety instructions, e.g. safety data sheets, for the

handling of hazardous substances (wear safety goggles, protective gloves,

protective clothing, etc. if required).

▷

Wear personal protective equipment (e.g. safety goggles, protective gloves,

protective clothing, etc).

▷

Collect and properly dispose of the quench liquid / buffer fluid.

▷

Remove any quench liquid / buffer fluid residues from the KSB quench system

and flush the system thoroughly.

CAUTION

Use of non-approved fluids

Interaction between quench liquid / buffer fluid and fluid handled!

▷

Only use the fluids listed in the order documentation.

▷

If in doubt, contact the manufacturer of the fluids.

When selecting the buffer fluid

1)

observe the following:

▪

Additives which inhibit wear and/or oxidation are often found in commercial

turbine oils and can lead to deposits on the seal faces.

▪

Use a clean buffer fluid

1)

not containing any foreign matter.

▪

The buffer fluid

1)

should have flow characteristics which prevent the formation of

deposits or residues.

▪

The buffer fluid

1)

should prevent the formation of ice and keep salts dissolved.

▪

The buffer fluid

1)

should prevent any contact between the fluid handled and

atmosphere or reduce the absorption of humidity by the fluid handled.

▪

It should be resistant to ageing.

▪

It should be stable at the applicable operating temperature and operating

pressure.

▪

Avoid fluids susceptible to evaporation, hardening and foaming.

▪

Ensure compatibility with the fluid handled. If the inboard mechanical seal fails,

the two fluids may come into contact with each other.

▪

Buffer fluid escaping to

1)

atmosphere must be acceptable.

Table 5:

Preferred buffer fluid

1)

Buffer fluid

1)

Function of the buffer

fluid

1)

Operating temperature

[°C]

Ethylene glycol

Preventing the formation

of ice

-40 to +100

Light oils (viscosity 2 – 3°E

at 50 °C)

Absorbing leakage or

lubricating the seal faces

-10 to +120

Water

Diluting salts contained in

leakage

10 to 80

Water + ethylene glycol

Diluting salts contained in

leakage and preventing the

formation of ice

-20 to 100° C (70 %/30 %)

-35 to 110° C (50 %/50 %)

1

Quench liquid / buffer fluid