9 Trouble-shooting

32 of 36

BOA-Control/ BOA‑Control IMS

9 Trouble-shooting

WARNING

Improper remedial work on the valve

Risk of injury!

▷

For any work performed in order to remedy faults on the valve observe the

relevant information given in this operating manual and/or the product

literature provided by the accessories manufacturers.

If problems occur that are not described in the following table, consultation with the

KSB customer service is required.

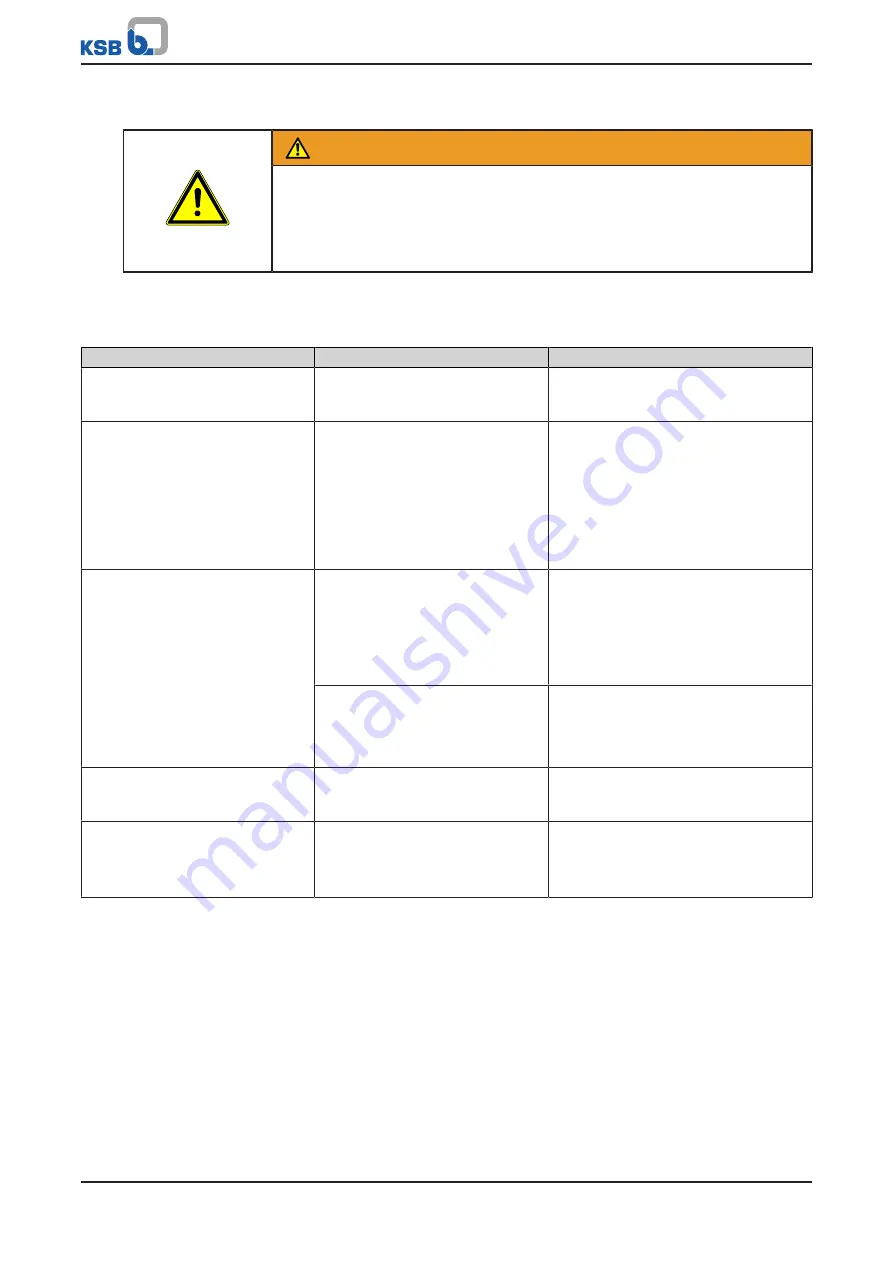

Table 17:

Trouble-shooting

Problem

Possible cause

Remedy

Leakage at the seat/disc interface of

BOA-Control/BOA-Control IMS

DN 15 to 200

Rework not possible.

Replace valve.

Leakage at the seat/disc interface of

BOA-Control IMS DN 250 to 350

1. Dismantle the bonnet/cover bolting

(902/920/901).

2. Rework the seating faces of valve

disc and body using a suitable re-

seating tool.

3. Continue re-seating until the

seating faces exhibit a consistently

smooth and even ring.

Leakage at the bonnet gasket of

BOA-Control IMS DN 250 to 350

Unevenly tightened bonnet/cover

bolts

1. Undo the bonnet/cover bolting

(902/920 or 901).

2. Replace the joint ring (411).

3. Re-tighten the bonnet/cover

bolting (902/920 or 901) as specified

in the manual.

Defective bonnet/cover gasket

1. Dismantle the bonnet/cover bolting

(902/920/901).

2. Clean the sealing surfaces.

3. Replace the joint ring (411).

Leakage at the stem seal of BOA-

Control/BOA-Control IMS DN 15 to

200

Rework not possible.

Replace valve.

Leakage at the stem seal of BOA-

Control IMS DN 250 to 350

1. Tighten the stuffing box screws

(45-6) firmly to prevent leakage.

2. Replace the complete upper valve

section immediately.