2

Installation and operating instruction ALTOFLUX M900 and 3080 K

Contents

System description ...................................................................................................................... 2

Product liability and warranty ..................................................................................................... 2

Standards and approvals ............................................................................................................. 3

Items included with supply........................................................................................................... 3

Handling . ...................................................................................................................................... 3

1

Important information for installation: PLEASE NOTE !....................................................4

2

Suggestions for installation ..................................................................................................5

3

Instrument nameplate ............................................................................................................6

4

Flowmeter versions................................................................................................................6

5

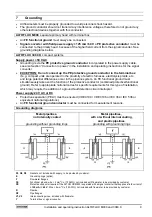

Installation in the pipeline .....................................................................................................7

6

Torques ...................................................................................................................................8

7

Grounding...............................................................................................................................9

8

Replacement of the separate primary head .......................................................................10

9

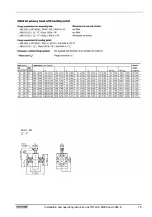

Technical data ......................................................................................................................12

10

Dimensions and weights .....................................................................................................14

11

Limits.....................................................................................................................................17

If you need to return flowmeters for testing or repair to KROHNE ........................................ 19

System description

ALTOFLUX electromagnetic flowmeters are precision measuring instruments designed for the

linear flow measurement of process liquids.

The process liquids must be electrically conductive:

≥

20

µ

S/cm

The

full-scale range

Q

100%

can be set as a function of the

meter size

:

ALTOFLUX M900:

DN 10 - 300 /

3

/

8

” - 12”

Q

100%

= 0.1 - 3050 m

3

/hr = 0.37 – 13 440 US GPM

ALTOFLUX 3080 K:

DN 10 - 300 /

3

/

8

” - 12”

Q

100%

= 0.1 - 3050 m

3

/hr = 0.37 – 13 440 US GPM

This is equivalent to a flow velocity of 0.3 - 12 m/s, or 1 – 40 ft/s.

Product liability and warranty

ALTOFLUX electromagnetic flowmeters are designed solely for measuring the volumetric

flowrate of electrically conductive, liquid process products.

Flowmeters with ALTOFLUX primary heads are not certified for use in hazardous locations.

Other flowmeters series are available for such applications.

Responsibility as to suitability and intended use of these electromagnetic flowmeters rests solely

with the operator.

Improper installation and operation of the flowmeters (systems) may lead to loss of warranty.

In addition, the ”General conditions of sale” forming the basis of the purchase contract are

applicable.

If ALTOFLUX flowmeters need to be returned to Krohne, please note the information given on

the last-but-one page of this manual. Krohne regret that they cannot repair or check your

flowmeter(s) unless accompanied by the completed form sheet.

Summary of Contents for ALTOFLUX 3080 K

Page 11: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 11 Notes...

Page 12: ...12 Installation and operating instruction ALTOFLUX M900 and 3080 K 9 Technical data...

Page 13: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 13...

Page 14: ...14 Installation and operating instruction ALTOFLUX M900 and 3080 K 10 Dimensions and weights...

Page 15: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 15...

Page 16: ...16 Installation and operating instruction ALTOFLUX M900 and 3080 K...

Page 17: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 17 11 Limits...

Page 18: ...18 Installation and operating instruction ALTOFLUX M900 and 3080 K Notes...