Installation and operating instruction ALTOFLUX M900 and 3080 K

19

If you need to return flowmeters for testing or repair to KROHNE

Your electromagnetic flowmeter

•

has been carefully manufactured and

tested by a company with ISO 9001

certification

•

and volumetrically calibrated in one of the

world’s most accurate test rigs.

If installed and operated in accordance with

these operating instructions, your flowmeter

will rarely present any problems.

Should you nevertheless need to return a

flowmeter for checkout or repair, please pay

strict attention to the following points:

Due to statutory regulations concerning

protection of the environment and the health

and safety of our personnel, Krohne may only

handle, test and repair returned flowmeters

that have been in contact with liquids if it is

possible to do so without risk to personnel

and environment. This means that Krohne

can only service your flowmeter if it is

accompanied by a certificate in line with the

following model confirming that the flowmeter is

safe to handle.

If the flowmeter has been operated with toxic,

caustic, flammable or water-endangering

liquids, you are kindly requested

•

to check and ensure, if necessary by rinsing

or neutralizing, that all cavities in the

flowmeter are free from suchdangerous

substances.

(Directions on how you can find out whether

the primary head has to be opened and then

flushed out or neutralized are obtainable

from Krohne on request.)

•

to enclose a certificate with the flowmeter

confirming that the flowmeter is safe to

handle and stating the liquid used.

KROHNE regret that they cannot service your

flowmeter unless accompanied by such a

certificate.

S P E C I M E N certificate

Company: ……………………………………….. Address: ……………………………………………

Department: …………………………………….. Name: ………………………………………………

Tel. No.: ………………………………………….

The enclosed electromagnetic flowmeter

Type: …………………………………………….. KROHNE Order No. or Series No ………………

has been operated with the following liquid: ……………………………………………………………..

Because this liquid is

water-endangering * / toxic * / caustic * / flammable *

we have

– checked that all cavities in the flowmeter are free from such substances *

– flushed out and neutralized all cavities in the flowmeter *

(* delete if not applicable)

We confirm that there is no risk to man or environment through any residual liquid contained in

this flowmeter.

Date: ………………………….. Signature: ……………………………………………………………..

Company stamp:

Summary of Contents for ALTOFLUX 3080 K

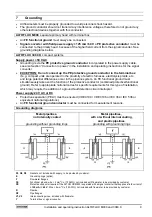

Page 11: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 11 Notes...

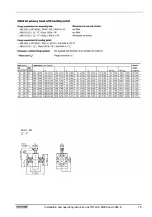

Page 12: ...12 Installation and operating instruction ALTOFLUX M900 and 3080 K 9 Technical data...

Page 13: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 13...

Page 14: ...14 Installation and operating instruction ALTOFLUX M900 and 3080 K 10 Dimensions and weights...

Page 15: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 15...

Page 16: ...16 Installation and operating instruction ALTOFLUX M900 and 3080 K...

Page 17: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 17 11 Limits...

Page 18: ...18 Installation and operating instruction ALTOFLUX M900 and 3080 K Notes...