8

Installation and operating instruction ALTOFLUX M900 and 3080 K

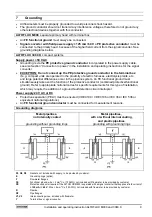

6 Torques

•

Tighten stud bolts uniformly in diagonally opposite sequence, see table for number and type.

•

Column A, Torques for Teflon

®

-PTFE liner.

•

Column B, Torques for liner made of Polypropylene and hard rubber.

•

10 Nm ~ 1.0 kpm ~ 7.23 ft

×

lbf

Meter Pres- Bolts

Max.

torque

Meter

Body

Bolts

Max. torque

size sure

Nm (ft

×

lbf)

size

pressure

Nm (ft

×

lbf)

rating

rating

DN mm

PN

A B

inch psig

A

B

10

40

4 x M 12

7.6

(5.5) 4.6

(3.3)

3

/

8

580

4 x

1

/

2

"

3.5

(2.5)

3.6

(2.6)

15

40

4 x M 12

9.3

(6.7) 5.7

(4.1)

1

/

2

580

4 x

1

/

2

"

3.5

(2.5)

3.6

(2.6)

20

40

4 x M 12

16

(11.6) 9.6

(6.9)

3

/

4

580

4 x

1

/

2

"

4.8

(3.5)

4.8

(3.5)

25

40

4 x M 12

22

(15.9) 11

(8.0)

1

580

4 x

1

/

2

"

6.7

(4.8)

4.4

(3.2)

32

40

4 x M 16

37

(26.8) 19

(13.0)

1

1

/

2

580

4 x

1

/

2

"

13

(9.4)

12

(8.7)

40

40

4 x M 16

43

(31.1) 25

(18.1)

2

580

4 x

5

/

8

"

24

(17.4)

23

(16.6)

50

40

4 x M 16

55

(39.8) 31

(22.4)

3

360

4 x

5

/

8

"

43

(31.1)

39

(28.2)

65

16

4 x M 16

51

(36.9) 42

(30.4)

4

230

8 x

5

/

8

"

34

(24.6)

31

(22.4)

65

40

8 x M 16

38

(27.5) 21

(15.2)

6

230

8 x

3

/

4

"

61

(44.1)

51

(36.9)

80

25

8 x M 16

47

(34.0) 25

(18.1)

8

145

8 x

3

/

4

"

86

(62.2)

69

(49.9)

100

16

8 x M 16

39

(28.2) 30

(21.7)

10 145 12

x

7

/

8

"

97

(70.2)

79

(57.1)

125

16

8 x M 16

53

(38.3) 40

(28.9)

12 145 12

x

7

/

8

"

119

(86.1)

104

(75.2)

150

16

8 x M 20

68

(49.2) 47

(34.0)

200

10

8 x M 20

84

(60.7) 68

(49.2)

200

16

12 x M 20

68

(49.2) 45

(32.5)

250

10

12 x M 20

78

(56.4) 65

(47.0)

250

16

12 x M 24

116

(83.9) 78

(56.4)

300

10

12 x M 20

88

(63.7) 76

(54.9)

Note: Process pressure must not exceed ANSI

300

16

12 x M 24

144

(104.2) 105

(75.9)

flange rating. Refer to ANSI Standard B 16.5.

Teflon

®

is registered trademark of Du Pont

Summary of Contents for ALTOFLUX 3080 K

Page 11: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 11 Notes...

Page 12: ...12 Installation and operating instruction ALTOFLUX M900 and 3080 K 9 Technical data...

Page 13: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 13...

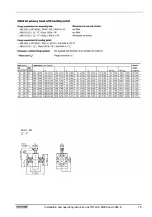

Page 14: ...14 Installation and operating instruction ALTOFLUX M900 and 3080 K 10 Dimensions and weights...

Page 15: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 15...

Page 16: ...16 Installation and operating instruction ALTOFLUX M900 and 3080 K...

Page 17: ...Installation and operating instruction ALTOFLUX M900 and 3080 K 17 11 Limits...

Page 18: ...18 Installation and operating instruction ALTOFLUX M900 and 3080 K Notes...