12

OPERATING INSTRUCTIONS

Document: DOK-029

substances dissolved in CFC-containing solvents

abrasive or

corrosive materials.

Areas of application

The automatic spray gun can be used as an independ-

ent unit or as part of a larger system (e.g. as part of a

fully automatic spraying system or a spraying robot).

The automatic spray gun is particularly suitable for use

when relatively large material volumes per time unit are

to be processed. A further advantage compared to pneu-

matically operated spray guns is that less spraying mist

is created and a far higher percentage of the material

therefore reaches the workpiece.

BASIC DESIGN, MODE OF OPERATION

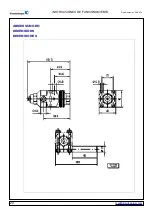

The design of the automatic spray gun type KAA-1300

is shown in the appendix; accessories and fastening

device are shown in the diagram 140-0084/1.

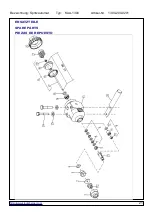

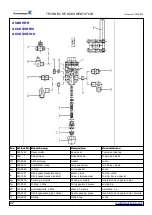

The automatic spray gun type KAA-1300 is equipped as

standard with two opposite material feed openings for

circulation connection. Double nipples (102) or angles

(103) can be used for the material connection, and an

angle screw connection (106) or swivel screw connec-

tion (107) is available for control air connection. This

allows adaptation of hose routing to suit the installation

situation on site. If material circulation is not required,

one of the material feed openings is closed using the

drain plug (104) and the sealing screw (105).

A pump supplies the material at a pressure of max. 2,5

MPa (250 bar) through a hose (which is designed to with-

stand the pressure load) to the material connection (102

or 103) of the automatic spray gun. The spraying process

is controlled by applying compressed air to the control

air connection (106 or 107). The air flowing into the air

chamber pushes the piston, cmpl. (16) and thus the valve

needle (17) backwards against the pressure of the spring

(21). This releases the front opening of the valve seat

screw (3), and the material flows at high pressure into

the material nozzle (112), where it is discharged in the

form of a flat, wide material jet onto the workpiece to be

coated.

(!) WARNING NOTE!

IN THE RISK OR THE EVENT OF AN ACCIDENT, THE

SPRAY JET CAN BE SHUT DOWN QUICKLY BY CLO-

SING THE SHUTOFF VALVE ON THE PUMP. DURING

INSTALLATION, ENSURE THAT THE SHUTOFF VALVE

IS EASILY ACCESSIBLE AT ALL TIMES!

i

Only Open/Close functions can be performed via the

control air. It is not possible to dose the spray jet via

the control air.

ASSEMBLY

Secure the cylindrical shaft (14 mm dia.) of the

retaining bolt (108) to a suitable clamping piece

(e.g. a cross, flange or joint clamping piece)

and screw the automatic spray gun type KAA-

1300 to the retaining bolt (108) using two

screws inserted through the fastening bore-

holes (B). The clamping piece can be mounted

on a rigid or a flexible device (e.g. a robot arm).

i

If the automatic spray gun is not adequately secured,

it may become loose during operation - e.g. due to

vibrations. There is also a risk of displacement due to

recoil. Under certain circumstances, the coating substan-

ce may escape in an uncontrolled manner.

i

If several automatic airless spray guns are feed simul-

taneously from a high-pressure material source, clo-

sing of the material feed on one or more automatic

units can lead to recoil changes in the other guns. The

recoil risk can be reduced by using elastic material feed

lines (e.g. high-pressure hoses instead of pipes).

(!) Caution!

Assembly should be performed by suitably

trained personnel only!

STARTUP

Connections

Material connection to double nipple (102) or

angle (103); in the case of circulation feed -

return flow connection to the storage container

on the opposite side. If the material circulation

option is to be remain unused, seal off one side

using a drain plug (104) and a sealing screw

(105).

Control air to angle screw connection (106) or

swivel screw connection (107).

(!)CAUTION!

COMPRESSED AIR AND MATERIAL FEED SHOULD

ONLY BE CONNECTED UP BY SUITABLY TRAINED

PERSONNEL! ENSURE THAT THE PRESSURES AND

TEMPERATURES LISTED UNDER “TECHNICAL DATA”

ARE NOT EXCEEDED!

i

Material feed is effected via a pump. A circulation con-

nection is recommended, for example, when using

settling coating substances or for materials whose

temperature has to kept constant. The automatic spray