REMARK

For the greasing to boom swing cylinder foot pin, it is the item to be performed in “WHEN REQUIRED”.

3.

Check visually that the greasing has been performed properly.

4.

After greasing, wipe off any old grease that is pushed out.

EVERY 250 HOURS MAINTENANCE

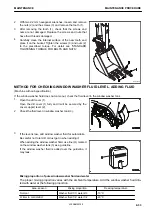

METHOD FOR CHECKING AND ADJUSTING AIR CONDITIONER COMPRESSOR

BELT TENSION

(Machine with cab specification)

1.

Pull the engine rear cover (1) toward you to open it.

Open the engine rear cover (1) fully and it is secured by

rod (2).

2.

Check the belt tension of air conditioner compressor.

Press the belt with a finger at a point midway between idle

pulley (3) and compressor (4). (approximately 58.8 N {ap-

proximately 6.0 kg} )

If deflection (a) is in the standard range (5 to 6 mm), the air

conditioner compressor belt tension is correct.

If deflection (a) is out of the standard range, adjust it according to the following procedure.

MAINTENANCE PROCEDURE

MAINTENANCE

4-44

WENAM00150

Summary of Contents for PC30MR-5

Page 2: ......

Page 66: ...WENAM00150 ...

Page 69: ... 14 Engine rear cover 15 Cooling cover 16 Battery OPERATION GENERAL VIEW 3 3 WENAM00150 ...

Page 325: ...SPECIFICATIONS 5 1 WENAM00150 ...

Page 363: ...REPLACEMENT PARTS 7 1 WENAM00150 ...

Page 370: ...WENAM00150 ...

Page 379: ......

Page 380: ......